Electronic mass flow meter is used to determine the rate of flow of liquids and gasses. This is essential in different areas of plant production, efficiency and quality. For instance, since the law of conservation of material mass requires that the output mass be equal to the input mass, a mass flow meter can detect any losses in the mass as the product flows in between the input and the output. Electronic mass flow meter needs digital flow indicator to show fluids flow rate and total flow, also needs various outputs, such as current, pulse or frequency. It also needs communications, such as HART or Modbus .

There are so many industrial applications that require very small errors when determining mass flows. Therefore, high accuracy is important when selecting or buying an electronic mass flow meter for such application. A good case in point is fuel monitoring in many industrial applications where excess flow can actually alter product qualities or cause risk of fire and damage to the equipment. The same case applies to many gaseous applications.

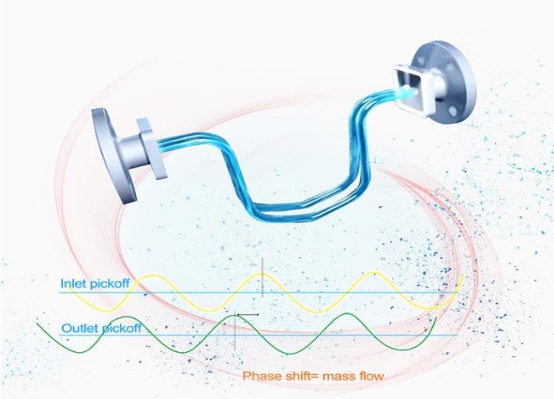

When mass flows in a tube or pipe, it

generates a force as it moves towards or away from a center of rotation. Coriolis mass flow meter is used to measure this force. Inside the flow sensor,

the force will generate a swinging as it vibrates the tube in which the mass is

flowing. The Coriolis meter will measure the amount of twist of the swing,

which is proportional to the mass flow rate of the liquid or gas passing inside

the tube.

How mass flow meter work

The digital mass flow meter can be used in applications involving water, chemicals, fuel, bitumen, resin, and gases/vapors. The changes in fluid density will not affect mass flow although care is to be taken when measuring gas/vapor flows because flow rates tend to be low. The large pressure will also drop across the flow meter and the associated piping can occur.

A thermal mass flow meter will be designed specifically for a given industrial application for gas or air mass flow measurement. These thermal dispersion flow meters do not have any moving parts, and they do not need any pressure or temperature corrections. They also retain accuracy even when used to measure flow rates over a wide range.

Digital thermal mass flow meter can handle a variety of gas, such as natural gas, biogas, N2, O2, CO2, Hydrogen, compressed air. It can detect low flow of gas and air .Electronic mass flow transmitter with 4-20mA output, pulse output for different process control. It can even equip with Hart Protocol or Modbus . Digital flow indicator can show gas flow rate and total flow vividly.

Thermal gas flow meter comes with inline flow meter and insertion type flow sensor. Insertion flow sensor is used for large pipelines which save a lot cost for large pipelines gas flow monitor.

In comparison, electronic mass flow meters

will either measure mass flow of gasses and liquids either directly or

indirectly. That may actually depend on the mechanism they employ for

measurement. Some require several types of other measurement sensors (such as industrial

temperature sensor and pressure sensor) and a flow computer to calculate mass

flow, and these are called indirect mass flow meters. For example we can use vortex flow meter, orifice plate flow meter, V-Cone flow meter, balanced flow

meter to measure gas or steam mass flow meter, we also need to equip temperature

sensor ,pressure transmitter or flow computer to calculate the gas or vapor

mass flow . Direct measurements do not require these extra devices and

equipment, for instance in the measuring of gas mass flow by using Coriolis

flow meter.

Electronic mass flowmeter is applied in varied applications including oil and gas industries, water and wastewater, power, chemical, food and beverage, and life sciences. It can be applied in applications of low to high flow rates and in challenging liquid, gas and slurry applications.

When buying a thermal mass flow meter or Coriolis flow meter, the supplier requires to understand the composition of the fluid to be measured, because the composition might affect the measurement. In such a case, proper calibration factor may be needed to determine the flow rate accurately. Although calibration exist for ever thermal mass flow meter ‘actually for every mass flow meter regardless of the mechanism it employs’s the accuracy is dependent on the actual gas mixture being measured. This may be different from the mixture used to calibrate the meter. Eletronic mass flow meter is not cheap, while Silver Automation Instruments always support customers with rugged digital flow sensor at low price.

Gas mass flow meter2020/01/31Coriolis princinple.

Gas mass flow meter2020/01/31Coriolis princinple. Liquid mass flow meter-Coriolis flow meter2020/02/19The Coriolis flow meter is widely regardedas the most accurate and highest-tech liquid mass flow meter on the markettoday. Applicable across a wide variety of industrial and municipal venues, theCorio...VIEW

Liquid mass flow meter-Coriolis flow meter2020/02/19The Coriolis flow meter is widely regardedas the most accurate and highest-tech liquid mass flow meter on the markettoday. Applicable across a wide variety of industrial and municipal venues, theCorio...VIEW Coriolis mass flow meter2019/06/12Best accuracy flow meter

Coriolis mass flow meter2019/06/12Best accuracy flow meter Thermal mass flow meter2019/06/14Low cost flow meter for gas and air

Thermal mass flow meter2019/06/14Low cost flow meter for gas and air Coriolis Mass Flow Meter2017/04/12Direct mass flow measurement.

Coriolis Mass Flow Meter2017/04/12Direct mass flow measurement. Vortex steam flow meter2020/02/01Vortex flow meters are not affected by either temperature or pressure and can provide four process measurements (mass flow, volumetric flow, pressure, temperature ) which are useful in the monitoring and control of steam in a process.VIEW

Vortex steam flow meter2020/02/01Vortex flow meters are not affected by either temperature or pressure and can provide four process measurements (mass flow, volumetric flow, pressure, temperature ) which are useful in the monitoring and control of steam in a process.VIEW Thermal mass flow meter for lab gas2019/08/08SRK-M Micro-flowrate Thermal gas mass flow meter is designed on the basis of thermal dispersion, and adopts method of constant differential temperature to measuring gas flow. It does not require exter...VIEW

Thermal mass flow meter for lab gas2019/08/08SRK-M Micro-flowrate Thermal gas mass flow meter is designed on the basis of thermal dispersion, and adopts method of constant differential temperature to measuring gas flow. It does not require exter...VIEW Insertion type thermal mass flow sensor2019/06/14Insertion gas flow sensor and easy install.

Insertion type thermal mass flow sensor2019/06/14Insertion gas flow sensor and easy install. Flanged Vortex flow meter with compensation2019/07/02STLU-BPT Series Flanged Vortex flow meter with integrated temperature sensor and pressure sensor compensation is a perfect choice for gas or steam (saturated steam and overheated steam) flow measureme...VIEW

Flanged Vortex flow meter with compensation2019/07/02STLU-BPT Series Flanged Vortex flow meter with integrated temperature sensor and pressure sensor compensation is a perfect choice for gas or steam (saturated steam and overheated steam) flow measureme...VIEW