Quick Summary: Selecting the right oval gear flow meter requires understanding four key factors: fluid properties (viscosity, compatibility, temperature), system requirements (flow rate, pipe size), output type (mechanical, digital, pulse), and special certifications (sanitary, high-temperature, heated jackets).

For your operations to be accurate, efficient, and safe, selecting the appropriate flow meter is essential. Because of their great accuracy and dependability, oval gear flow meters are a popular choice for many industries, particularly when measuring viscous fluids like oils, fuels, and chemicals.

As a type of positive displacement (PD) meter, they work by trapping a precise amount of liquid between two rotating oval-shaped gears and counting each parcel as it passes through. This direct volume measurement makes them incredibly accurate and less affected by changes in fluid properties.

Unlike other flow measurement technologies that rely on fluid velocity or differential pressure, oval gear meters measure volume directly. This makes them ideal for:

The first and most important step is to know the properties of the liquid you need to measure. Oval gear meters are designed for clean liquids, as solids can jam the gears and cause damage. Always plan to install a strainer or filter upstream of the meter to protect it.

Oval gear meters excel at handling a wide range of viscosities, but it's a critical factor in your selection:

Low Viscosity (less than 3 cP) - Examples: water, solvents, gasoline

For thin, water-like liquids, some fluid can "slip" between the gears and the chamber wall, which can affect accuracy at very low flow rates. To get the best results, you may need to operate at a slightly higher flow rate to maintain the meter's stated precision.

Medium Viscosity (3 to 1,000 cP) - Examples: diesel fuel, lubricating oils, vegetable oil

This is the ideal range for oval gear meters. They provide excellent accuracy with these fluids because there is minimal slippage.

High Viscosity (above 1,000 cP) - Examples: honey, grease, thick resins, molasses

Very thick fluids create more resistance, leading to a higher pressure drop across the meter. For these applications, look for meters with special "high viscosity" rotors that reduce pressure drop by up to 50% without sacrificing accuracy.

The flow sensor's materials must be able to withstand the liquid without corroding or degrading. This applies to every part that touches the fluid, known as "wetted parts."

| Component | Material Options | Suitable Applications |

|---|---|---|

| Body | Cast Iron (LC-A) | Fuels, oils, greases (non-corrosive) |

| Body | Cast Steel (LC-E) | High pressure, low-corrosive fluids |

| Body | Stainless Steel (LC-B, C) | Corrosive chemicals, food grade, pharmaceuticals |

| Rotors (Gears) | Aluminum/Cast Iron | Petroleum products, hydraulic oils |

| Rotors (Gears) | Stainless Steel | Edible oils, chemicals, corrosive liquids |

Ensure the meter you choose is rated to handle your system's normal operating temperature and pressure, as well as any potential maximums.

This is the primary factor that determines the size of the meter. You need to know the full range of flow your system will experience.

Example: If your normal flow is 25 GPM (95 L/min), choose a meter with a maximum capacity of around 40 GPM (150 L/min) for best performance.

The flow sensor must physically fit into your existing pipework. Oval gear meters are available with various connection types:

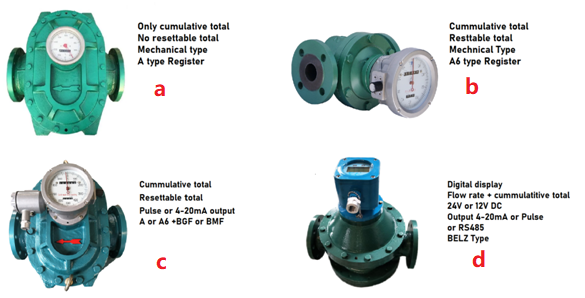

A. Mechanical Display Only

Simple, non-powered counter on the meter itself. Robust and reliable for local readings where you don't need system integration. No external power required.

B. Mechanical Display with Resettable Batch Totalizer

Includes a manually resettable counter for individual batch measurements. Perfect for filling operations where you need to track individual batches.

