Table of content

What is digital oil flow meter?

Digital oil flow meters applications

Digital oval gear flow meter for oil measurement

What kind of oil can be measure by digital oval gear flow meter?

What kind of oil cannot be measure by oval gear flow meters?

Features of digital oval gear flow meters for oil

Digital Helical gear flow meters/Bi rotor flowmeter for oil measurement

How do digital bi rotor flow meters work?

Features of electronic Bi rotor flow meters for oil measurement

Digital turbine flow meter for oil measurement

How turbine oil flow meter works ?

Features of digital oil turbine flow meter

Digital mass flow meters for oil

Specifications of digital oil flow meter

Digital oil flow meter for small flow rate

A

digital oil flow meter is a flow instrument used to measure the flow rate of oil in a system and display the readings electronically. Unlike mechanical oil flow meters, digital oil flow meters use electronic sensors and processors to provide more accurate and reliable oil flow measurements., meanwhile provide analog 4-20mA, pulse output, HART ,MODBUS or Profibus DP options for integration into broader monitoring and control systems, they are widely used in various industries where precise monitoring of oil flow is essential.

Digital oil flow meters applications

Digital oil flow meters are essential in various applications where precise measurement, monitoring, and control of oil flow are critical. Here are some key applications:

1. Industrial Processes

Oil Refineries: Digital flow meters are used to measure and control the flow of crude oil and other petroleum products during refining processes.

-

Crude Oil flow meter: crude oil as the raw material processed in refineries, we need digital crude oil flow meters to accurate count flow

-

Fuel Oil flow meter: Such as diesel, kerosene, and heating oils used in various refinery operations.

-

Lubricating Oil flow meter: lube oil is used to minimize friction in machinery within the refinery, we need lube oil flow meter .

Chemical Plants: Accurate measurement of oil flow is crucial in processes involving the blending, heating, or cooling of oil-based products.

-

Hydraulic Oil flow meter: hydraulic oil is used in hydraulic systems for machinery and equipment.

-

Heat Transfer Oil flow meter: transfer oil is used in processes requiring high-temperature fluid heating.

2. Automotive Industry

Engine Testing and Calibration: In automotive testing facilities, digital oil flow meters help ensure the precise flow of lubricants and fuel oils during engine testing and calibration.

-

Engine Oil flow meter: Lubricants with specific grades depending on the engine type (e.g., SAE 10W-30, SAE 5W-40).

-

Transmission Fluids: Essential for transmission testing and calibration.

Vehicle Fueling Systems: They are used to monitor and control fuel delivery in fuel injection systems and other vehicle fueling applications.

-

Diesel Fuel flow meter: Commonly used in commercial and heavy-duty vehicles.

-

Gasoline flow meter: Used in most light-duty vehicles.

3. Marine and Aviation

Fuel Management: Digital oil flow meters are used in ships and aircraft to monitor and manage fuel consumption accurately, ensuring efficient operation and fuel economy.

-

Marine Diesel Oil (MDO): Used in ships' engines, MDO flow meter is very important.

-

Aviation Turbine Fuel (Jet A, Jet A-1): Used in jet engines, jet fuel flow meter is needed.

-

Lubricating Oils: Specific grades for marine engines and aircraft turbines.

4. Power Generation

Turbines and Generators: In power plants, these meters are employed to measure the flow of lubricating oil to turbines and generators, ensuring optimal performance and preventing equipment damage.

-

Turbine Oils: High-quality lubricants designed for turbine engines, such as ISO VG 32 or 46, accurate digital turbine oil flow meter is necessary.

-

Transformer Oils: Used for insulation and cooling in transformers, transformer oil flow meter device is often needed.

-

Lubricating Oil flow meter : For generator bearings and other moving parts.

5. Oil and Gas Industry

Exploration and Production: During the extraction and processing of crude oil, digital flow meters are used to measure the flow of crude oil or synthetic oil through pipelines, ensuring accurate monitoring and control.

-

Crude Oil: Extracted during exploration and transported for refining, we need crude oil to be measured.

