What is compressed air mass flow meter ?

Compressed air mass flowmeter, in simple terms, is an instrument that directly measures "how many kilograms of air flow through the pipeline”, with flow rate units like kg/hr, t/h. It is not like traditional vortex flow meter or orifice flow meters, which measure "volumetric flow" (m3/h). This varies greatly in compressed air systems - because the volume of compressed air changes dramatically with pressure and temperature, but the mass remains constant. For example, the "cubic meters (m3)" consumed by the same device under different pressures may differ by several times, but the "kilograms (kg)" which is mass flow are basically stable. So, in scenarios where pressure fluctuations are common in compressed air, measuring with mass flow rate truly reflects the actual energy consumption and usage.

Why is my compressed air flow measurement always inaccurate?

The most common reasons for inaccurate measurement of compressed air systems are as follows. Firstly, there are pressure and temperature fluctuations. Many sites only install a pressure gauge at the outlet of the flow meter, ignoring the density changes caused by upstream pressure changes, especially in systems where multiple air compressors are connected in parallel or frequently loaded and unloaded. The temperature effect is equally crucial, as readings of indoor and outdoor pipelines may differ by more than 10% between summer and winter.

Next is pipeline turbulence. The most common problem on site is installing compressed air flow meters immediately after elbows, valves, or reducers. After passing through these components, air will generate violent vortices, requiring a sufficiently long straight pipe section (usually requiring 10 times the diameter of the upstream pipe and 5 times the diameter of the downstream pipe) to restore smooth flow. Many factories install air flow sensors within a few meters of the air compressor outlet to save time, but the readings jump sharply.

Furthermore, there is condensation water and oil mist. Compressed air inevitably carries oil and water, and if these impurities adhere to the sensor, especially the probe of the thermal flowmeter, they will seriously affect the heat dissipation characteristics, leading to reading drift or even damage. Many sites only install filters in the main pipeline, neglecting secondary filtration in front of branches or instruments.

How to choose the right compressed air mass flow meter?

Compressed air flow range and pipeline size, operation temperature and pressure

The selection first requires providing the pipe diameter and flow range. The flow range should provide three values: minimum, common, and maximum, especially the minimum flow - many compressed air flow sensors experience a sharp decrease in accuracy at low flow rates. Secondly, work pressure and temperature should not only be considered based on conventional values, but also extreme working conditions.

Air quality is often overlooked.

To clarify the pressure dew point and oil content of the system, most flow meters can handle air below ISO 8573-1 standard Class 2 (pressure dew point -40 ° C, oil content ≤ 0.1 mg/m ³); If it is more humid or oily, it is necessary to choose a air flow sensor with anti pollution design.

Digital compressed air with analog outputs or digital communication

The output signal is determined according to the control system: 4-20mA analog output is the most universal, Modbus RTU is suitable for data acquisition, and HART is convenient for on-site debugging. Accuracy does not need to be blindly pursued - for energy consumption monitoring, a repeatability of ± 1.5% is often more practical than an accuracy of ± 1%.

Thermal flowmeter for compressed air mass flow measurement

Thermal masss flow meter for compressed air

Principle

Thermal mass flow meters are particularly suitable for compressed air because they directly measure mass flow rate. The principle is simple: there are two temperature sensors on the probe, one is heated and the other senses the temperature of the airflow. When air flows through, it takes away heat, and the larger the flow rate, the faster the heat dissipation. The mass flow rate can be calculated by changing the heating power.

Advantages

Its biggest advantage is that it does not require pressure and temperature compensation (in scenarios where pressure is relatively stable), and it is extremely sensitive to low flow rates, the turndown ratio can reach to 100:1, capturing a gentle wind speed of 0.1 meters per second, which is very beneficial for leak detection. But it is indeed delicate - afraid of water, oil, and dust. If the air quality is poor, the probe is prone to fouling and needs to be cleaned or even replaced regularly. In addition, it has high installation requirements and significant errors when the straight pipe section is insufficient.

What kind of air suitable for thermal mass flow meter

So thermal mass flow meter is suitable for dry, clean, and pressure stable compressed air systems, such as clean air sources in electronics and pharmaceutical factories. But it is not suitable for damp and oily environments with severe pressure fluctuations, such as old air compression stations or oil lubrication systems.

The vortex flowmeter with temperature and pressure compensation is a practical approach in compressed air mass measurement.

Vortex flow meter with temperature and pressure compensation

Principle

Its principle is "numerical vortex" - when the airflow passes around the probe, a vortex column is generated, and the frequency is proportional to the flow velocity. But what is measured is the volumetric flow rate under working conditions, while the volume of compressed air varies dramatically with pressure and temperature. Therefore, the core lies in compensation: the vortex flow sensor needs to collect pressure and temperature signals in real time, convert the operating flow rate into standard flow rate (Nm ³/h) or mass flow rate (kg/h), and the data is meaningful.