C. Electronic Output (Pulse or 4-20mA)

Mechanical display plus electronic signals that can be sent to PLCs, batch controllers, or remote displays. Ideal for automated systems and SCADA integration.

D. Integral Digital Display

Battery-powered or loop-powered LCD/LED display mounted on the meter. Shows real-time flow rate and total volume with multiple communication options (4-20mA, pulse, RS485, HART).

For liquids that easily solidify or are extremely viscous at ambient temperatures (asphalt, bitumen, heavy resins, chocolate), a meter with a heating jacket is essential. The jacket allows circulation of steam or hot oil to maintain fluid temperature and prevent solidification inside the meter.

For processes consistently above 60°C (140°F), high temperatures can damage electronic components. Meters equipped with cooling fins or heat sinks dissipate heat effectively, protecting the electronics and extending service life.

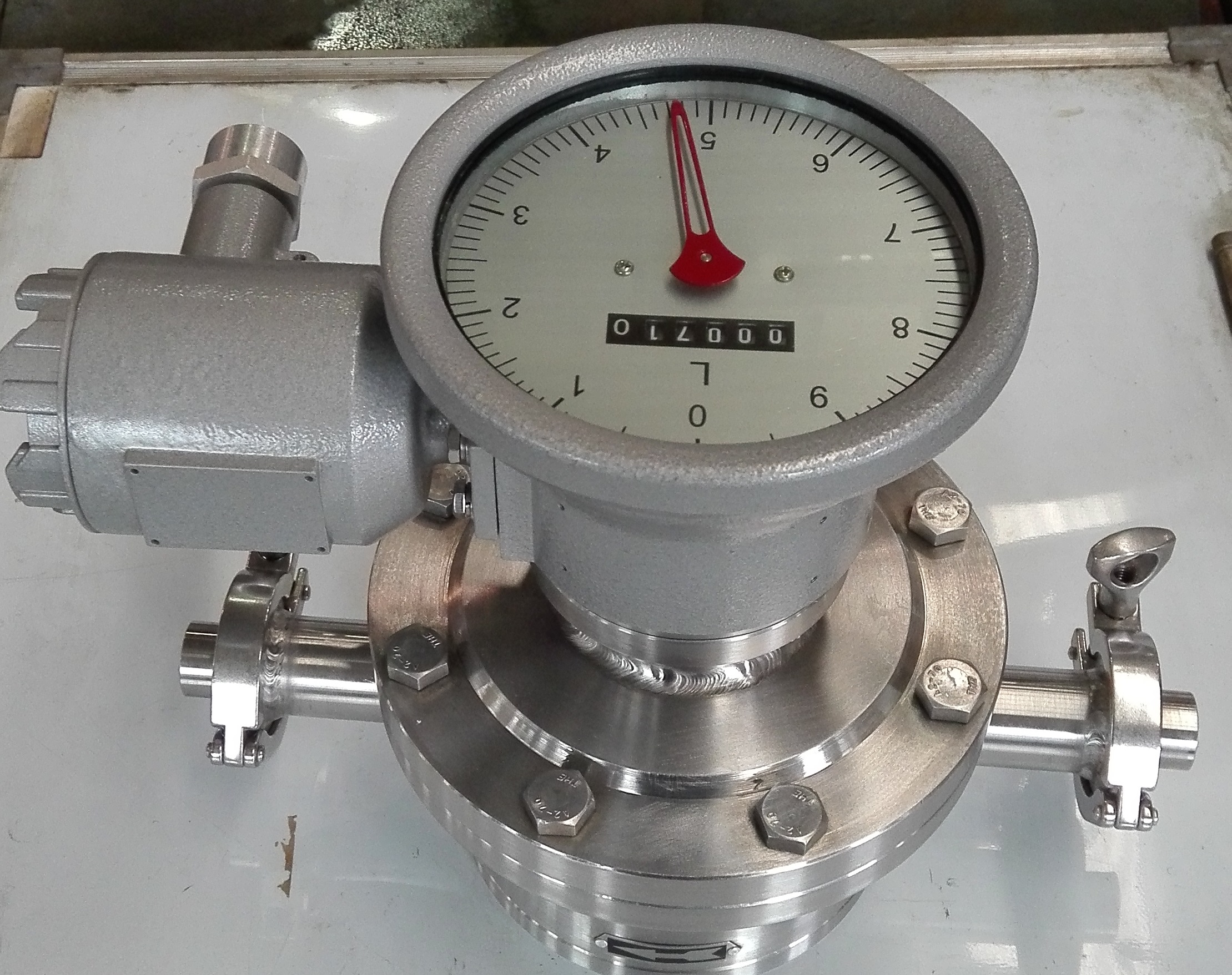

Food, beverage, and pharmaceutical applications require meters that meet strict hygienic design standards. Features include:

If measuring flammable liquids or operating in explosive atmospheres, ensure your meter has appropriate certifications:

By answering these questions, you can confidently choose the right oval gear meter:

Choosing the right oval gear flow meter doesn't have to be complicated. By systematically considering your fluid properties, system requirements, data needs, and any special certifications, you can select a meter that will provide accurate, reliable measurements for years to come.

This careful selection process is a small investment that pays off with:

Need help selecting the right meter for your application? Our technical team is available to provide free consultation and sizing assistance. Contact us today with your fluid properties and flow requirements.

Sanitary Oval gear flow meter2019/07/10Hygienic and sanitary oval gear style flow meter is kind of positive displacement (PD) flow meter which can be used in dairy,food processing industry or bio-technology industry; it has two rotating ov...VIEW

