After the

Coriolis mass flowmeter was put into market, although the price was high, it replaced the some applications of

volume flowmeter, the velocity flowmeter, the differential pressure (DP flow meter) flowmeter, etc. with its irreplaceable advantages, and stably occupied the market with its excellent performance.

Why is the Coriolis flowmeter so popular and what are its advantages and disadvantages?

Let's start with the principle of coriolis.

How Coriolis flow meter work?

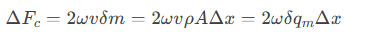

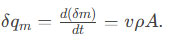

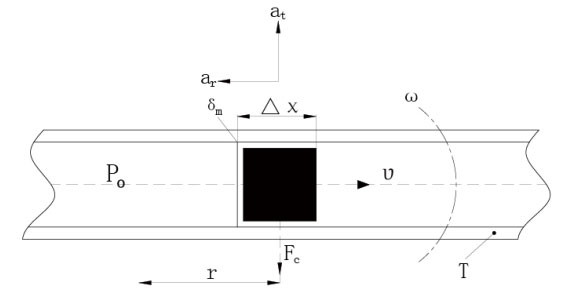

When a fluid particle moves towards or away from the center of rotation (Point P) within a rotating tube, it generates an inertial force, as illustrated in Figure 1.

Figure 1

A particle of mass δm moves at constant velocity v through a tube rotating with angular velocity ω about fixed point P. This particle experiences two acceleration components:

1. Centripetal Acceleration (αr):

Magnitude: ω2r

Direction: Toward point P.

2. Coriolis Acceleration (αt):

Magnitude: 2ωv

Direction: Perpendicular to (αr)

Per Newton's Second Law (Force = Mass × Acceleration), the Coriolis acceleration requires a corresponding force in the direction of αt , given by 2ωvδm2ωvδm. This force is applied *by the tube* onto the fluid. The *reaction force* exerted *by the fluid onto the tube is Fc=2ωvδm (the Coriolis force).

The fluid mass element is δm=ρAΔxδm=ρAΔx (where ρ = fluid density, A = tube cross-sectional area). Thus, the incremental Coriolis force is:

where the incremental mass flow rate

For a specific oscillating tube geometry with fixed vibrational characteristics, ΔFc depends solely on δqm. Therefore, measuring the Coriolis force (ΔFc) induced by the flowing fluid directly or indirectly provides a measurement of mass flow rate (qm). This is the underlying operational principle of Coriolis Mass Flow Meters.

Advantage of Coriolis meter

-

It can direct take measurement of mass flow with high measurement accuracy. the accuracy can reach to 0.1~0.5% . The Coriolis flowmeter is currently the most accurate flowmeter in the world.

The best accuracy flow meter in the world

-

It has a wide range of measurable fluids, including high viscosity fluids, ike resin , honey, glue, bitumen , polymer,molasses , lliquid-solid two-phase fluids, liquid-gas two-phase fluids containing trace gases, and medium and high pressure gases of sufficient density.

High viscosity liquid can be measured by Coriolis flow meter

-

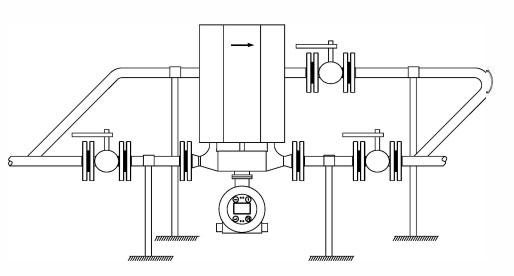

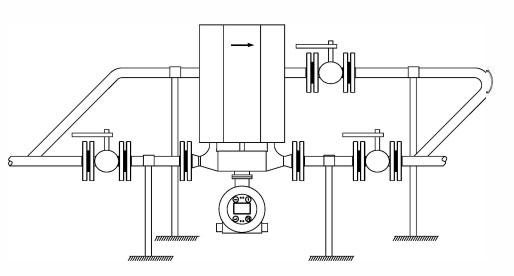

The vortex flow and non-uniform flow velocity distribution caused by the upstream and downstream pipelines have no influence on the performance of the flow sensor. Generally, it is not required straight pipe lines when installing the sensor. However, most flow meters require upstream and downstream straight pipe sections, such as electromagnetic flow meters, turbine flow meters, vortex street flow meters, etc.

No straight pipeline needed before and after mass flow meter

-

The change in fluid viscosity has no significant effect on the measured value. Coriolis flowmeter can measure high viscosity liquids, such as 500000 cp.

-

The change in fluid density has little effect on the measured value. The Coriolis flowmeter can measure high-density slurries, such as pulp, mortar, slurry, etc. Generally, the density of the slurry cannot exceed 3 g/cm³ for proper measurement of Coriolis flow meter.

Slurry can be measured if density is less than 3 g/cm³

-

There are multiple outputs, which can simultaneously output instantaneous mass flow or volume flow, fluid density, fluid temperature and other signals. It also has several digital input and output ports, and some models can realize batch control functions. It has frequency, pulse, 4-20mA current output, also it can can have MODUBS RTU(RS485) ,HART or Profibus outputs.

