Diesel fuel powers everything from heavy machinery and transportation to industrial boilers and backup generators, making it a vital component of the global economy. Accurately measuring diesel flow and consumption is not only a technical necessity for any operation that uses it, but it is also essential for environmental compliance, operational effectiveness, and financial management. A critical choice that can have a big impact on dependability and profitability is choosing the appropriate diesel flow meter.

The three most popular technologies for flow measuring diesel fuel or biodiesel—Liquid Turbine flow meter ( TUF) ,Oval Gear flow meter (Positive Displacement or PD type flow meter), and Coriolis Mass Flow Meters—will all be thoroughly examined in this extensive guide. To assist you in selecting the best option for your unique flow measurement requirements, we will examine each one's operation, benefits, drawbacks, ideal uses, and installation best practices.

It is crucial to comprehend the importance of accurate fuel flow measurement before delving into the technology. With accurate data, you can:

A turbine flow meter contains a multi-bladed rotor suspended in the flow path. The rotor spins at a speed that is directly proportional to the fluid's velocity as diesel pushes against the blades as it passes through the meter. Each passing blade is detected by a magnetic pickup sensor, which produces a pulse output that is translated into a flow rate.

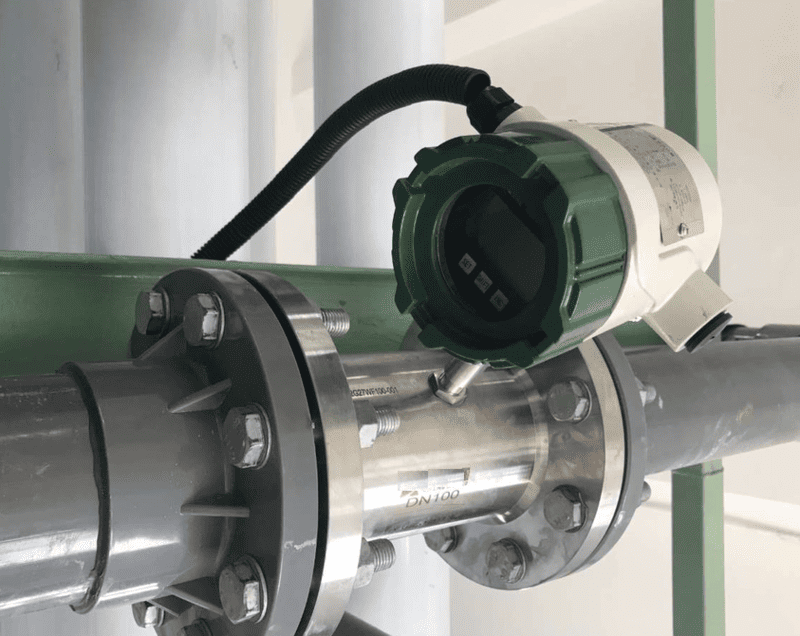

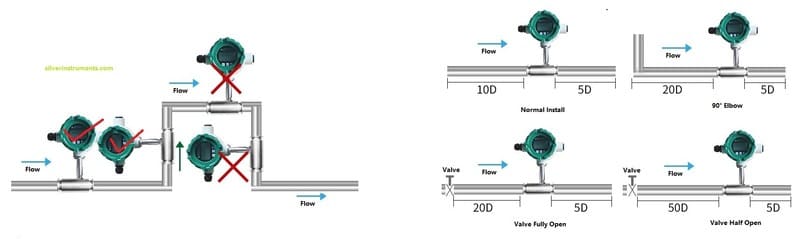

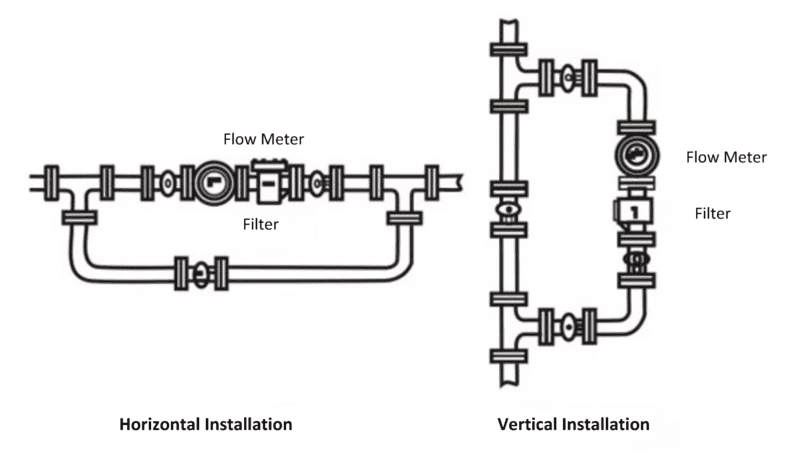

Installation done correctly is essential. A turbine meter needs a considerable amount of straight, unobstructed pipe to guarantee a consistent flow profile. It is generally advised to have a straight run of10 pipe diameters (10D) before the meter and 5 pipe diameters (5D) after it.Below table is more information about liquid turbine flow meter install.