Sanitary Oval gear flow meter2019/07/10Hygienic and sanitary oval gear style flow meter is kind of positive displacement (PD) flow meter which can be used in dairy,food processing industry or bio-technology industry; it has two rotating ov...VIEW Mechanical register oval gear flow meter2019/07/09Mechanical counter oval gear flow meter is a kind of in-line positive displacement flow meter where main power is impossible in the field or the field only request basic metering, no output transmissi...VIEW

Mechanical register oval gear flow meter2019/07/09Mechanical counter oval gear flow meter is a kind of in-line positive displacement flow meter where main power is impossible in the field or the field only request basic metering, no output transmissi...VIEW High viscosity oval gear flow meter2019/06/04High viscosity oval gear flow meter can detect fluids viscosity 2000 cp. VIEW

High viscosity oval gear flow meter2019/06/04High viscosity oval gear flow meter can detect fluids viscosity 2000 cp. VIEW High temperature Oval gear flow meter2019/07/09High temperature oval gear flow meter with can handle liquid temperature up to 200°C(392℉), it Is equipped with cooling fin to decrease the high temperature effect on the flow meter transmitter. Thi...VIEW

High temperature Oval gear flow meter2019/07/09High temperature oval gear flow meter with can handle liquid temperature up to 200°C(392℉), it Is equipped with cooling fin to decrease the high temperature effect on the flow meter transmitter. Thi...VIEW Oval gear flow meter with pulser2019/07/09LC series oval gear flow meter with pulse output can have mechanical register also equip with a pulser to transfer pulse signals for other process control purpose. This gear driven flow meter is main...VIEW

Oval gear flow meter with pulser2019/07/09LC series oval gear flow meter with pulse output can have mechanical register also equip with a pulser to transfer pulse signals for other process control purpose. This gear driven flow meter is main...VIEW Stainless steel oval gear flow meter2019/05/22Oval gear flow meter is a kind of PD flow meter which measures the liquid constantly. Oval meter can be made into mechanical oil flow meter also made into digital type with various outputs VIEW

Stainless steel oval gear flow meter2019/05/22Oval gear flow meter is a kind of PD flow meter which measures the liquid constantly. Oval meter can be made into mechanical oil flow meter also made into digital type with various outputs VIEW