A digital flow meter is an advanced instrument that measures the flow rate of liquids, gases, or steam in industrial piping systems using electronic sensors and digital signal processing technology. Unlike traditional mechanical flow meters with analog displays, digital flow meters convert flow measurements into electronic signals that can be displayed digitally and transmitted to control systems. They utilize various measurement principles including magmeter, ultrasonic flow meter, Coriolis effect, thermal mass transfer, rotameters with transmitters or vortex shedding—depending on the type and application.

When it comes to precision, efficiency, and long-term reliability, digital industrial flow meters stand far above their mechanical counterparts. Regardless of the medium you're monitoring, be it water, gas, oil, high-viscosity liquids, or corrosive chemicals, choosing the right digital flow meter ensures accurate readings and optimal performance in your industrial operations.

In this guide, we'll break down the most common types of digital flow meters, compare their features, and help you understand what to look for before making your purchase.

There are several types of digital flow meters used in industrial settings. Each one works on a different principle and suits specific applications. Here's a quick overview:

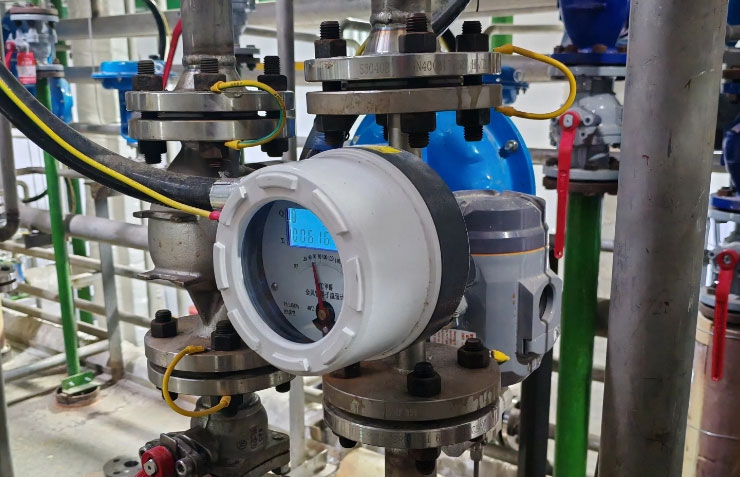

Magnetic flow meters, also referred to as electromagnetic flow meter, mag meters, measure the voltage that a liquid produces as it flows through a magnetic field to calculate the fluid flow rates. Digital magmeter can be with MODBUS, 4-20mA, pulse ,frequency, HART or PROFIBUS-DP digital communication. More information about digital magnetic flow meter profibus-dp informaiton. [ Profibus dp-digital water flow meter ]

Best for: Conductive liquids (e.g., water, acid, chemical, milk, slurry, wastewater)

Best for: Conductive liquids (e.g., water, acid, chemical, milk, slurry, wastewater)

Electromagnetic flow meters are particularly popular for digital water flow meter applications, including municipal water distribution, digital hot water flowmeter systems in industrial facilities, and digital produce water flow meter installations in agricultural operations. For smaller pipeline applications, a 2 inch digital water flow meter offers an excellent balance of accuracy and affordability.

An ultrasonic digital flow meter is a type of flow measurement device that uses ultrasonic sound waves to determine the flow rate of a fluid—usually liquids, and sometimes gases—inside a pipe. Digital ultrasonic flow meter has 4-20mA ,MODBUS RTU Communications

Best for: liquids in large pipes.

Best for: liquids in large pipes.

Unlike many other flow meters that measure volume, Coriolis meters directly measure mass flow rate of a fluid, which is especially useful when precision is critical.

The Digital Coriolis flow meter offers versatile output and communication options to suit various industrial automation needs. These include a frequency output, a standard 4-20mA analog signal with HART, and digital bus protocols such as MODBUS , with an optional Foundation Fieldbus (FF) interface also available for selection.

Best for: High-accuracy measurement of liquids and gases, it is the best accuracy flow meters.

Best for: High-accuracy measurement of liquids and gases, it is the best accuracy flow meters.

Coriolis flow meters excel in applications requiring precise mass measurement, such as digital vegetable oil flow meter installations in food processing plants and digital hydraulic oil flow meter systems in manufacturing facilities. For fuel management applications, these meters are often used alongside turbine digital diesel fuel flow meter systems to provide comprehensive monitoring solutions.

