What is an SCCM Flow Meter?

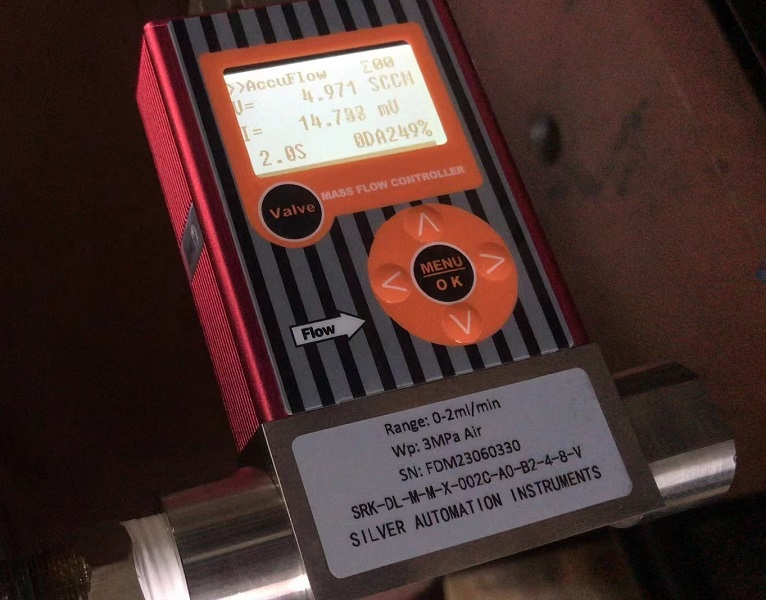

An SCCM flow meter is a precision instrument used to measure very small gas or air flow rates, typically expressed in SCCM (Standard Cubic Centimeters per Minute),such as 2 sccm, 10 sccm or 20

ml/min, The term “standard” means that the flow rate is referenced to specific temperature and pressure conditions, often 0°C and 1 atm, allowing for consistent and comparable readings across different applications. For more information about standard and actual gas conditions, please see this article:

[m³/h vs Nm³/h vs Sm³/h: The Ultimate Guide to Gas Flow Rate Units ] .

