This comprehensive guide explores the principles of intrinsic safety explosion protection, the technical features of intrinsically safe pressure transmitters, and their applications across critical industries including petrochemical, mining, and smart gas networks.

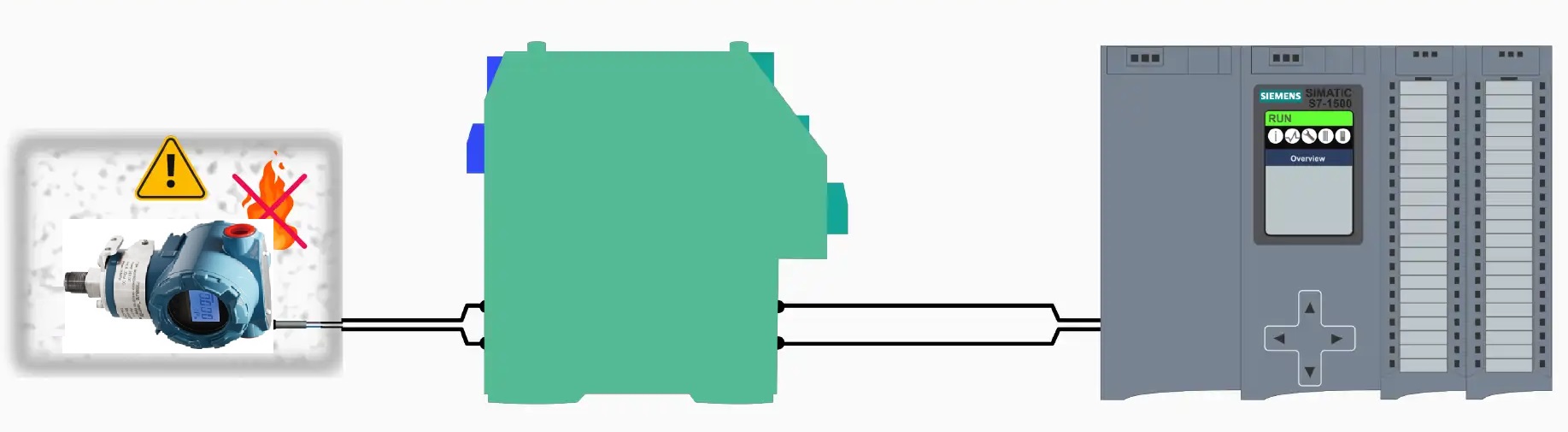

Intrinsic Safety (Ex i) is an explosion protection concept achieved by limiting electrical energy in circuits. By using safety barriers, it controls voltage, current, and power within defined limits. Even if sparks or thermal effects occur, their energy remains below the ignition threshold for explosive atmospheres.

Real-World Example: The SH308 series ATEX approved pressure transmitter with intrinsically safe design is certified Ex ia IIB T6 Ga, operating reliably from –40°C to +125°C. It withstands 100g shock and 150% overload without exceeding ignition limits—demonstrating exceptional reliability in hazardous areas.

Metal capacitive transmitters use 316 stainless steel diaphragms to convert pressure changes into standard 4–20 mA signals via bridge circuits, providing industry-standard analog output for seamless integration.

Advanced Technical Advantages:

Industrial Application: In pharmaceutical reactor pressure monitoring, these transmitters detect ultra-small 0.1 kPa pressure changes, eliminating temperature-based errors and ensuring process accuracy.

Differential pressure transmitters measure the difference between two points (ΔP = ρgΔh) to accurately calculate level, density, and flow rate in process applications.

Key Technical Features:

In storage tank pressure monitoring, intrinsically safe transmitters continuously track volatile gas pressure. Automated ventilation systems activate when pressure exceeds safety limits—dramatically cutting explosion risk.

Proven Results: After implementation at a major petrochemical plant, safety incidents dropped by 72%, generating annual cost savings of 450,000 yuan through reduced downtime and maintenance.

Underground coal mines deploy Ex ib I Mb certified transmitters to monitor ventilation pressure. When methane concentration levels rise dangerously, the 4–20 mA signal triggers immediate power supply shutdown.

Safety Impact: Post-deployment analysis shows methane-related incidents reduced by 90%, protecting miners and preventing catastrophic explosions.

Modern smart gas pipeline monitoring systems utilize differential pressure transmitters to detect pressure anomalies as small as 0.01 kPa, enabling early leak detection.

Operational Excellence: After adoption by a municipal gas utility, leak localization accuracy reached 98%, reducing annual gas loss by over 2 million m³ and improving environmental safety.

As Industry 4.0 and Industrial IoT accelerate digital transformation, intrinsically safe pressure transmitters are evolving toward intelligent integration through:

From metal capacitive precision sensors to differential pressure transmitters, intrinsically safe technology continues to redefine industrial safety standards in hazardous environments.

For procurement engineers, safety managers, and automation professionals, selecting devices with:

is essential for ensuring both operational safety and process efficiency.

As smart industrialization deepens globally, intrinsically safe pressure transmitters will remain the cornerstone of explosion-proof monitoring systems, securing the future of industrial safety in petrochemical, mining, pharmaceutical, and energy sectors.