Related Products

What is sanitary positive displacement flow meter?A sanitary positive displacement flow meter is a type of flow meter designed specifically for use in sanitary or hygienic applications, such as the fo...

Hygienic Turbine Flow meter is for clean water, milk, palm oil, edible oil, vegetable oil, fish oil flow measurement ,it is used in the dairy, beverage, food processing and pharmaceutical industries.

Flow measurement is an important part of making sure that food and drinks are of high quality, that production is as efficient as possible, and that measurements are as accurate as possible. But when the medium is a thick, non-Newtonian fluid like tomato sauce (ketchup), barbecue sauce or mayonnaise, established ways of measuring flow don't always work. This article will talk about the special problems that come up when trying to measure the flow rate of ketchup and why the Coriolis mass flowmeter is the best way to solve these problems. It will also give a full explanation of how it works, its most important characteristics, and the most important things to think about when choosing one.

ketchup is not a simple fluid, and its specific physical features provide many obstacles for flow measurement:

ketchup flow measurement provide many obstacles

Fluid properties that are not Newtonian and have a high viscosity: Tomato sauce is a common non-Newtonian fluid, and its viscosity changes when the shear rate (flow rate or pumping pressure) changes. It is thick while it is still, but when you pump or stir it, it gets thinner (shear thinning). This trait makes volumetric flow meters that use constant viscosity for conversion, like turbine type and vortex street type, far less accurate.

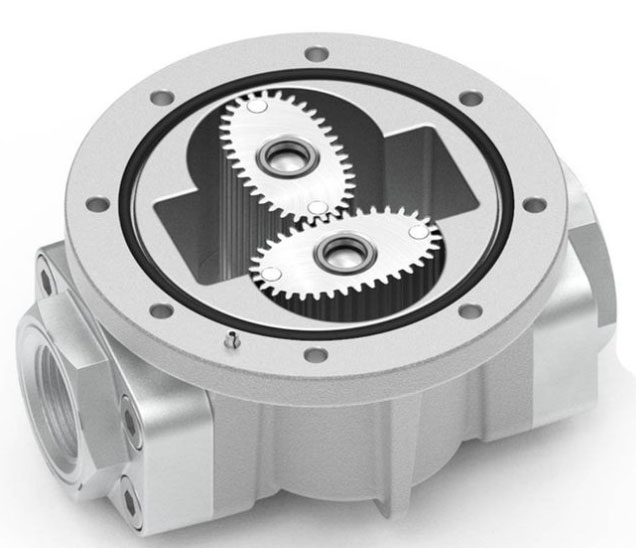

The sauce is thick and has solid particles in it (such tomato seeds and skins), which can easily produce sedimentation, obstruction, or residue (hanging on the wall) inside the flowmeter. So full bore flow meter is often needed, other flow meters like turbine flow meters have moving parts which is not suitable for ketchup flow measurement. Flow meter with moving parts inside not only makes things less clean, but it also messes up the measurement values in a big way.

Turbine flow meter has moving parts not suitable for ketchup measurement

Sensitive to shear forces: Some flow meters, like oval gear flow meters, can create large shear forces on fluids. This can change the physical properties and structure of tomato sauce, which can change the taste and quality of the final product.

Oval gear flow meters can create large shear forces on ketchup, not suitable also.

We need to measure more than one thing: Modern manufacturing processes need to know the flow rate, but they also need to be able to monitor density (for concentration management) and temperature at the same time, which traditional flow meters (such as magnetic flow meters, vortex flow meters or positive displacement flow meter) can't do.

The most important thing is: The Coriolis mass flowmeter works by directly measuring the essence.

The Coriolis mass flowmeter works based on Newton's second law of motion. Its main function is to directly measure mass flow rate instead of calculating volumetric flow rate indirectly.

The driving coil makes the measurement tubes inside the flowmeter's core sensor vibrate at high frequencies. People see the ketchup traveling through these vibrating tubes as moving particles. The Coriolis effect says that the fluid will push the measuring tube in the opposite direction, which will cause the measuring tube to twist somewhat. The magneto electric sensor on the measuring tube will be able to correctly pick up on this phase twisting distortion.

The mass flow rate is directly related to the difference in phase at both ends of the measuring tube. The more flow there is, the more the reversal.

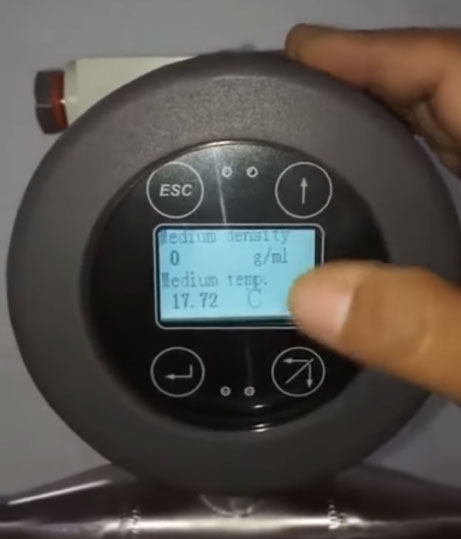

The density of the ketchup is directly related to the frequency of the measuring tube's vibrations. The vibration frequency goes down as the fluid density inside the pipe goes up. So Coriolis flow meter can also detect ketchup density information.