-

Synthetic Drilling Fluids: Used in drilling operations to lubricate the drill bit and transport cuttings, so synthetic oil flow meter is demanded.

Pipeline Monitoring: They are essential for leak detection, flow measurement, and control in oil transportation pipelines.

-

Crude Oil: In transportation pipelines.

-

Refined Products: Such as gasoline, diesel, and jet fuel, the fuel oil need to be measured.

6. Heating and Cooling Systems

Boilers and HVAC Systems: In systems that use oil for heating or cooling, digital flow meters are used to measure and control the flow of heating oil or chiller oil, ensuring system efficiency and preventing overheating or underperformance.

-

Heating Oil: Typically No. 2 heating oil or heavy fuel oil (HFO) used in boilers, customers often want to buy heating oil flow meter or HFO flow meter.

-

Chiller Oils: Used in cooling systems to lubricate compressor parts.

-

Biodegradable Oils: Used in environmentally sensitive applications.

7. Research and Development

Laboratory Testing: In R&D settings, digital oil flow meters are used to measure the flow of various oils in experimental setups, ensuring accurate data collection and analysis.

-

Specialty Oils: Depending on the specific tests, oils with precise chemical compositions and properties are used.

-

Silicone Oils: Often used in experiments requiring stable, inert fluids, so silicon oil flow sensors are needed.

9. Environmental Monitoring

Pollution Control: In environmental monitoring systems, digital flow meters can be used to measure the flow of oil in waste streams or emissions to ensure compliance with regulations.

-

Waste Oils: Often recycled or reclaimed oils monitored in waste streams, waste oil flow meters are often requested.

-

Emulsion Oils: Used in processes where oil and water mixtures are treated.

Each application demands oils with specific properties, such as viscosity, oil temperature, thermal stability, and chemical compatibility, tailored to the operational requirements and environmental conditions, different type digital oil flow meters with different principles are introduced here.

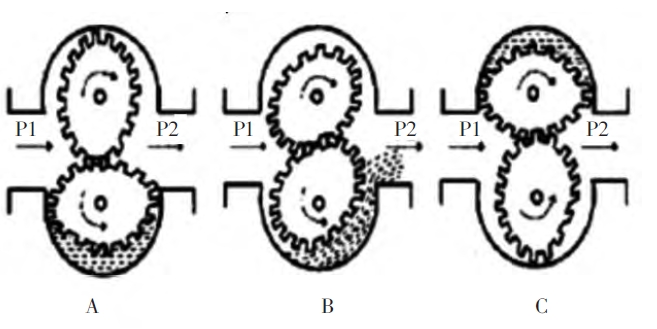

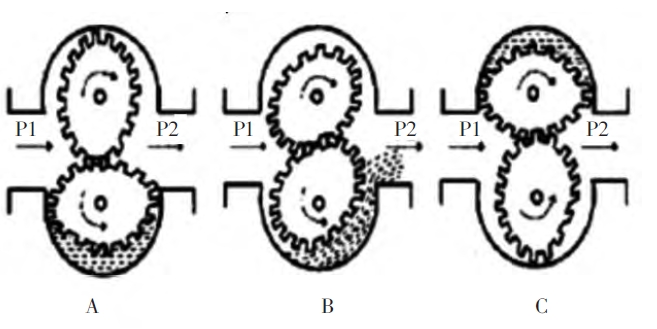

Digital oval gear flow meter for oil measurement

The oval gear flowmeter is a widely utilized volumetric flowmeter or positive displacement flow meter ( PD flow meter), known for its high accuracy, adaptability to high-viscosity oils, and robust resistance to external interferences. This type of digital oil flowmeter features two oval-shaped gears installed within the flowmeter housing that mesh together. When a differential pressure is present between the inlet and outlet of the flowmeter, the gears rotate, continuously displacing the oil contained within the "flow space" between the gears and the housing. By tracking the number of gear rotations, the volumetric flow of the oil passing through the flowmeter can be determined.

