Measuring molten sulfur flow accurately presents unique challenges in chemical processing, fertilizer production, and petroleum refining operations. Liquid sulfur flow measurement requires specialized instrumentation capable of handling extreme operating temperatures (130-155°C / 266-311°F), corrosive environments with H₂S and sulfuric acid, and preventing solidification risks. Coriolis Mass Flow Meters have emerged as the industry-standard solution for sulfur flow monitoring, offering direct mass measurement and exceptional reliability in demanding applications.

Molten sulfur density varies significantly with temperature fluctuations (approximately 1800 kg/m³ at operating conditions). Traditional volumetric flow meters such as vortex flow meters and electromagnetic flow meters require additional temperature compensation and density correction calculations, introducing measurement errors particularly near phase transition points.

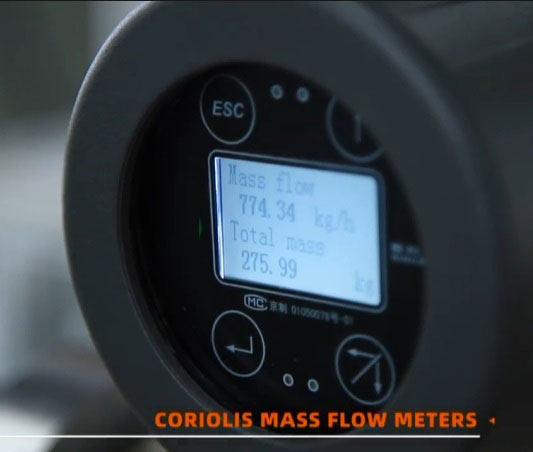

Coriolis mass flow meters eliminate these complications by measuring mass flow rate directly, independent of density variations - critical for sulfur applications where temperature control is maintained around 145°C. Performance specifications include:

Coriolis flow meters maintain measurement accuracy regardless of viscosity changes, pressure fluctuations, and temperature variations within design parameters. Molten sulfur typically exhibits low viscosity (7-10 cP, nominal 8 cP), which doesn't affect Coriolis meter performance, ensuring consistent and reliable flow measurement throughout process conditions.

Industrial-grade molten sulfur contains various impurities:

Coriolis mass flow meters demonstrate superior tolerance for minor two-phase flow conditions (solid-liquid, gas-liquid mixtures with gas content below 5%) compared to alternatives like positive displacement flow meters, which can experience jamming or mechanical failure from particulate matter. This makes Coriolis technology ideal for "dirty" or impure liquid applications.

Flow meter components in contact with molten sulfur (measuring tubes, process connections, internal surfaces) must resist corrosion from sulfur and associated impurities including H₂S and acids. Many specifications mandate NACE MR0175/ISO 15156 compliance for sulfide stress cracking (SSC) resistance in sour service environments.

316L Stainless Steel (SS316L):

The most common and cost-effective choice for molten sulfur service. Silver Instruments specifies 316L stainless steel for both housing and wetted components. This material provides:

| Code | Tube Material |

|---|---|

| M1 | 316L Stainless Steel |

| M2 | Hastelloy Alloy C-276 |

| M4 | Hastelloy Alloy B3 |

| M5 | Alloy 20 (N08020) |

| M6 | Titanium (ASTM B265) |

| M7 | Tantalum (ASTM B708) |

| M8 | C4 Steel ASTM A600T12004 |

| M9 | Copper-Nickel Alloy |

| M10 | Nickel-Based Alloy |

Hastelloy Alloys (C-276/B3):

For severe corrosive conditions with higher impurity levels, stronger acids, or extreme temperature and pressure, Hastelloy alloys provide superior corrosion resistance. Silver Automation Instruments offers these premium materials as upgrades. Select based on detailed corrosion assessment and cost-benefit analysis.

Sulfur solidification occurs at approximately 115°C (239°F). Solidification inside the flow sensor or connected piping causes:

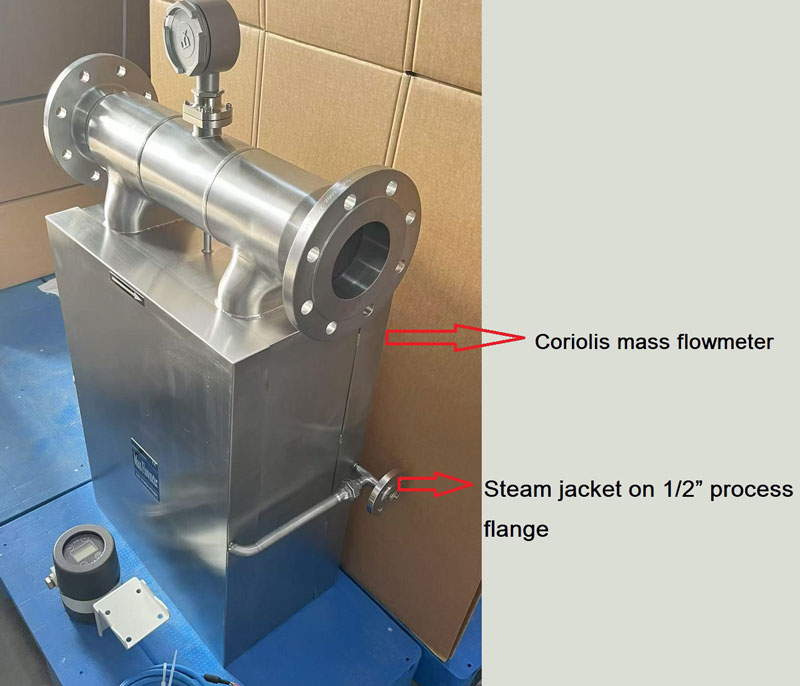

Steam jacket heating is absolutely essential for all molten sulfur flow meter installations.

