Measuring the flow of high viscosity liquids is one of the most demanding tasks in industrial instrumentation. Fluids such as heavy oils, asphalt, resins, and molasses are thick, difficult to pump, and present unique challenges for accurate measurement. Unlike low viscosity fluids like water or milk that flow easily, these thick liquids require specialized flow meter technologies to ensure process efficiency, product consistency, and reliable inventory management. An incorrect meter choice can lead to inaccurate readings, high pressure drops, and even complete measurement failure.

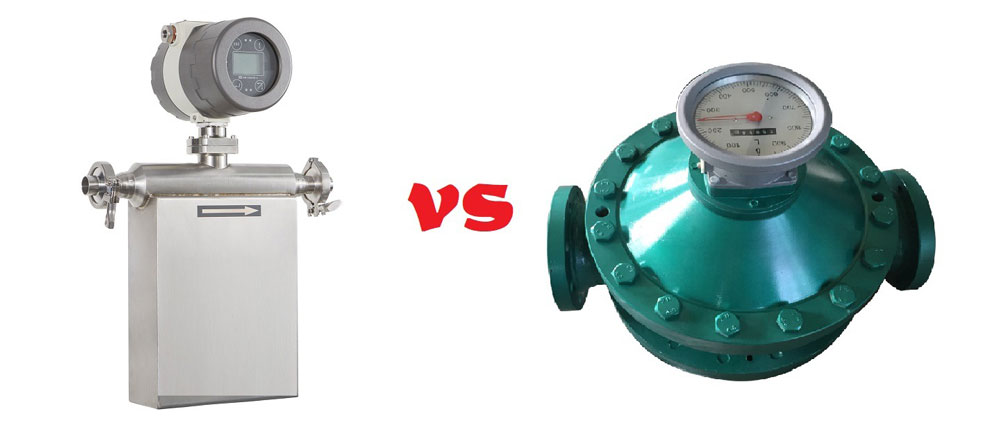

This guide provides an in-depth analysis of the best flow meter technologies for high viscosity fluids. We will compare the two primary solutions—Coriolis mass flow meters and Oval Gear positive displacement meters—and explore their ideal applications across various industries, helping you select the perfect instrument for your challenging process.

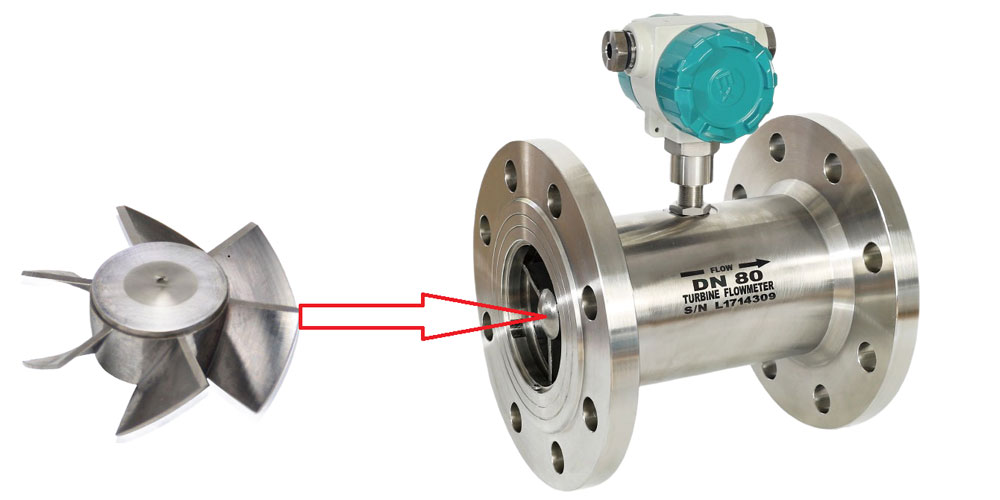

High viscosity creates several problems for standard flow meters. Velocity-based technologies, such as turbine or orifice plate meters, rely on a uniform, turbulent flow profile to function correctly. Viscous fluids, however, often exhibit laminar flow, where the fluid moves faster at the center of the pipe than at the edges. This non-uniform profile can lead to significant inaccuracies. Furthermore, the thick nature of the fluid can clog or damage the moving parts of mechanical meters, leading to frequent maintenance and downtime.