-

Bidirectional flow measurement

-

High pressure flow measurement that can measure high-pressure media, even media with pressures up to 14000 psi, are rare to withstand such high pressures.

For high pressure Cement slurry, pressure 40MPa, 4 "union connection

-

The Coriolis flow meter, like an electromagnetic flowmeter, can achieve bidirectional flow measurement, but before reverse measurement it requires setting parameters in the transmitter to achieve reverse flow measurement.

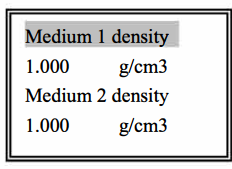

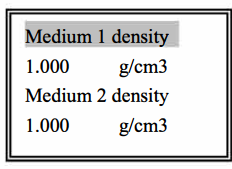

The mass flow meter's displaying percentage is the percentage of the medium 1 in the mixed medium 1 & medium 2. The percentage displaying is from Oto 100%.

The mass flow meter's displaying percentage is the percentage of the medium 1 in the mixed medium 1 & medium 2. The percentage displaying is from Oto 100%.

Disadvantage of Coriolis flow meter

-

Poor zero stability which affects the flow meter accuracy.

-

It cannot be used to measure fluids with lower density, such as low pressure or low density gas.

-

Slightly higher gas content in the liquid may cause a significant increase in measurement error.

-

It is sensitive to external vibration interference.

-

It cannot be used for larger diameters. Currently max size we can make is 10 inch Coriolis flow meter.

-

The pressure loss is large, especially when measuring a liquid with a high saturated vapor pressure, the pressure loss may cause vaporization of the liquid, and cavitation occurs.

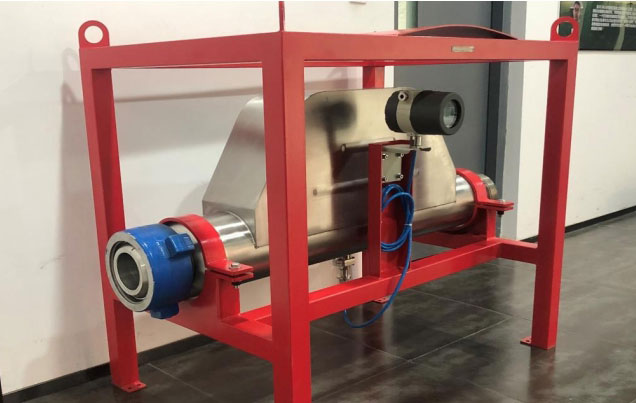

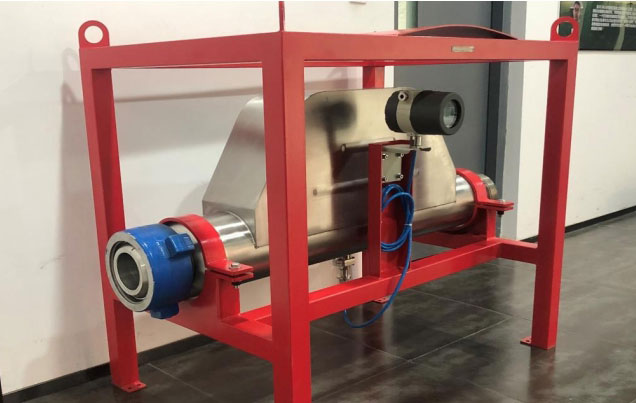

Silver Automation Instruments supply low price and stable function Coriolis flowmeters from China based flow meter manufactures.

Welcome to contact us for more information about Coriolis flow meter.

Direct mass flow measurement.

Direct mass flow measurement.

High accuracy: 0.1 %~0.2%.

Also measure density, temperature, pressure.

For all fluids measurement.

Smaller installation size.

Smaller installation size.

Max sensor size 10 inches.

Profibus PA/HART/MODBUS.

Better for high viscosity or slurry liquid.

Tri-clamp or DIN 11851 end fitting.

Tri-clamp or DIN 11851 end fitting.

316L SS wet parts.

For wine, molasses, honey, milk, yogurt, chocolate...

for food, dairy, bio-technology, pharmaceutical industry.

Coriolis principle small flow meter/flow controller.

Coriolis principle small flow meter/flow controller.

Best accuracy mass flow meter for gas, liquid and steam.

It can detect 40 g/h flow or even lower.

Low cost flow meter for gas and air.

Low cost flow meter for gas and air.

Insertion or inline type.

4-20mA & MODBUS.

air, N2, CO2, biogas, natural gas, etc.

Direct mass flow measurement.

Direct mass flow measurement. Smaller installation size.

Smaller installation size. Tri-clamp or DIN 11851 end fitting.

Tri-clamp or DIN 11851 end fitting. Coriolis principle small flow meter/flow controller.

Coriolis principle small flow meter/flow controller.