A Vortex Digital Flow Meter is a type of flow meter that measures the flow rate of liquids, gases, or steam by detecting vortices (swirling patterns) created when the fluid flows past a bluff body (a fixed obstruction in the flow path). Digital vortex type meter can have 4-20mA, pulse /frequency, HART or Modus RTU communication.

Best for: Steam, gas, and some liquids

Best for: Steam, gas, and some liquidsA Thermal Mass Flow Meter measures the actual mass flow of gases using heat transfer, providing accurate readings unaffected by temperature or pressure changes—unlike meters that measure volume or velocity. The digital thermal mass flowmeter delivers multiple output options, including a standard 4-20mA analog signal, MODBUS, and HART communication protocols for versatile connectivity.

Best for: Gas measurement (especially air, nitrogen, biogas, CO2, LPG or natural gas)

Best for: Gas measurement (especially air, nitrogen, biogas, CO2, LPG or natural gas)

Thermal mass flow meters are the preferred choice for digital natural gas flow meter installations, digital nitrogen gas flow meter applications in laboratories, and digital compressed air flow meter systems in manufacturing plants. These meters provide exceptional accuracy for digital gas flow meters across various industrial applications.

| Digital Flow Meter Type | Best Use Case | Compatible Fluids | Accuracy | Applications | Advantages | Limitations |

|---|---|---|---|---|---|---|

| Vortex Flow Meter | Steam, gas, and liquid flow measurement | Liquids, gases, steam | ±1% of reading | Steam boilers, chemical processing, HVAC systems | Handles high temperatures and pressure, durable, low maintenance | Less accurate at low flow rates |

| Electromagnetic Flow Meter (Mag Meter) | Measuring conductive liquids | Water, slurry, chemicals, wastewater | ±0.5% of reading | Water treatment, food processing, chemical plants | Highly accurate, no pressure loss, long service life | Cannot measure non-conductive fluids (e.g., oil, air, gas) |

| Ultrasonic Flow Meter | Clamp-on and inline flow monitoring | liquid | ±1% or better | Energy monitoring, water systems, pipeline flow | Non-invasive (clamp-on), no flow disruption | Accuracy may vary with pipe and fluid conditions |

| Coriolis Flow Meter | High-accuracy mass flow for liquids and gases | Liquids, gases (including high viscosity) | ±0.1% or better | Oil & gas, pharmaceutical, food and beverage | Measures mass flow directly, extremely accurate | High cost, sensitive to vibration |

| Thermal Mass Flow Meter | Low flow gas measurement | Air, nitrogen, natural gas, CO₂ | ±1-2% of reading | HVAC systems, gas leak detection, cleanrooms | Ideal for low gas flow, high sensitivity | Not suitable for liquids or dirty gases |

Now that you're familiar with the different types of digital flow meters and how they work, the next step is carefully evaluate several critical factors and align them with the appropriate flow meter type.

✅ Fluid Type

Is it a liquid or gas? Is it clean, dirty, conductive, or viscous? This will narrow down your options quickly. If the liquid is with high viscosity, like flow measurement of molasses, asphalt, fructose, and resin, you also need to tell your flow meter suppliers the fluids viscosity information. For digital liquid flow meters, understanding fluid conductivity is crucial when selecting between electromagnetic and other technologies.

✅ Flow Range

Assess the process's minimum and maximum volumetric flow rates against the flow meter's specified turndown ratio and operating range. Accurate measurement requires the flow to remain within the meter's calibrated range. For flow rates below the meter's lower detection limit, an ultra-low flow (ml/min) or micro flow meter should be selected. For flow rates exceeding the upper range, consider upsizing the flow meter or increasing the nominal pipe diameter to prevent measurement inaccuracies and maintain Reynolds number suitability.

✅ Accuracy Requirements

Do you need precise measurement or just a general idea of flow? Coriolis meters offer the highest accuracy, while vortex meters are typically "good enough" for many processes. For example, when fuel oil and LPG measurement involve trade measurement, we will choose CORIOLIS flowmeter, but for many boiler equipment, we only need a vortex flowmeter to obtain steam consumption. For custody transfer applications involving digital oil flow meter or digital diesel fuel flow meter systems, accuracy is paramount.