Silver Instruments supplies steam or thermal oil jacket systems for process pipe sizes from 1/2" and larger:

Coriolis flow sensors can measure high-temperature process fluids up to 350°C (662°F), essential for molten sulfur applications. High-temperature flow meter designs utilize remote-mount (separated) electronics to protect sensitive transmitter components from thermal damage.

High temperature Coriolis flow meter for molten sulfur service

| Pipe Size (DN/mm) | Flow Range |

|---|---|

| DN 1.5 | 0 - 4 kg/h |

| DN 3 | 0 - 40 kg/h |

| DN 6 | 0 - 100 kg/h |

| DN 8 | 0 - 200 kg/h |

| DN 10 | 0 - 0.5 T/h |

| DN 15 | 0 - 1.0 T/h |

| DN 20 | 0 - 3.0 T/h |

| DN 25 | 0 - 10 T/h |

| DN 40 | 0 - 20 T/h |

| DN 50 | 0 - 30 T/h |

| DN 65 | 0 - 50 T/h |

| DN 80 | 0 - 100 T/h |

| DN 100 | 0 - 150 T/h |

| DN 125 | 0 - 200 T/h |

| DN 150 | 0 - 400 T/h |

| DN 200 | 0 - 500 T/h |

| Temperature Code | Temperature Range |

|---|---|

| T1 | -50°C to +150°C (-58°F to +302°F) |

| T2 | -50°C to +250°C (-58°F to +482°F) |

| T3 | -50°C to +350°C (-58°F to +662°F) |

| T4 | -200°C to +150°C (-328°F to +302°F) |

Molten sulfur flow measurement in fertilizer production (sulfuric acid plants, phosphate fertilizers) requires precise mass flow control for:

Refineries recover elemental sulfur from sour gas processing (Claus process). Accurate sulfur flow measurement ensures:

For challenging molten sulfur flow measurement applications, Coriolis Mass Flow Meters deliver the most reliable, accurate, and low-maintenance solution available. Their fundamental advantages - direct mass flow measurement, multi-variable capabilities, high accuracy, and independence from process variable changes - combined with proper material selection (NACE-compliant 316L stainless steel or superior alloys) and essential steam jacketing systems, provide engineers and operators with precise process control.

Coriolis flow meters have become the standard instrument choice for safe, efficient, long-term economical operation in sulfur processing applications. Success requires rigorous matching of process conditions to flow meter specifications during selection, proper installation following manufacturer guidelines, and routine maintenance of both the flow meter and steam heating system.

molten sulfur flow meter, liquid sulfur flow measurement, sulfur mass flow meter, Coriolis flow meter sulfur, high temperature flow meter, steam jacketed flow meter, corrosion resistant flow meter, NACE flow meter, sulfur processing instrumentation, Claus process flow measurement, fertilizer plant flow meter, refinery sulfur measurement, 316L flow meter, Hastelloy flow meter, two-phase flow meter, impurity tolerant flow meter

Oval gear flow meter with external heat jacket2019/07/09LC series oval gear flow meter with external heated measuring loops is suitable for high viscosity fluids measurement, such as asphalt, bitumen or tar flow rate measurement. VIEW

Oval gear flow meter with external heat jacket2019/07/09LC series oval gear flow meter with external heated measuring loops is suitable for high viscosity fluids measurement, such as asphalt, bitumen or tar flow rate measurement. VIEW Jacketed mass flowmeter2022/11/30What is jacketed mass flowmeter ?Jacketed mass flow meter refer to the Coriolis mass flow meter with thermal jacket, the jacket can be injected steam, hot water, heat transfer oil or other heat preser...VIEW

Jacketed mass flowmeter2022/11/30What is jacketed mass flowmeter ?Jacketed mass flow meter refer to the Coriolis mass flow meter with thermal jacket, the jacket can be injected steam, hot water, heat transfer oil or other heat preser...VIEW Rotameter flow meter with heating jacket2021/04/15What is Rotameter flow meter with heating jacket ?A heating medium such as steam, hot water or hot oil can be passed into the jacket to heat the fluids passing the variable area flow meter, or a cooli...VIEW

Rotameter flow meter with heating jacket2021/04/15What is Rotameter flow meter with heating jacket ?A heating medium such as steam, hot water or hot oil can be passed into the jacket to heat the fluids passing the variable area flow meter, or a cooli...VIEW Epoxy Resin and Hardener Flowmeters2024/05/26In industries where epoxy resin and hardener are used, precise measurement of their flows is crucial for ensuring quality and consistency in production. Coriolis flow meters are indispensable tools fo...VIEW

Epoxy Resin and Hardener Flowmeters2024/05/26In industries where epoxy resin and hardener are used, precise measurement of their flows is crucial for ensuring quality and consistency in production. Coriolis flow meters are indispensable tools fo...VIEW High viscosity oval gear flow meter2019/06/04High viscosity oval gear flow meter can detect fluids viscosity 2000 cp. VIEW

High viscosity oval gear flow meter2019/06/04High viscosity oval gear flow meter can detect fluids viscosity 2000 cp. VIEW Coriolis flow controller2024/05/14How does a Coriolis flow controller work ?A Coriolis flow controller is a sophisticated tool used in fluid management. It merges the capabilities of a Coriolis flow meter with those of a control valve...VIEW

Coriolis flow controller2024/05/14How does a Coriolis flow controller work ?A Coriolis flow controller is a sophisticated tool used in fluid management. It merges the capabilities of a Coriolis flow meter with those of a control valve...VIEW