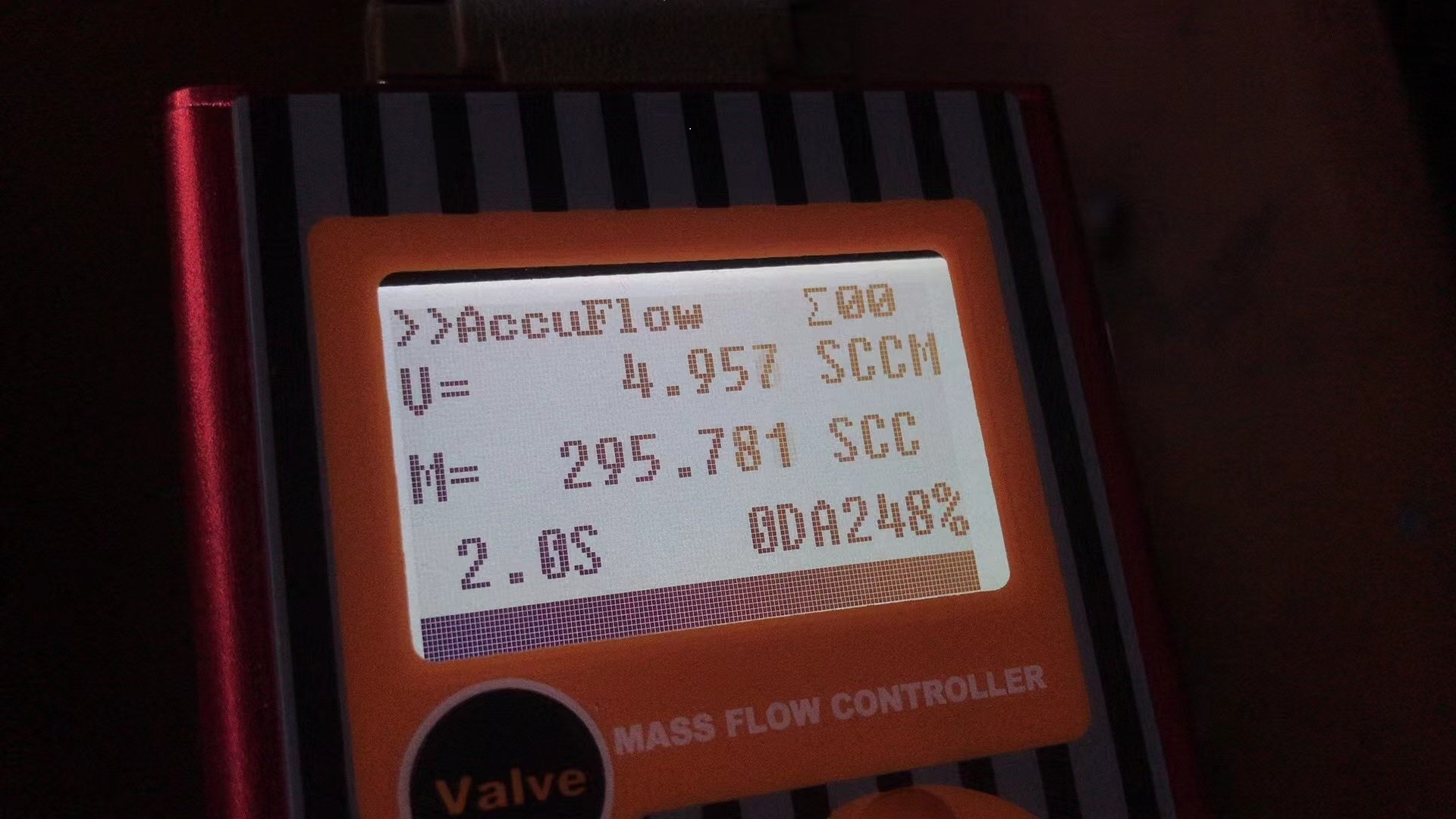

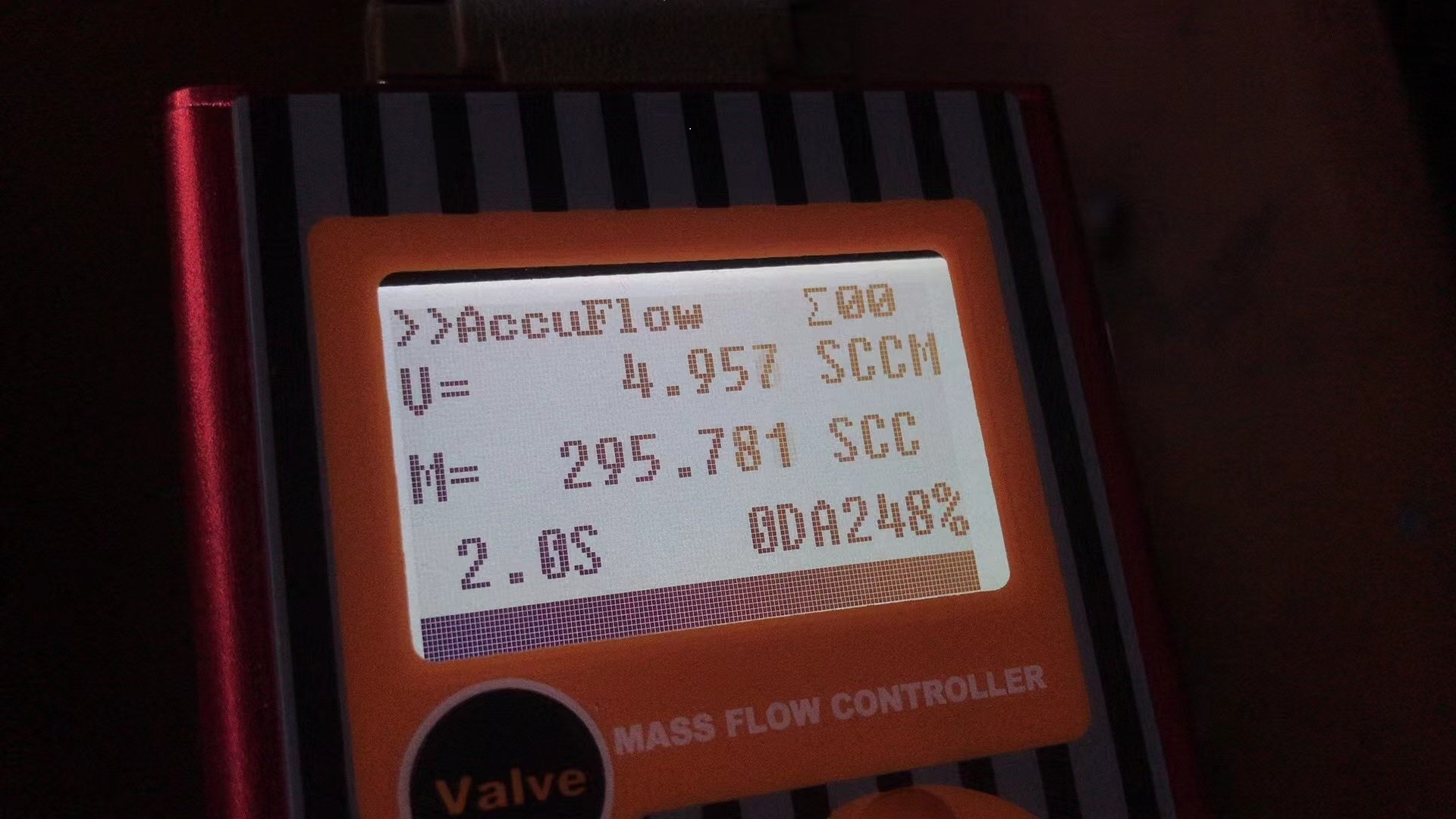

sccm flow unit micro gas flow meter

Unlike typical industrial

gas flow meters that handle large volumes of gas (with flow unit like MMscfd or GPM or m3/h) , SCCM flow meters are designed for micro-gas flow measurement. They are widely used in industries where precise gas control is critical — such as semiconductor manufacturing, laboratory research, medical device production,gas leak detection and analytical instrumentation. Even the smallest change in gas flow can significantly affect process quality and product yield in these fields.

Why SCCM Flow Measurement Matters

How SCCM Flow Meters Work

SCCM flow meters can be based on different measurement principles. The two most common types are thermal mass flow meters and differential pressure flow meters.

A micro thermal mass flow meter measures gas flow based on heat transfer. Inside the sensor, a small heater warms part of the gas stream, and temperature sensors monitor how quickly the heat is carried away by the gas. The faster the gas moves, the more heat is removed.

Because this method depends on the thermal properties of the gas, it measures mass flow rate directly — without needing temperature or pressure compensation. This makes it ideal for applications where the gas composition and operating conditions are stable.

Micro thermal flow meters with ml/min flow units are especially suitable for low-pressure, low-flow gas measurement, offering high accuracy, excellent repeatability, and fast response time.

Another common approach is the differential pressure (DP) flow meter. It works by placing a restriction (such as an orifice or laminar flow element) in the gas path. As gas flows through the restriction, it creates a pressure drop proportional to the flow rate.

