In wood processing, biomass power generation, and papermaking industries, level measurement in wood sawdust silos has long posed significant challenges. This seemingly simple material presents three major level measurement pitfalls:

Measurement Challenges:

1. Dust Interference: Fine wood dust creates "measurement fog" during conveying, the flying dust poses a challenge to level measurement of wood chip.

2. Varying Angle of Repose: Fluctuations between 35°-55° depending on moisture content

3. Low Dielectric Constant (ε≈1.8-2.5) causing weak signal reflection

4. Bridging Phenomena: Fiber interlocking creates cavities and false level signals

Fiber interlocking creates cavities and false level signals

Limitations of Conventional level Measurement Technologies

- Ultrasonic Level Transmitters:

Dust absorbs acoustic waves, causing >15% measurement drift

When sawdust accumulates, the gaps are relatively large, and the measurement effect of

ultrasonic level gauge is poor.

- Submersible Pressure Transmitters:

Wood fibers entangle probes causing permanent damage. submersible pressure transmitters are used to measure liquid level , such as water, diesel, fuel oil , not suitable for wood chips.

80GHz Radar Level Transmitter: Revolutionizing Wood Chip Measurement

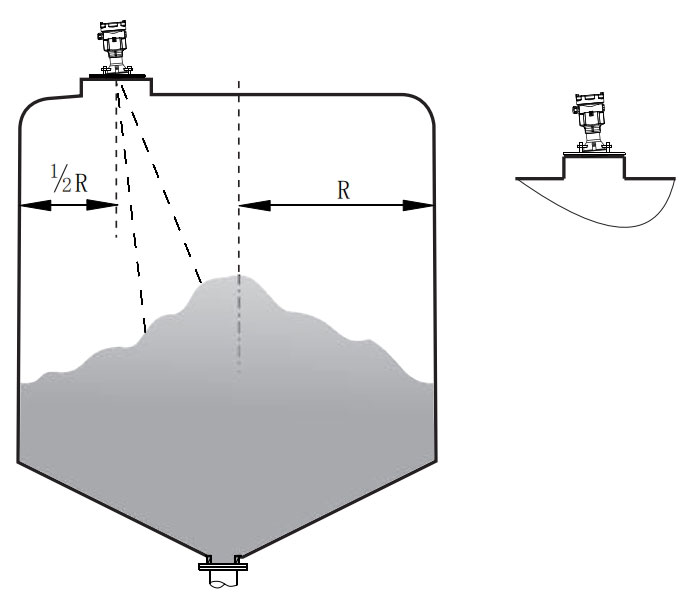

Utilizing Frequency Modulated Continuous Wave (FMCW) technology with 78-82GHz high-frequency microwaves. The 3.6mm wavelength (one-third of conventional 26GHz radar) combined with 12° narrow beam angle enables precise focusing:

1. High-frequency microwaves penetrate dust clouds

2. Narrow beam avoids wall interference

3. Dynamic surface tracking algorithm handles irregular surfaces

4. Echo enhancement technology compensates for weak reflections

|

Parameter

|

Ultrasonic

|

26GHz Radar

|

80GHz Radar

|

|

Dust Penetration

|

≤30%

|

≤50%

|

≤85%

|

|

Beam Angle

|

12°-15°

|

20°

|

3°-12°

|

|

Min. Dielectric Constant

|

N/A

|

≥2.0

|

≥1.5

|

|

Bridging Detection

|

None

|

Limited

|

Intelligent

|

Key Technical Specifications of wood chip level transmitter:

- Frequency Range: 78-82GHz (λ=3.6mm)

-Max silo level can reach to 120m

- Accuracy: ±2mm (even in 10m~20m high silos)

- Adjustable Beam Angle: 3°/6°/12° (software-configurable)

- Process Temperature: -40~200°C (with air purge interface)

- Antenna Materials: PTFE sealed/ceramic (anti-clogging)

- Signal Processing: 64 spectra/sec + AI echo pattern recognition

- Output 4-20mA, option with HART and MODBUS RTU

- Universal flange adjustment angle, suitable for solid measurement, flange size can be 3”,4”,5”6” and 8 inches.

Gimbal flange for solid wood chip measurement

Industrial Case Study:

A biomass power plant achieved after implementing 80GHz radar:

1. Measurement stability increased from 68% to 99.2%

2. Annual maintenance savings: CNY 400,000

3. Silo utilization improved by 22%

4. Eliminated bridging-related downtime