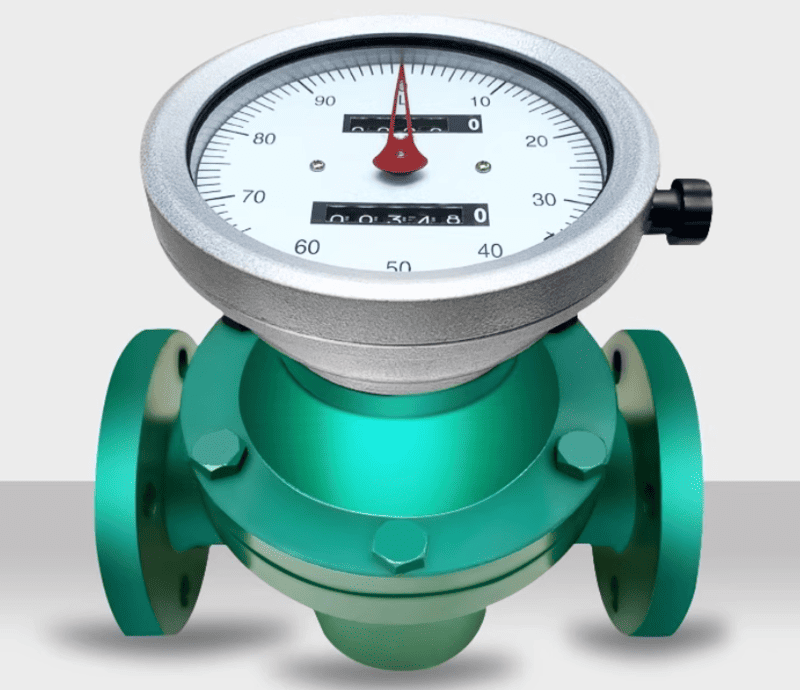

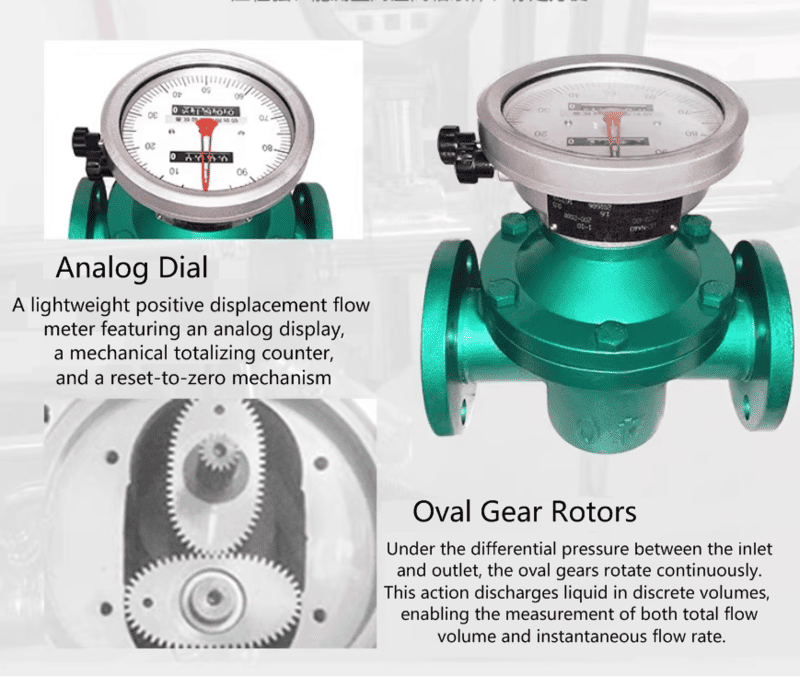

Two intricately machined, interlocking oval gears make up an oval gear meter. The gears rotate as a result of a pressure imbalance created by the diesel fuel entering the meter. A precise, known volume of fluid is trapped and passed through the meter body by the gears with each rotation. The total volume is calculated by counting these rotations using a sensor.