Advantages

The advantages are obvious: compared to the thermal mass flow meter type, it is more resistant to dirt and less sensitive to common oil mist and condensed water in compressed air; No moving parts, stable and durable; And its cost-effectiveness is outstanding at medium to high flow rates.

Disadvantages

Shortcomings are also clear: afraid of low flow rates, accuracy usually decreases or even cannot be measured when the flow rate is below 2-3 m/s, making it difficult to capture small leaks; I am also afraid of pipeline vibration. If the vibration frequency is close to the vortex frequency, it will cause interference.

Therefore, it is suitable for installation in main pipelines, with stable pressure and moderate to high flow rates, such as at the outlet of air compression stations and workshop main pipelines, for reliable energy total accounting. It provides compensated, stable and comparable data, making it the economic choice for system measurement.

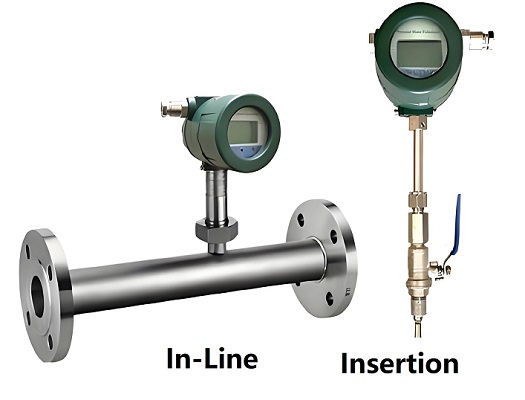

Insertion mass flow meter or in-line mass flow meter?

Inline or insertion compressed air mass flow meter ?

This mainly focuses on monitoring the pipeline size and budget. The installation cost of insertion air mass flow meter is low, and there is no need to stop production and cut pipes. It can be installed in two hours by one team, which is very suitable for the renovation of large-diameter pipelines with a diameter of DN80 or more. But its accuracy is usually around ± 2% for insertion vortex flow meter and it is greatly affected by the flow velocity distribution. Good news is that insertion thermal mass flow meter and inline thermal mass flow meter has the same accuracy.

The inline type has higher accuracy (up to ± 1%) and good stability, but it is expensive, difficult to install, and requires cutting the pipeline. It is suitable for new projects or occasions with high measurement accuracy requirements when install vortex flow meter (such as trade settlement). Simple principle: For DN200 and below, pipe section type is preferred, while for DN300 and above, plug-in type has higher cost-effectiveness.

What if there is not enough straight pipe for compressed air mass flow measurement?

If there are not enough straight pipe sections on site (such as limited space in the computer room), there are several alternative solutions: first, install a pipeline rectifier to disperse the vortex and reduce the requirement for straight pipe sections from 10D to 5D; second, move the flow meter further downstream, even if several tens of meters of pipeline are used, the reading will be much more stable.

Compressed air flow measurement units

Unit conversion is the easiest to confuse. Nm ³/h is the standard flow rate (0 ° C, 1 atmosphere), m ³/h is the operating flow rate (at actual temperature and pressure), and SCFM is the American standard cubic feet per minute (21 ° C, 1 atmosphere). Compressed air contracts are often settled in Nm ³/h, but the flow meter outputs kg/h or actual m ³/h, which needs to be converted based on real-time pressure and temperature. A reliable approach is to have the flowmeter directly output Nm ³/h with compensation to avoid later calculation errors.

FAQ

Q: Can we measure humid air by compressed air mass flow meter?

A: Sure, but containing liquid water can affect air flow meter accuracy ,especially for thermal mass flow meter, so it is necessary to ensure that the air at the measurement point does not condense.

Q: Can compressed air mass flow meter detect minimum measurable flow rate?

A: The minimum speed of the thermal mass flow meter is about 0.05 m/s, which is equivalent to about 1.4 Nm ³/h for a DN100 compressed air flow meter.

Q: Will the reading change as the pressure increases?

A: The mass flow rate theoretically remains unchanged, but the sensor may experience zero drift when subjected to pressure, and a pressure resistant matching model should be selected.

Q: Can compressed air flow meter display Nm ³/h flow ?

A: Normally thermal mass flow meter can directly display Nm3/h, while vortex flow meter needs pressure and temperature compensation are available display air flow with Nm3/h flow unit.

Q: Is it suitable for large pipe diameters/ultra-low flow rates?

A: For DN200 and above, use insertion air flow sensor ; Ultra low flow selected thermal micro flow special type, with a range ratio of up to 100:1.

Ultimately, measuring compressed air mass flow is not something that can be solved by buying a high-precision instrument. It is a system engineering, from selection, installation to maintenance, every link may introduce errors. Understanding principles, recognizing operating conditions, and standardizing installation are more important than simply pursuing instrument accuracy. On site, a properly installed medium precision instrument is often much more reliable than a randomly installed high-precision air mass flow meter.