Ketchup density and temperature measurement by one flow sensor

A built-in RTD (resistance temperature detector) keeps an eye on the temperature in real time for temperature adjustment. This makes sure that changes in the environment don't impair the accuracy of the measurements.

This theory says that the Coriolis flowmeter can read the mass flow rate of the ketchup (in kg/h or kg/min) immediately and correctly, without having to deal with the problems that arise when measuring volume flow due to variations in viscosity, density, and temperature.

Direct mass flow measurement of ketchup

The Coriolis flowmeter has many great characteristics that help with the problems of measuring tomato sauce:

Direct mass flow measurement that isn't affected by changes in physical propertie. No matter how the viscosity of tomato sauce varies with shear force, its quality won't alter. The Coriolis flowmeter directly measures mass, which means that ketchup changes in viscosity and temperature don't affect the accuracy of the measurement. The accuracy is ± 0.1% ~ ± 0.5%.

A single straight pipe or a large-diameter bent pipe design can be used for fluids like tomato sauce. The flow path is unstoppable, so it won't get blocked. The single straight pipe design with a hygiene grade material has no obstructions, dead zones, or moving parts within, which makes the flow smooth and lowers the chance of blockage and wall hanging. It also meets the rigorous standards for SIP (in-situ sterilization) and CIP (in-situ cleaning) at the same time.

Hygiene flow meter for tomato sauce flow measurement

Multiple parameters at once make it highly versatile for tomato sauce production. It can provide you values for mass flow rate, density, and temperature all at once. This is very important when making tomato sauce, for example:

Monitoring the density of the sauce in real time to see how thick it is and how much solid it has (° Brix).

Keep an eye on the temperature curve during the sterilizing procedure.

Use quality-based batching and filling to make sure that all of the goods in a batch are the same.

No interference with the flow field, which keeps the product's properties safe: The gentle flow channel design lowers fluid shear stress, which keeps the physical qualities of tomato sauce from being damaged by too much shear and keeps the product's original flavor and texture.

To choose the right Coriolis flowmeter for tomato sauce, you need to pay attention to the following technical details:

Range and flow sensor size: The flow rate of tomato sauce is slow, so you need to choose the right mass flow sensor size to make sure that the flow rate is within the flowmeter's optimal operating range, which is usually 20% to 80% of the complete range. To stop a big opening from making the accuracy go down at low flow rates. Normally the sauce flow is smaller normal type liquid like water or fuel, because the fluidity of tomato sauce is much worse than diesel or water.

Below table we list ketchup mass flow range with corresponding mass flow sensor sizes.

|

Pipe Diameter |

Pipe Diameter |

Max Flow |

Max Flow |

Max Flow |

Pipe Diameter |

Pipe Diameter |

Max Flow |

Max Flow |

Max Flow |

|

1 |

1/32" |

0.1 |

1.67 |

220 |

40 |

1-1/2" |

22 |

367 |

48,500 |

|

2 |

5/64" |

0.7 |

11.67 |

1,543 |

50 |

2" |

33 |

550 |

72,750 |

|

3 |

1/8" |

1.5 |

25 |

3,307 |

65 |

2-1/2" |

60 |

1,000 |

132,277 |

|

6 |

1/4" |

2 |

33.33 |

4,409 |

80 |

3" |

100 |

1,667 |

220,462 |

|

10 |

3/8" |

15 |

250 |

33,069 |

100 |

4" |

160 |

2,667 |

352,739 |

|

15 |

1/2" |

30 |

500 |

66,139 |

125 |

5" |

230 |

3,833 |

507,063 |

|

20 |

3/4" |

70 |

1,167 |

154,324 |

150 |

6" |

300 |

5,000 |

661,387 |

|

25 |

1" |

130 |

2,167 |

286,602 |

- |

- |

- |

- |

- |

Output and communications of ketchup flow meter: 4-20mA analog output or frequency or pulse output: used to connect PLC or DCS systems so they can send mainstream signals.

HART/PROFIBUS-PA/Modbus RTU and other digital communication are used to send all parameters (flow rate, density, temperature, concentration) and set up and diagnose devices from a distance or other places.

Various outputs and digital communication from ketchup mass flow meter to connect PLC or DCS

Hygiene flow meter: make sure that the flow sensor fulfills hygiene design criteria in the food industries. Including whether the wet parts material is stainless steel, whether the surface smoothness of the flow sensor is very high, and whether the process connection is a sanitary connection.

Hygiene flow meter design for ketchup

Choose the right IP protection level (like IP67) and explosion-proof certification (like ATEX certified flow meter) based on where the device will be installed in the factory.

SH seires Coriolis mass flowmeter from silverinstruments.com is the best way to measure complex fluids like tomato sauce (ketchup) in the modern food industry, where efficiency, accuracy, and intelligence are key points. This is because it uses a direct mass flow measurement principle, is very versatile, and is very reliable. It is not only a tool for getting accurate measurements, but it is also a crucial asset for raising the quality of products, streamlining manufacturing processes, and lowering expenses. Buying a well-designed Coriolis flowmeter from silverinstruments.com is definitely a smart move toward better managing production.

we will contact you within 24 hours.