The measurement mechanisms for this PD oil flowmeter include mechanical gear types and magnetoresistive types. For the digital oval gear flow meter supplied by Silver Automation Instruments, the magnetoresistive method is employed. This involves embedding permanent magnets at both ends of the oval gears, with a magnetoresistor positioned above the meshing center of the two gears. Each full rotation of the gear is detected by the magnetoresistor as it senses the magnetic field, generating a pulse current signal. This pulse signal is directly proportional to the oil flow rate. The flowmeter's display instrument (or counter) calculates the flow rate by multiplying the number of pulses per unit time by a proportional coefficient, known as the flow compensation coefficient, specific to the flow rate. As a result, by setting the appropriate compensation coefficient, the flowmeter can deliver oil flow values within its range that meet the required accuracy standards.

What kind of oil can be measure by digital oval gear flow meter?

Digital Oval gear flow meters can measure a wide range of oils, particularly those with higher viscosities ( but should be within 2000 cp). These digital oil flow meters are ideal for lubricating oils, hydraulic oils, and fuel oils like diesel and kerosene flow measurement. These oil flow meters are also effective for measuring heavy oils such as gear oil, motor oil, and transmission fluid. Additionally, they handle flow measurement of synthetic oils used in industrial and automotive applications, maintaining accuracy even with varying fluid characteristics. Their adaptability makes them suitable for precise measurement across diverse oil types, from light to heavy-duty lubricants.

What kind of oil cannot be measure by oval gear flow meters?

Oil with solids cannot be measure by oval gear flow meters, the significant amount of suspended solids or particulate matter can cause the gears stuck and make the oil flow sensor broken. Users need to add a filter or strainer to flit the solids.

Oval gear flow meter can only measure oil viscosity within 2000 mPa.s, if you want to measure very high viscosity oil flow, you can go for Coriolis flow meters or Helical gear flow meters/Bi rotor flowmeter.

Features of digital oval gear flow meters for oil

☑ Oval gear flow meter is a precise and reliable instrument used for measuring the flow rate of viscous oil. Typically, these oil flow meters are designed with a flow range from 0.5 to 5600 liters per minute, depending on the size of the digital flow meter, the sensor sizes from DN10 to DN200 ( 8 inches digital oil flow meter).

☑ They can handle a wide range of viscosities, making them ideal for applications involving oils, chemicals, and other thick fluids.

☑ Oval gear flow meters are often constructed from materials such as stainless steel, cast iron, cast steel or aluminum, offering durability and resistance to corrosion.

☑ They provide high accuracy for oil metering, often within ±0.5% of the reading, and can operate under pressures up to 100 bar, depending on the model.

☑ These oil flow meters are suitable for both industrial and commercial applications, ensuring consistent and precise flow measurements.

Digital Helical gear flow meters/Bi rotor flowmeter for oil measurement

How do digital bi rotor flow meters work?

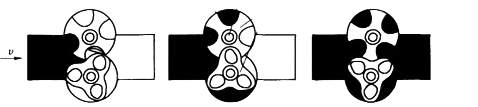

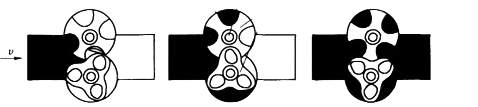

To address the challenges of vibration and noise in large flow meter systems, the American company BROOKS developed a dual rotor flow meter inspired by the principles of spiral air compressors. This innovative flow meter features a unique design that incorporates a three-lobed convex prism-shaped spiral rotor and a grooved four-lobed spiral rotor within the metering chamber. To synchronize the operation of these two distinct rotors, a pair of coaxially mounted drive gears with a gear ratio of 3:4 is positioned outside the metering chamber.

This design, known as the Bi-rotor flow meter, ensures that the rotors work in tandem, with their rotation precisely coordinated by the drive gears. The helical angles of the three-lobed and four-lobed rotors are engineered so that the total cross-sectional area swept by the rotors remains constant at any given angle. As a result, the oil flow meter operates smoothly with minimal mechanical vibration and noise, making it highly efficient and reliable for various industrial applications.