Contact sales@silveinstruments.com to choose a proper and low cost compressed air mass flow meter for you.

Air flow meter with 4-20mA output2019/08/08Silver Automation Instruments specializes in supplying of a wide range of inline or insertion air flow meters with analog 4-20mA output. We have many types air flow meter which can take measurement o...VIEW

Air flow meter with 4-20mA output2019/08/08Silver Automation Instruments specializes in supplying of a wide range of inline or insertion air flow meters with analog 4-20mA output. We have many types air flow meter which can take measurement o...VIEW SCFM air flow meter2019/07/14Thermal mass flow meter with digital display to show air instant flow and air total flow:Instant flow units available :SCFM,g/min,g/s,Kg/min,Kg/h,Nm3/h,Nm3/min,NL/h,NL/min,Total flow units available:CFM,g...VIEW

SCFM air flow meter2019/07/14Thermal mass flow meter with digital display to show air instant flow and air total flow:Instant flow units available :SCFM,g/min,g/s,Kg/min,Kg/h,Nm3/h,Nm3/min,NL/h,NL/min,Total flow units available:CFM,g...VIEW In-line air flow meter2019/05/20Air flow rate measurement, also compressed air is vital demand in many factories, industry, lab, facilities.We, Silver Automation Instruments, have in-line air flow meters for sale, we have low price ...VIEW

In-line air flow meter2019/05/20Air flow rate measurement, also compressed air is vital demand in many factories, industry, lab, facilities.We, Silver Automation Instruments, have in-line air flow meters for sale, we have low price ...VIEW High temp air flow meter2019/07/10For max 350°C (662°F) high temperature.

High temp air flow meter2019/07/10For max 350°C (662°F) high temperature. Flanged Vortex flow meter with compensation2019/07/02STLU-BPT Series Flanged Vortex flow meter with integrated temperature sensor and pressure sensor compensation is a perfect choice for gas or steam (saturated steam and overheated steam) flow measureme...VIEW

Flanged Vortex flow meter with compensation2019/07/02STLU-BPT Series Flanged Vortex flow meter with integrated temperature sensor and pressure sensor compensation is a perfect choice for gas or steam (saturated steam and overheated steam) flow measureme...VIEW Micro air flow meter2019/07/14Micro-flowrate thermal dispersion flow meter is designed on the basis of thermal dispersion, and adopts method of constant differential temperature to measuring air at very low flow. It has advantages...VIEW

Micro air flow meter2019/07/14Micro-flowrate thermal dispersion flow meter is designed on the basis of thermal dispersion, and adopts method of constant differential temperature to measuring air at very low flow. It has advantages...VIEW Compressed air flow meter2019/06/20SRK-100 series Thermal-dispersion mass-flow is ideal for compressed air flow measurement. Compressed air flow measurement is important in energy saving industry, we need air flow instruments to monito...VIEW

Compressed air flow meter2019/06/20SRK-100 series Thermal-dispersion mass-flow is ideal for compressed air flow measurement. Compressed air flow measurement is important in energy saving industry, we need air flow instruments to monito...VIEW Bent tube Coriolis flow meter2019/07/22Smaller installation size.

Bent tube Coriolis flow meter2019/07/22Smaller installation size. Coriolis mass flow meter2019/06/12Best accuracy flow meter

Coriolis mass flow meter2019/06/12Best accuracy flow meter Large size Coriolis mass flow meter2019/06/12Large size: 4 inch,5 inch, 6 inch, 8 inch, 10 inch,12 inch.

Large size Coriolis mass flow meter2019/06/12Large size: 4 inch,5 inch, 6 inch, 8 inch, 10 inch,12 inch. 4 inch coriolis flow meter2019/07/104 inch size Coriolis Mass Flow Meter is operated with Coriolis Force Principle. 4” Coriolis flow sensor is relative large size, and the flow meter is really bulky. It is widely used for accurate mass...VIEW

4 inch coriolis flow meter2019/07/104 inch size Coriolis Mass Flow Meter is operated with Coriolis Force Principle. 4” Coriolis flow sensor is relative large size, and the flow meter is really bulky. It is widely used for accurate mass...VIEW Wafer Vortex flow meter with compensation2019/07/02STLU-BPT wafer style process connection vortex shedding flow meter with integral temperature and pressure compensation is a perfect choice for gas or steam (saturated steam and overheated steam) flow ...VIEW

Wafer Vortex flow meter with compensation2019/07/02STLU-BPT wafer style process connection vortex shedding flow meter with integral temperature and pressure compensation is a perfect choice for gas or steam (saturated steam and overheated steam) flow ...VIEW