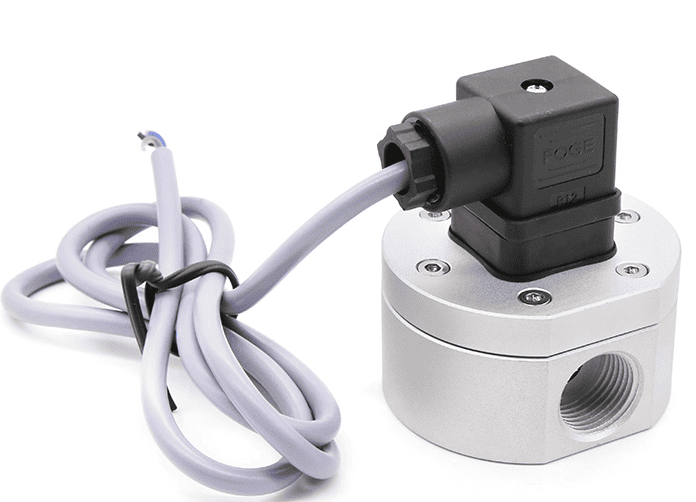

The micro oval gear flow meter is an excellent choice for applications that need precise measurement of extremely low flow rates, which are frequently expressed in milliliters per minute (ml/min). Although they are specifically designed to meet the demands of low-flow environments, these small PD meters function on the same dependable principle as their larger counterparts. They offer a very precise and economical way to measure diesel micro-flow and are perfect for applications like fuel additive injection, burner fuel consumption monitoring, and R&D test benches for small engines. Below table we list the small flow range for LC-M series flow meter from silverinstruments.com.

| Model Code | Material | Original Flow Range | Flow Range (L/h) |

| LC-M2-AL | Aluminum | 0.5-150 ml/min | 0.03 ~ 9 |

| LC-M2-SS | Stainless Steel | 0.5-150 ml/min | 0.03 ~ 9 |

| LC-M5.2-AL | Aluminum | 1-400 ml/min | 0.06 ~ 24 |

| LC-M5.2-SS | Stainless Steel | 1-400 ml/min | 0.06 ~ 24 |

| LC-M5.1-AL | Aluminum | 1~800 ml/min | 0.06 ~ 48 |

| LC-M5.1-SS | Stainless Steel | 1~800 ml/min | 0.06 ~ 48 |

| LC-M6-AL | Aluminum | 0.5~100 L/h | 0.5 ~ 100 |

| LC-M6-SS | Stainless Steel | 0.5~100 L/h | 0.5 ~ 100 |

| LC-M9-AL | Aluminum | 6~600 L/h | 6 ~ 600 |

| LC-M9-SS | Stainless Steel | 6~600 L/h | 6 ~ 600 |

| LC-M12-AL | Aluminum | 0.3~30 L/min | 18 ~ 1,800 |

| LC-M12-SS | Stainless Steel | 0.3~30 L/min | 18 ~ 1,800 |

| LC-M25-AL | Aluminum | 0.5~100 L/min | 30 ~ 6,000 |

| LC-M25-SS | Stainless Steel | 0.5~100 L/min | 30 ~ 6,000 |

The Coriolis mass flow meter is the best option for applications requiring the utmost precision and dependability.

Want to know more about best flow meter for diesel ? see below video:

Mass flow is directly measured by a Coriolis meter. It makes use of a drive coil to oscillate one or more vibrating tubes. These tubes twist as diesel passes through them due to the Coriolis effect. The minute variation in timing (phase shift) between the inlet and outlet vibrations, which is directly proportional to the mass flow rate, is picked up by sensors.

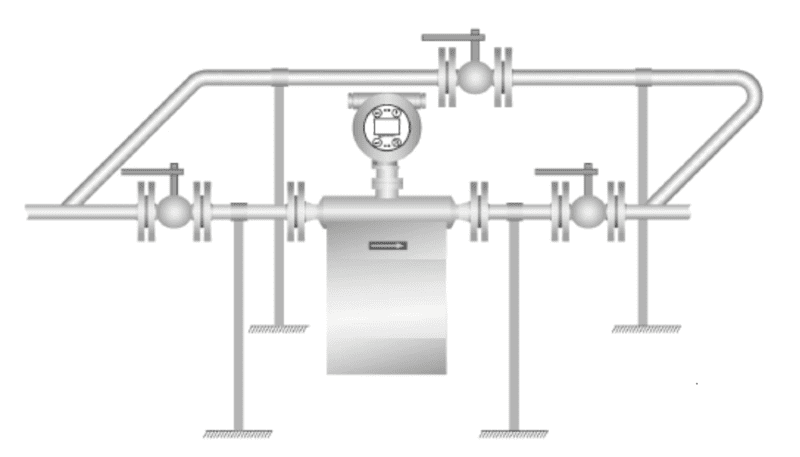

Straight pipe runs are not necessary, but in order to protect the sensitive sensor from outside plant vibrations, the meter needs to be firmly fixed to the piping. Below picture indicate the recommend install for Coriolis flow meter when measuring liquid like diesel.