Features of electronic Bi rotor flow meters for oil measurement

The Bi rotor flowmeter is distinguished by its stable rotation, minimal mechanical vibration, and low noise levels, offering an oil measurement accuracy of up to 0.2% to 0.3%. This makes it particularly well-suited for custody transfer of petroleum products in the oil and chemical industries. As a positive displacement flowmeter, the bi rotor design provides versatile output options, including analog 4-20mA or pulse signals, similar to electronic oval gear meters.

In addition to its advanced measurement capabilities, the bi rotor flowmeter is capable of handling oils with viscosities up to 3500 cP. It accommodates pipe diameters as large as 14 inches, with the DN350 bi roto flow meter capable of managing oil flow rates up to 950 m³/h. This makes it an ideal choice for high-capacity applications requiring precise and reliable oil flow measurement.

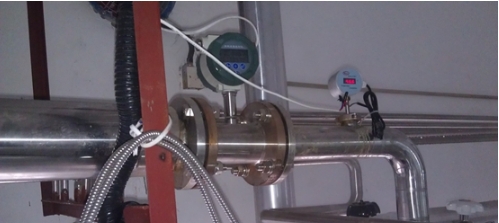

Digital turbine flow meter for oil measurement

How turbine oil flow meter works ?

Digital turbine flowmeter is a kind of velocity flow meter device that operates on the principle of conservation of angular momentum. As oil flows through the meter, it impacts the turbine blades, causing the turbine to rotate. The rotational speed of the turbine is directly proportional to the oil flow rate. This rotational speed is then measured and used to calculate the oil flow rate, with the results displayed on the turbine flow transmitter. The turbine flowmeter is capable of providing both instantaneous and cumulative oil flow readings and can convert these measurements into standard signals for remote transmission, ensuring accurate and reliable flow monitoring in various oil measurement applications.

Features of digital oil turbine flow meter

☑ Liquid turbine flowmeters are ideal for measuring clean oil, free from impurities, as debris can damage the impeller.

☑ Electronic turbine flow sensors are best suited for low-viscosity oils, with a maximum viscosity limit of 45 cP.

☑ Common applications for turbine oil flow meters include measuring diesel, kerosene, and various edible oils, such as olive oil, palm oil, and vegetable oil; however, they are not suitable for high-viscosity crude oils.

☑ These oil flowmeters feature a simple design with fewer components, making them significantly lighter than positive displacement flowmeters.

☑ They are capable of measuring the flow of high-temperature and high-pressure oils, with a maximum temperature tolerance of up to 150 degrees Celsius.

☑ The turbine flowmeter offers minimal pressure loss, a high flow capacity, and the ability to measure a wide range of oil flow rates.

☑ Additionally, they provide very fast response times, and the linear relationship between impeller speed and flow rate ensures easy signal conversion for accurate oil flow measurement.

Digital mass flow meters for oil

Coriolis flow meter is a kind of popular mass flow meters for oil flow measurement. A Coriolis flow meter measures fluid mass flow by detecting changes in vibration frequency of flow tubes, caused by the Coriolis effect as the fluid moves through them.

Specifications of digital oil flow meter

☑ Mass flowmeters can measure the flow of all oils, whether it is high viscosity oil or oil containing impurities, making up for the defects of liquid turbine flowmeters and positive displacement flowmeters.

☑ In addition, mass flowmeters are widely favored for their high precision, with the highest accuracy reaching 0.1%, making them the first choice for custody transfer flowmeters.

☑ Mass flowmeters have no moving parts and no sensor parts wear, so they are very durable.

☑ Directly measure the oil mass flow instead of correcting or calculating the mass flow.

☑ In addition to measuring the flow of oil, it can also measure oil density, volume flow and temperature.

☑ The maximum oil temperature can be measured at 350 degrees Celsius.

☑ It can be made into high-pressure oil flow meter, such as 100bar and 200 bar high-pressure oil.

☑ Digital display to show oil mass flow , has 4-20mA ,frequency output, and MODBUS communication, besides we have oil flow transmitters with PROFIBUS DP or PA option.