✅ Installation Conditions

Think about pipe size, straight run requirements, available space, and environmental conditions (temperature, pressure, vibration).

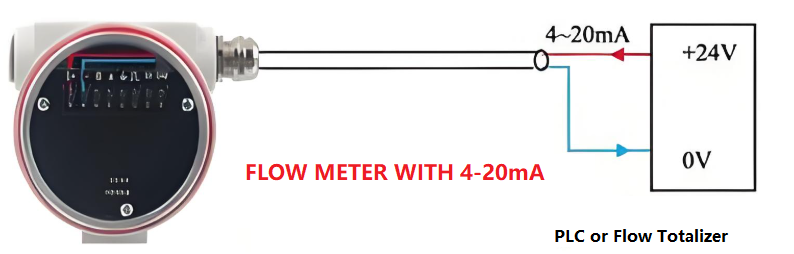

✅ Output and Connectivity

✅ Maintenance and Total Cost

Digital meters generally require less maintenance than mechanical ones, but some high-end types (like Coriolis) may involve higher upfront costs.

Digital industrial flow meters are widely used in various industries where accuracy and data-driven control are essential. Each meter type is optimized for a specific fluid condition and process environment:

Water & Wastewater Treatment: Electromagnetic flow meters (mag meters) are ideal for measuring conductive liquids such as treated water, sewage, and chemical dosing streams. For general applications, digital flow meters water solutions provide reliable performance, while water flow meter with digital display units offer convenient local monitoring. Explore various types of digital water flow meter to find the best match for your specific application.

Oil & Gas Industry: Coriolis and vortex flow meters are widely used for measuring crude oil, refined fuels, LPG, and steam flow. The versatility of these meters makes them suitable for both upstream and downstream operations.

Chemical & Petrochemical Plants: Ultrasonic and Coriolis flow meters provide non-intrusive or direct mass flow measurement for corrosive or viscous fluids. For aggressive chemical environments, a digital chemical flow meter with appropriate materials of construction is essential for long-term reliability and safety.

HVAC and Energy Management: Thermal mass flow meters accurately monitor compressed air, nitrogen, and natural gas usage for energy optimization. For compressed air systems, an digital flow meter for compressed air or air flow meter with digital output provides real-time consumption data. Facilities often prefer an air flow meter with digital display for easy on-site monitoring.

Food & Beverage Processing: Sanitary mag or Coriolis meters ensure hygienic and precise measurement of milk, syrup, or liquid ingredients.

By understanding your application and process environment, you can select a digital flow meter that provides the perfect balance of precision, durability, and ease of integration.

While the main types covered above are the most common digital flow meters, there are additional technologies worth considering for specific applications:

Digital Rotameter Flow Meters: A digital rotameter flow meter combines the visual simplicity of traditional rotameters with digital output capabilities. For air measurement applications, a digital rotameter air flow meter provides both visual confirmation and electronic signal transmission. These meters are available in various configurations, including digital metal tube rotameter models for higher pressure and temperature applications.

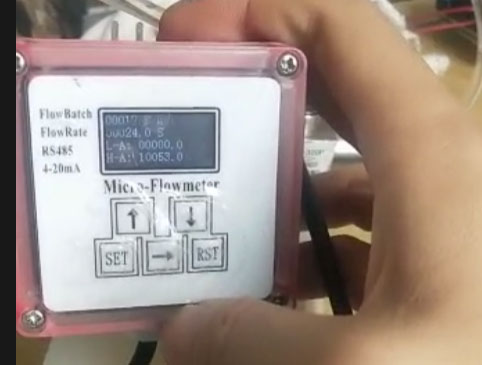

Positive Displacement Meters: For applications requiring high accuracy at low flow rates, especially with viscous fluids, consider an oval gear digital meter. These meters are also available as digital display type oval gear flow meter units, offering local readout and totalizer functions.

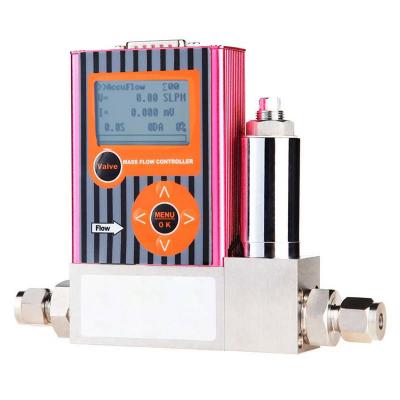

Mass Flow Controllers: For precise gas flow control in laboratory or semiconductor manufacturing environments, digital mass flow controllers provide both measurement and control capabilities in a single device. These units are essential for maintaining exact flow rates in critical processes.

Specialized Thermal Mass Meters: For advanced gas measurement applications requiring the highest accuracy, a digital thermal mass flow meter with multi-point calibration and temperature compensation offers superior performance across wide flow ranges.

Here's a quick reference guide to help you choose the right flow meter for your industry or fluid type:

| Industry / Application | Recommended Flow Meter Type | Key Advantages |

|---|---|---|

| Water & Wastewater | Electromagnetic Flow Meter | High accuracy, no moving parts |

| Chemical & Acidic Fluids | Mag Meter with PTFE/PFA lining | Corrosion-resistant |

| Oil, Fuel, LPG | Coriolis Flow Meter | Direct mass flow, high precision |

| Steam & Compressed Air | Vortex Flow Meter | Handles high temperature and pressure |

| Clean Air or Nitrogen | Thermal Mass Flow Meter | Ideal for low gas flow measurement |

| Temporary Measurement | Clamp-on Ultrasonic Flow Meter | Non-intrusive and portable |

Selecting the right meter based on your fluid characteristics and process conditions ensures stable operation and reliable readings over the long term. For comprehensive water system monitoring, a reliable water flow meter serves as the foundation of effective process control.

Modern digital flow meters offer more than just basic measurement capabilities. Many models now include advanced features that enhance functionality and user experience:

Totalizer Functions: A digital flow meter with totalizer provides cumulative flow measurement alongside instantaneous flow rate, enabling precise batch control and consumption tracking. This feature is particularly valuable in billing applications, chemical dosing, and inventory management.

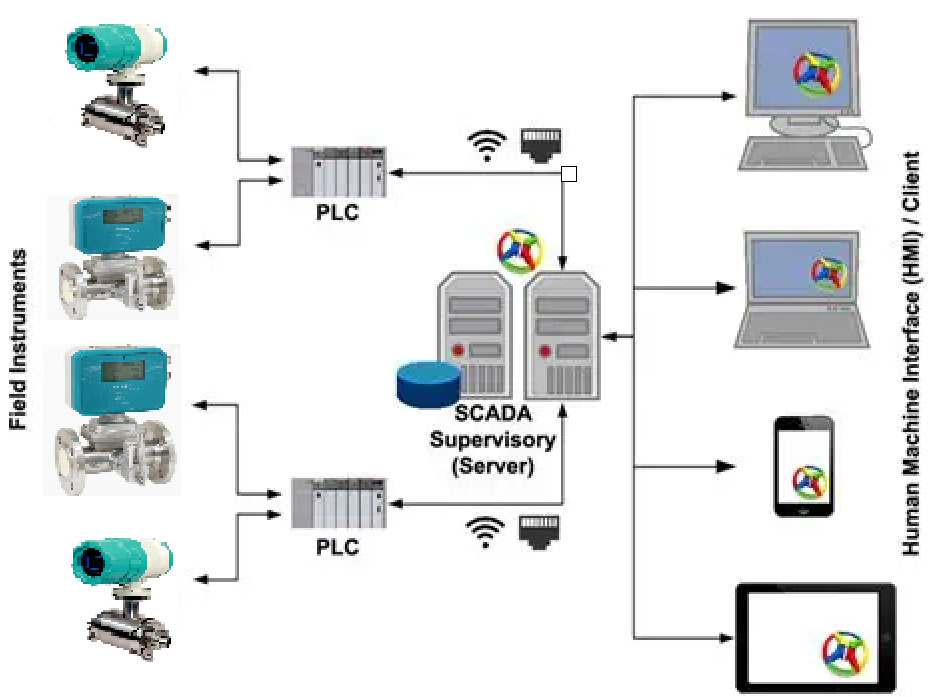

Data Logging and Communication: Many modern digital flow meters integrate with data logger and support multiple communication protocols including Modbus RTU/TCP, HART, Profibus, and others. This connectivity allows for seamless integration into Industry 4.0 environments and remote monitoring systems.

Self-Diagnostics: Premium digital flow meters include self-diagnostic features that continuously monitor sensor health, signal quality, and system performance. These flow transmitters can alert operators to potential issues before they result in measurement errors or equipment failure.

Q2: Can one digital flow meter measure both gas and liquid?

A: Generally no — different flow meter technologies are designed for specific states of matter. For example, electromagnetic and oval gear flow meters are for liquids, while vortex and thermal mass flow meters are suitable for gases and steam. If you need versatile gas measurement, check out our comprehensive guide on digital gas flowmeter technologies.

Q3: How do I determine the correct flow meter size for my system?

A: The correct size depends on your normal operating flow rate. Ideally, the flow should remain between 30% to 70% of the meter's full-scale capacity for optimal accuracy and performance.

Q4: What signal outputs can digital flow meters provide?

A: Most digital flow meters support 4-20mA, pulse/frequency, relay (alarm), and digital communication outputs (e.g. RS485/Modbus, HART, Profibus, Ethernet).

Q5: Are digital flow meters suitable for corrosive, high-temperature, or high-pressure media?

A: Yes. With proper material selection — such as PTFE-lined mag meters or Hastelloy/titanium Coriolis meters — they can handle corrosive fluids. For high-temperature steam, vortex flow meters are the preferred choice.

Q6: How often do digital flow meters require calibration or maintenance?

A: Most digital meters have stable performance and require minimal maintenance. However, it's recommended to verify calibration periodically (every 12–24 months) depending on process criticality and regulatory requirements.

With over 20 years of experience in flow measurement and process automation, Silver Automation Instruments offers a wide range of digital flow meters designed to meet diverse industrial needs. Our portfolio includes:

We provide customized configurations, including 4-20mA, Modbus, HART, Profibus-DP , pulse outputs, and various material options to suit your process conditions. Our goal is to deliver affordable, reliable, and precise flow measurement solutions backed by technical support and decades of experience.

Need help choosing the right flow meter?

Contact our experts from silverinstruments.com for a free consultation — we'll help you find the perfect match for your industrial project.

Contact Us NowChoosing the right digital industrial flow meter doesn't have to be overwhelming. Start by identifying your application needs—fluid type, flow range, and accuracy—and then match them to the most suitable meter.

Whether you're measuring water, gas, steam, or chemicals, there's a digital solution that offers better efficiency, reliability, and data-driven performance.

Liquid turbine flow meter with MODBUS2019/09/09Turbine meter MODBUS RTU RS485.

Liquid turbine flow meter with MODBUS2019/09/09Turbine meter MODBUS RTU RS485. Rotameter with 4-20ma output2020/01/30Rotameter can be variable area flow indicator, or it can be variable area rotameter with transmitter to have 4-20ma outputVIEW

Rotameter with 4-20ma output2020/01/30Rotameter can be variable area flow indicator, or it can be variable area rotameter with transmitter to have 4-20ma outputVIEW Air flow meter with 4-20mA output2019/08/08Silver Automation Instruments specializes in supplying of a wide range of inline or insertion air flow meters with analog 4-20mA output. We have many types air flow meter which can take measurement o...VIEW

Air flow meter with 4-20mA output2019/08/08Silver Automation Instruments specializes in supplying of a wide range of inline or insertion air flow meters with analog 4-20mA output. We have many types air flow meter which can take measurement o...VIEW Pulse output flow meters2021/01/27Pulsed output flow meters can be integrated into measuring / dispensing systems. Pulse flow meter can be scaled pulse output or frequency output. It can use together with computer control systems such...VIEW

Pulse output flow meters2021/01/27Pulsed output flow meters can be integrated into measuring / dispensing systems. Pulse flow meter can be scaled pulse output or frequency output. It can use together with computer control systems such...VIEW Liquid turbine flow meter with Hart Protocol2019/09/09TUF with HART and 4-20mA.

Liquid turbine flow meter with Hart Protocol2019/09/09TUF with HART and 4-20mA. Digital mass flow controllers2025/03/31Thermal dispersion principle.

Digital mass flow controllers2025/03/31Thermal dispersion principle.