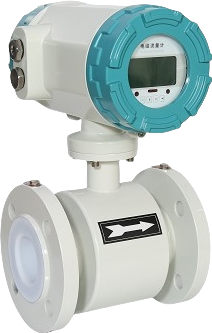

Magnetic Flow Meters for Wastewater Measurement

Accurate, reliable flow measurement for conductive liquids

Need a reliable way to measure sewage or wastewater flow?

A magnetic flow meter is your perfect solution — no moving parts, high accuracy, long service life.

It's the best choice for monitoring sewage, slurry, pulp, and other conductive liquids across industries like water treatment, mining, papermaking, and chemical plants.

Contact Us Now to get a professional quote for your sewage flow measurement project!

How Does a Magnetic Flow Meter Work?

Magnetic flow meters use Faraday's Law of Electromagnetic Induction to measure flow.

When wastewater flows through a magnetic field, it generates a voltage. The stronger the flow, the higher the voltage. Sensors on the pipe walls capture this voltage and instantly calculate the flow rate.

Each system consists of:

- Magnetic Flow Sensor – Measures the induced voltage from the liquid.

- Transmitter – Converts voltage into accurate flow data, sent to your control system.

Simple structure. No moving parts. Highly reliable — even in dirty, harsh wastewater conditions.

Why Choose Magnetic Flow Meters for Wastewater from silverinstruments.com?

- No Moving Parts: Minimal wear and tear, longer lifespan.

- Energy Efficient: Some models require as little as 15 watts.

- Handles Corrosive Fluids: Internal linings resist strong acids and bases.

- Bi-Directional Flow meter for sewage: Measures forward and reverse flows easily.

- Minimal Metal Use: Fewer components reduce failure risks.

- Full-bore flow meter: No pressure loss.

- China Factory price: With reliable working for more than 15 years.

- Fast delivery time: Most mag meters can be shipped within 7 days.

Need a quote? Talk to our flow experts now!

Key Specifications to Consider

When selecting your wastewater flow meter, focus on:

- Conductivity of the fluid

- Required measurement accuracy

- Flow speed (velocity)

- Installation environment

- Pipe size, flow range, operation pressure and design

- Pipeline full of water or not

We help you choose the right model based on your project needs, not just the price tag.

How to Install a Wastewater Magnetic Flow Meter?

- Install the meter with electrodes aligned horizontally.

- Make sure the pipe is always full of liquid for stable readings.

- Keep the installation area away from strong electromagnetic fields.

- Use supports if pipes vibrate.

- For mixtures of liquids, install at least 30 pipe diameters away from the mixing point.

- Use a torque wrench carefully when tightening bolts, especially for PTFE-lined meters.

Proper installation = longer service life + better performance.

Need magmeter installation guidance? Message us today!

Looking for Reliable and Affordable Sewage Flow Meters?

Big brands like ABB, Krohne, Yokogawa, Siemens offer magnetic flow meters — but at a premium price.

At Silver Automation Instruments, we supply durable, accurate, and economical magnetic flow meters that deliver top-brand performance without the hefty price tag.

Save money without sacrificing quality!

Get your free consultation and best pricing now!

Final Word

Choosing the right sewage flow meter is critical.

For best results, trust qualified technicians for installation and calibration.

And if you're looking for a high-quality, cost-effective wastewater flow meter — we're here to help!

Leave us a message today — let's find the right solution for your wastewater flow measurement!

English

English  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  Türkçe

Türkçe  ไทย

ไทย  українська

українська  Malay

Malay  עברי

עברי  Indonesia

Indonesia  Ελλάδα

Ελλάδα  ಕನ್ನಡ

ಕನ್ನಡ  հայերեն

հայերեն

Email

Email

WA

WA

Inquiry

Inquiry