By measuring this pressure difference, and knowing the gas density, the system can calculate the volumetric or mass flow rate. For micro-flow measurement in SCCM units, the DP element must be carefully designed to create measurable pressure differences even at very low flow rates.

DP-based SCCM meters are known for robust performance and compatibility with various gases, but they typically require temperature and pressure correction to maintain high accuracy.

Applications of SCCM Flow Meters

SCCM flow meters are essential tools in any process involving precise gas control. Some typical applications include:

-

Semiconductor and Electronics Manufacturing

Used for controlling carrier gases, deposition gases, and plasma etching systems. SCCM accuracy ensures stable wafer production and consistent quality.

In R&D labs, scientists use SCCM flow meters for gas chromatography, spectroscopy, and reaction kinetics studies, where precise gas dosing is required.

-

Pharmaceutical and Biotechnology

They regulate gas supply in fermenters, bioreactors, or sterilization chambers, maintaining optimal growth or reaction conditions.

-

Environmental and Analytical Equipment

SCCM flow meters help monitor air sampling, gas calibration systems, and emission analysis, ensuring trace gases are correctly measured.

-

Medical and Life Science Devices

In applications such as respiratory therapy, anesthesia, and gas mixing systems, SCCM-level control ensures patient safety and equipment accuracy.

Importance of Accuracy and Stability

SCCM flow meters must deliver exceptional accuracy, often within ±1% of reading or better. Sensitivity and zero stability are also critical — even minor drift can cause significant errors in long-term operations.