For decades, two technologies have proven to be the most reliable and accurate for handling viscous fluids: Positive Displacement meters (specifically Oval Gear) and Coriolis Mass Flow Meters.

Oval Gear meters are a type of Positive Displacement (PD) flow meter. They function like a highly precise fluid engine, using two interlocking gears to trap and pass a precise, known volume of liquid with each rotation. Because they directly measure volume, they are highly accurate and largely unaffected by the fluid's viscosity.

For applications that require precise measurement of high viscosity fluids at very low flow rates—such as chemical dosing, additive injection, or in laboratory settings—the small oval gear flow meter is an ideal solution. These compact positive displacement meters operate on the same reliable principle as their larger counterparts but are specifically engineered for flow ranges often below 1 L/min. They provide a highly accurate, cost-effective alternative to Coriolis meters for small-volume, high-viscosity applications where the fluid is clean. Below video to show how our small oval gear flwo meter work for the high visocisty liquid flow measurement:

Choosing between these two excellent technologies depends on your specific application. Here are three simple rules to guide your decision:

| Feature | Coriolis Mass Flow Meter | Oval Gear Flow Meter |

|---|---|---|

| Measurement Principle | Direct Mass Flow (Coriolis Effect) | Volumetric (Positive Displacement) |

| Handles Solids/Slurries? | Yes, excellent performance | No, for clean fluids only |

| Max Viscosity | Extremely High (500,000+ cP) | High (up to 2,000 cP or more) |

| Outputs | Mass, Volume, Density, Temperature | Volume (with options for pulse/analog) |

| Straight Pipe Run Needed? | No | No |

| Initial Cost | Very High | Low to Medium |

High viscosity flow meters are essential in a wide range of industries across the globe. Below are some of the most common applications where our instruments provide critical data.

The chemical industry relies on high-accuracy meters for dosing resins,glucose, lecithin, polymers, solvents,grease, paste and other viscous chemicals. The material compatibility of Coriolis and stainless steel oval gear meters is critical in these applications.

Precise fuel oil measurement is crucial for efficiency in industrial furnaces and boilers, ensuring optimal combustion and cost control. This often involves thick, pre-heated oils that are easily handled by Coriolis or oval gear meters.

In paper mills, Coriolis meters are used to measure the flow of thick paper pulp slurries and coating chemicals, where other meters would quickly clog and fail.

Many viscous fluids, like asphalt and bitumen, must be measured at extreme temperatures. Our specialized high-temperature flow meters, particularly Coriolis models, are engineered to handle these demanding conditions with exceptional reliability.

The successful measurement of high viscosity fluids hinges on selecting the right technology for your specific process. While an oval gear meter provides a cost-effective, high-accuracy solution for clean liquids, the Coriolis mass flow meter offers unmatched versatility for the most challenging applications involving slurries, extremely high viscosities, or the need for direct mass measurement.

At Silver Automation Instruments, we specialize in providing robust solutions for even the most difficult flow applications. Our team of experts can analyze your process data and help you choose the ideal instrument to deliver the accuracy and reliability you demand.

Contact Our Experts for a Consultation Coriolis Mass Flow Meter2017/04/12Direct mass flow measurement.

Coriolis Mass Flow Meter2017/04/12Direct mass flow measurement. Low flow high viscosity flow meter2019/07/13Oval gear flow meter and Coriolis mass flow meter are both suitable instruments for low flow and high viscosity flow rate measurement, the viscous fluids including: latex, crude oil, tooth paste ,resi...VIEW

Low flow high viscosity flow meter2019/07/13Oval gear flow meter and Coriolis mass flow meter are both suitable instruments for low flow and high viscosity flow rate measurement, the viscous fluids including: latex, crude oil, tooth paste ,resi...VIEW High viscosity oval gear flow meter2019/06/04High viscosity oval gear flow meter can detect fluids viscosity 2000 cp. VIEW

High viscosity oval gear flow meter2019/06/04High viscosity oval gear flow meter can detect fluids viscosity 2000 cp. VIEW Microfluidic Flow Meter2019/07/05LC-M Series Micro oval Gear flow meter candetect ultra mini liquid flow as low as 0.5 ml/min, but can still keep accuracyas high as 0.5%F.S, It is a kind of positive displacement flow meter forprecise...VIEW

Microfluidic Flow Meter2019/07/05LC-M Series Micro oval Gear flow meter candetect ultra mini liquid flow as low as 0.5 ml/min, but can still keep accuracyas high as 0.5%F.S, It is a kind of positive displacement flow meter forprecise...VIEW Stainless steel oval gear flow meter2019/05/22Oval gear flow meter is a kind of PD flow meter which measures the liquid constantly. Oval meter can be made into mechanical oil flow meter also made into digital type with various outputs VIEW

Stainless steel oval gear flow meter2019/05/22Oval gear flow meter is a kind of PD flow meter which measures the liquid constantly. Oval meter can be made into mechanical oil flow meter also made into digital type with various outputs VIEW Bent tube Coriolis flow meter2019/07/22Smaller installation size.

Bent tube Coriolis flow meter2019/07/22Smaller installation size. High pressure Coriolis flow meter2019/06/11Max work on 700 bar high pressure.

High pressure Coriolis flow meter2019/06/11Max work on 700 bar high pressure. Sanitary and hygienic Coriolis flow meter2019/06/12Tri-clamp or DIN 11851 end fitting

Sanitary and hygienic Coriolis flow meter2019/06/12Tri-clamp or DIN 11851 end fitting 4 inch coriolis flow meter2019/07/104 inch size Coriolis Mass Flow Meter is operated with Coriolis Force Principle. 4” Coriolis flow sensor is relative large size, and the flow meter is really bulky. It is widely used for accurate mass...VIEW

4 inch coriolis flow meter2019/07/104 inch size Coriolis Mass Flow Meter is operated with Coriolis Force Principle. 4” Coriolis flow sensor is relative large size, and the flow meter is really bulky. It is widely used for accurate mass...VIEW Oval gear flow meter with pulser2019/07/09LC series oval gear flow meter with pulse output can have mechanical register also equip with a pulser to transfer pulse signals for other process control purpose. This gear driven flow meter is main...VIEW

Oval gear flow meter with pulser2019/07/09LC series oval gear flow meter with pulse output can have mechanical register also equip with a pulser to transfer pulse signals for other process control purpose. This gear driven flow meter is main...VIEW Oval gear flow meter with return to zero counter2019/07/09LC oval gear flow meter is equipped with mechanical counter which could also add with return-to-zero function. This kind of flow meter counter has 2 digits wheels, one for total flow totalizing; anoth...VIEW

Oval gear flow meter with return to zero counter2019/07/09LC oval gear flow meter is equipped with mechanical counter which could also add with return-to-zero function. This kind of flow meter counter has 2 digits wheels, one for total flow totalizing; anoth...VIEW Oval gear flow meter with external heat jacket2019/07/09LC series oval gear flow meter with external heated measuring loops is suitable for high viscosity fluids measurement, such as asphalt, bitumen or tar flow rate measurement. VIEW

Oval gear flow meter with external heat jacket2019/07/09LC series oval gear flow meter with external heated measuring loops is suitable for high viscosity fluids measurement, such as asphalt, bitumen or tar flow rate measurement. VIEW