Digital oil flow meter for small flow rate

Digital oil flow meters designed for measuring small flow rates are crucial in applications where precision and accuracy are paramount. These

small flow meters allow for the accurate monitoring and control of oil usage in systems where even slight deviations can have significant impacts, such as in lubrication systems, fuel monitoring, and chemical dosing processes. The ability to measure small flows with high resolution helps in optimizing processes, reducing waste, and ensuring system reliability. Moreover, digital readouts provide real-time data, which is essential for maintaining the operational integrity of machinery and ensuring compliance with industry standards.

Small positive displacement flow meter

Small positive displacement flow meter

Positive displacement flow meters are commonly used for small flow measurements due to their high accuracy and reliability. These PD flow meters work by trapping a precise volume of fluid between moving components and measuring the rate at which the fluid is passed through. The advantages of volumetric flow meters include their ability to handle a wide range of viscosities and maintain accuracy regardless of fluid properties. However, they can be more prone to mechanical wear and tear due to moving parts, which can affect long-term accuracy and increase maintenance needs,also it is only limited to clean oil measurement . However this type of small flow meter have very good price and used a lot in many applications.

On the other hand, Coriolis Flow Meters operate based on the principle of mass flow, measuring the force exerted by the flow of oil on vibrating tubes. They offer high accuracy and are unaffected by changes in temperature, pressure, or fluid viscosity, making them ideal for precise small flow measurements. The primary disadvantage of Coriolis meters is their higher cost and complexity, which can make them less suitable for simple or budget-sensitive applications. Additionally, they may require more careful installation to avoid issues related to vibration and alignment.

Small Coriolis flow meter/mass flow controller2023/03/30Coriolis principle small flow meter/flow controller, Best accuracy mass flow meter for gas, liquid and steam. It can detect 40 g/h flow or even lower.VIEW

Small Coriolis flow meter/mass flow controller2023/03/30Coriolis principle small flow meter/flow controller, Best accuracy mass flow meter for gas, liquid and steam. It can detect 40 g/h flow or even lower.VIEW Coriolis Oil Flow Meter for Accurate Mass Measurement2023/11/21Coriolis Oil Flow Meter: A Precise Solution for Oil Mass MeasurementCoriolis oil flow meter, a vital tool in the realm of fluid dynamics, serves a crucial purpose in accurately measuring oil mass flow...VIEW

Coriolis Oil Flow Meter for Accurate Mass Measurement2023/11/21Coriolis Oil Flow Meter: A Precise Solution for Oil Mass MeasurementCoriolis oil flow meter, a vital tool in the realm of fluid dynamics, serves a crucial purpose in accurately measuring oil mass flow...VIEW Low flow oil flow meter2021/12/26Oval gear flow meter is a kind of inline digital low flow oil flow meter. The oil min flow it can measure is 0.03 Liter/h (0.5-150 mL/min), it is very ultra low flow oil flow meter.VIEW

Low flow oil flow meter2021/12/26Oval gear flow meter is a kind of inline digital low flow oil flow meter. The oil min flow it can measure is 0.03 Liter/h (0.5-150 mL/min), it is very ultra low flow oil flow meter.VIEW Digital Vegetable oil Flow meter2019/04/18Flow meter type: Liquid Turbine Flow meterPrinciple: The spinning rotor rotatingspeed inside the flow sensor tube is in line with the liquid passing. Flow meter sensor size available: DN4 toDN100.Pro...VIEW

Digital Vegetable oil Flow meter2019/04/18Flow meter type: Liquid Turbine Flow meterPrinciple: The spinning rotor rotatingspeed inside the flow sensor tube is in line with the liquid passing. Flow meter sensor size available: DN4 toDN100.Pro...VIEW Helical gear flow meters/Bi rotor flowmeter2019/11/08Positive displacement flow meter

Helical gear flow meters/Bi rotor flowmeter2019/11/08Positive displacement flow meter Oval gear flow meter2020/12/23Oval gear flowmeter is a kind of positive displacement flowmeter for fuel,diesel,crude oil,alcohol,lubricating oil flow measurement.VIEW

Oval gear flow meter2020/12/23Oval gear flowmeter is a kind of positive displacement flowmeter for fuel,diesel,crude oil,alcohol,lubricating oil flow measurement.VIEW