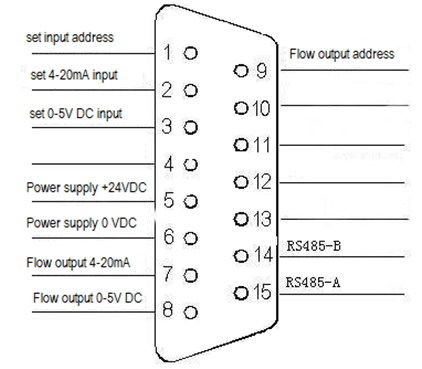

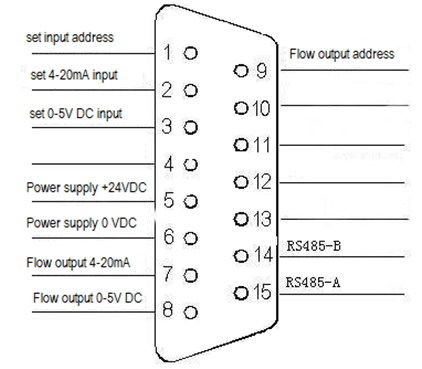

In automated manufacturing systems, SCCM flow meters often integrate with 4-20mA outputs, RS485 MODBUS, or digital displays. This allows real-time monitoring, data logging, and closed-loop control, ensuring that the gas flow remains within tight specifications.

Some advanced models allow users to set a fixed gas density to convert volumetric flow into mass flow (e.g., kg/h or lb/min). However, if the gas density changes due to pressure or temperature variations, the reading may no longer be accurate. For this reason, thermal mass flow meters that inherently measure mass flow are preferred for critical micro-flow applications.

Choosing the Right SCCM Flow Meter

When selecting an SCCM flow meter, engineers should consider several factors:

Flow Range – The instrument should cover the desired flow span (e.g., 0–10 SCCM, 0–500 SCCM) with sufficient accuracy.

Gas Type – Some meters are gas-specific, while others can be calibrated for multiple gases.

Operating Conditions – Pressure, temperature, and humidity can affect performance.

Signal Output – Choose analog (4–20mA) or digital (MODBUS, RS485, or USB) based on your control system. More information about SCCM flow meter MODBUS RUT setting.

sccm micro gas flow meter MODBUS RTU

Installation and Response Time – Micro-flow applications often demand fast response and compact size.

SCCM micro gas flow meter Wiring

Proper Use and Installation Guidelines for SCCM Gas Flow Meters

1. Installing Filters

To ensure accurate measurement and protect the flow meter, the gas must be clean and free from dust, liquids, and oil. If necessary, install a suitable filter. When connecting a liquid source bottle to the flow meter outlet, it is recommended to add a one-way valve at the outlet to prevent backflow, which could damage the flow meter.

2. Handling Corrosive Gases

Flow meter channels are constructed from corrosion-resistant materials such as SUS 316L (00Cr17Ni14Mo2), SUS 417J1 (00Cr30Mo2), and fluorine rubber. These meters can handle moderately corrosive gases and organic solvents, provided the user’s system is clean, low-leakage, and properly maintained. For special corrosive gases, all sealing materials must be adjusted accordingly. Always specify the type of gas when placing an order.

3. Installation Position

While it is recommended to install the controller on a level surface, the device is not highly sensitive to orientation and can be installed in various positions. If a zero offset occurs when the flow meter is installed at a non-horizontal angle, the zero point can be adjusted after installation.

4. Valve Sealing

The flow controller’s internal valve functions as a regulating valve, not a shut-off valve. Users should provide a separate shut-off valve on both the inlet and outlet, especially when handling corrosive gases, to ensure operational safety. After long-term use, a valve leakage rate within 2% of full scale (F.S.) is considered normal. If leakage exceeds this, maintenance is required.

5. Calibration and Gas Conversion

Flow meters are typically calibrated using nitrogen (N₂). For applications requiring calibration with other gases, this should be specified when ordering. Users can convert readings for different gases using the conversion factor provided in the appendix to ensure accurate measurement.

Appendix :Gas flow conversion factor conversion factor.

Conclusion

An SCCM flow meter plays a vital role in modern industries that rely on precise gas flow control. Whether it’s depositing thin films on semiconductors, conducting sensitive chemical research, or delivering accurate gas dosing in medical equipment, these instruments ensure stability, efficiency, and quality.

By understanding their working principles — particularly thermal mass and differential pressure types — users can select the most suitable SCCM flow meter for their process. In any application where tiny gas flows matter, an accurate SCCM flow meter is not just a tool — it’s the heartbeat of precision gas management.

Below video to show how our sccm flow meter work: