Introduction to Insertion Vortex Flow Meters

An insertion vortex flow meter is a specialized device designed to

measure the flow rate of steam, liquids or gases within a pipeline. It operates on the principle of vortex shedding, where vortices are generated by a bluff body placed in the flow path. The frequency of these vortices is directly proportional to the flow velocity, enabling accurate flow measurement.

Insertion vortex flow meters are particularly beneficial in various industrial applications, such as water measurement, large pipeline air, gas or steam measurement. They offer advantages including easy installation, minimal disruption to existing piping systems, and suitability for large-diameter pipes where traditional inline flow sensors may not be practical.

Installation Steps for Insertion Vortex Flow Meters

Installing an insertion vortex flow meter requires careful attention to detail to ensure accurate measurements and reliable operation. Follow these steps for proper installation:

Step 1

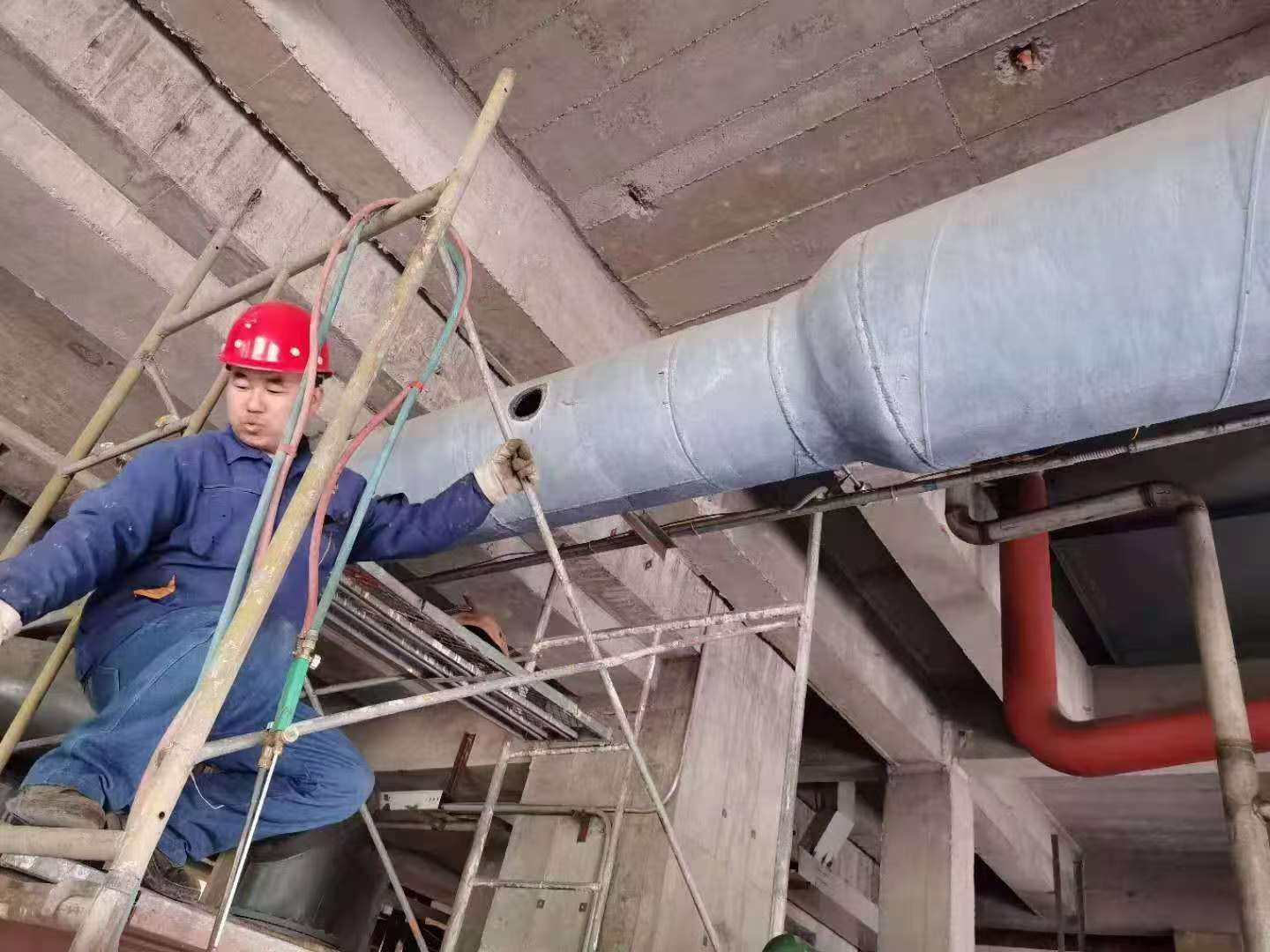

1. Prepare the Pipeline: Begin by using gas welding to create a circular hole of approximately 100 mm in diameter in the pipeline. Ensure that the edges of the hole are clean and free of any debris or burrs, as this will facilitate proper installation of the measuring head.

Prepare a 100mm circular hole

Step 2

2. Install the Flange: The flange supplied by the vortex flow meter manufacturer should have a pre-burned round hole that matches the size of the hole created in the pipeline. Secure the flange to the pipeline using appropriate fasteners to ensure a tight fit.

Step 3

3. Attach the Valve and Sensor: Next, take the ball valve and sensor assembly and install it onto the flange. Ensure that the sensor is oriented correctly for optimal flow measurement. This alignment is critical for accurate readings.

Step 4

4. Adjust Insertion Depth: Use balancing screws to adjust the insertion depth of the sensor. It is essential that the central axis of the sensor aligns perfectly with the pipeline. This alignment ensures that the flow meter accurately measures the fluid flow direction, which must correspond with the arrows marked on the device.

Step 5

5. Secure the Gland Screw: Once the insertion depth is properly set, balance the gland screw to secure the sensor in place. The lead screw’s swirl and sealing degree depend on the elasticity of the gland screw, so ensure that it is tightened appropriately without over-torquing.

Step 6

6. Final Checks and Testing: After completing the installation, perform a thorough check of each step to confirm that everything is properly secured. Gradually open the valve to allow fluid to flow through the meter, carefully monitoring for any signs of leakage. It is vital to take care not to damage the body of the flow sensor during this process. If any leaks are detected, revisit steps 5 and 6 to make necessary adjustments until the installation is leak-free.

By following these installation steps, you can ensure that your insertion vortex flow meter is set up correctly for reliable operation and accurate flow measurements. This careful approach not only enhances the longevity of the flow meter but also contributes to the overall efficiency and safety of the system it monitors. Proper installation is critical in achieving optimal performance, making it a vital step in any flow measurement project.

Silver Automation Instruments offers insertion vortex flow meter

The

insertion vortex flow meter mentioned above is offered by Silver Automation Instruments, a trusted provider of high-quality flow measurement solutions. With their advanced technology and reliable performance, these flow meters are designed to meet the demands of various industrial applications. Whether you need to measure steam, water, air, or other gases in large-diameter pipelines, Silver Automation Instruments has the right solution for you. If you require an insertion vortex flow meter or have any questions about your measurement needs, don't hesitate to contact us. Our expert team is ready to assist you in finding the perfect flow measurement solution tailored to your requirements.