| Feature | Turbine Flow Meter | Oval Gear Flow Meter | Coriolis Mass Flow Meter |

| Measurement Principle | Volumetric (Velocity) | Volumetric (Positive Displacement) | Direct Mass Flow |

| Typical Accuracy | ±0.5% | ±0.5% to ±0.2% | ±0.1 ~0.2 % |

| Viscosity Performance | Fair (sensitive to changes) | Excellent | Excellent |

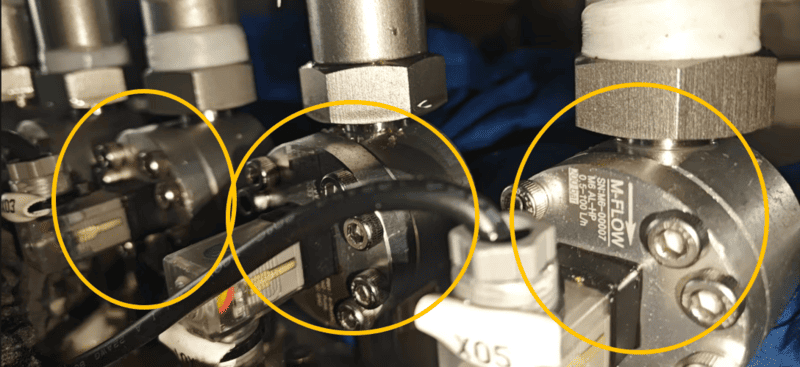

| Handles Contaminants? | No (Filter Required) | No (Filter Required) | Good (No moving parts) |

| Straight Pipe Needed? | Yes (10D/5D) | No | No |

| Initial Cost | Low to Medium | Medium | Very High |

| Ideal For | Clean, stable applications; vehicle testing. | Dispensing, refueling, boiler feed. | Custody transfer, high-value billing. |

When diesel fuel gets hot, it expands, and when it gets cold, it contracts. There may be serious mistakes if you measure volume but bill by mass or energy content. This is resolved by a Coriolis meter, which measures mass directly. Alternatively, a temperature-compensated flow rate can be computed using a flow computer in conjunction with a temperature sensor and a volumetric meter.

Make sure your meter has a batch controller to precisely dispense predetermined amounts of fuel and a totalizer to track cumulative usage for dispensing applications.

Knowing exactly what you need will help you choose the best diesel flow meter for your operation. A turbine flow meter is a good option for general-purpose clean fuel monitoring when cost is a major factor. The sturdy Oval Gear Flow Meter is the industry mainstay for accurate and dependable dispensing under a variety of circumstances. Additionally, the Coriolis Mass Flow Meter offers unparalleled performance for applications like custody transfer where the highest accuracy is non-negotiable.

Our specialty at Silver Automation Instruments is offering the appropriate flow measurement equipment for your particular problem. To assess your application and identify the best diesel flow meter solution, get in touch with our team of professionals right now. More technical information about diesel flow meter selection. Diesel flow meter selection.

Coriolis Mass Flow Meter2017/04/12Direct mass flow measurement.

Coriolis Mass Flow Meter2017/04/12Direct mass flow measurement. Oval Gear Flowmeter2017/04/12Oval Gear Flow meter is for diesel, crude oil, resin, fuel, heavy oil flow measurement. PD flow meter is with mechanical register or digital display, Inquiry Price now.VIEW

Oval Gear Flowmeter2017/04/12Oval Gear Flow meter is for diesel, crude oil, resin, fuel, heavy oil flow measurement. PD flow meter is with mechanical register or digital display, Inquiry Price now.VIEW Micro liquid flow sensor2022/03/01What is micro liquid flow sensor?Positive displacement flowmeters are used to measure the volume fluid flowing through a pipeline; it is a kind of perfect micro liquid flow sensor. At the beginning, t...VIEW

Micro liquid flow sensor2022/03/01What is micro liquid flow sensor?Positive displacement flowmeters are used to measure the volume fluid flowing through a pipeline; it is a kind of perfect micro liquid flow sensor. At the beginning, t...VIEW Micro low flow Coriolis flow meter2019/06/05Min flow 0-10 kg/hr

Micro low flow Coriolis flow meter2019/06/05Min flow 0-10 kg/hr Low flow high viscosity flow meter2019/07/13Oval gear flow meter and Coriolis mass flow meter are both suitable instruments for low flow and high viscosity flow rate measurement, the viscous fluids including: latex, crude oil, tooth paste ,resi...VIEW

Low flow high viscosity flow meter2019/07/13Oval gear flow meter and Coriolis mass flow meter are both suitable instruments for low flow and high viscosity flow rate measurement, the viscous fluids including: latex, crude oil, tooth paste ,resi...VIEW High viscosity oval gear flow meter2019/06/04High viscosity oval gear flow meter can detect fluids viscosity 2000 cp. VIEW

High viscosity oval gear flow meter2019/06/04High viscosity oval gear flow meter can detect fluids viscosity 2000 cp. VIEW