Introduction to Electromagnetic Flowmeters

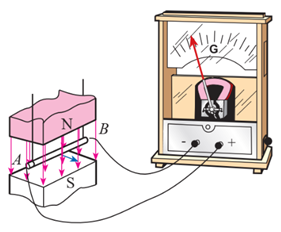

Measuring flow using the principle of electromagnetic induction is one of the most common methods among many flow measurement methods. It can measure the flow velocity and flow rate of conductive liquids in various shapes of flow channels and is an application of Faraday's law of electromagnetic induction.

Electromagnetic flowmeter is a widely used and affordable instrument.

Discovery of Electromagnetic Induction

The law of electromagnetic induction was discovered by British physicist Faraday in 1831. Faraday's law of electromagnetic induction states that when a conductor cuts magnetic lines of force in a magnetic field, an induced electromotive force perpendicular to the direction of the magnetic field and the direction of the conductor's movement will be induced at both ends of the conductor. The magnitude of the induced electromotive force is proportional to the magnetic induction intensity and the speed of movement.

First Electromagnetic Flowmeter Experiment

In 1832, Faraday placed two metal rods as electrodes on both sides of the Thames River Waterloo Bridge in a place perpendicular to the direction of the water flow and in the direction of the geomagnetic field. This was the world's first electromagnetic flowmeter experiment. However, due to electrochemical reactions, thermoelectric effects, etc., the measured signal was false, and the flow rate signal was short-circuited by the riverbed. In addition, due to the limitations of the measurement conditions at the time, he failed. Fortunately, in 1851, he saw the success of Wollsaton and others in measuring the tides of the English Channel using the electromagnetic induction method.

Faraday discovered the law of electromagnetic induction

Early Developments in Electromagnetic Flowmeters

In 1917, Smith and Spirean obtained a patent for the application of the principle of electromagnetic induction to manufacture a ship speedometer, and recommended the use of AC excitation to overcome the polarization effect of water, thus opening up the application of electromagnetic current meters in oceanography.

Advancements and Theoretical Contributions

In 1930, Williams made a copper sulfate solution flow in a non-conductive circular tube placed in a DC magnetic field. The DC voltage between the two electrodes of the circular tube was proportional to the flow rate. This device became a simple electromagnetic flowmeter. Williams used mathematical methods to analyze the influence of the flow velocity distribution in the circular tube on the measurement for the first time, and proposed the theory that the flow velocity distribution symmetrical to the central axis of the tube does not affect the measurement accuracy of the electromagnetic flowmeter. Although his analysis was mathematically wrong, the basic theory of the electromagnetic flowmeter was established from then on.

Biological Applications and Post-War Advances

Around 1932, based on Fabre's suggestion, biologists Willams and A. Colin successfully used

electromagnetic flowmeters to measure and record instantaneous arterial blood flow.

After World War II, the atomic energy industry developed rapidly, which enabled the measurement of the permanent magnet of liquid metal, and the electromagnetic flowmeter was developed and applied. However, due to the backward electronic technology at that time, its application field could not be expanded to general industry.

Industrial Adoption and Global Expansion

In 1950, the Dutch first used

slurry electromagnetic flowmeters to measure mud flow on dredgers. Later, electromagnetic flowmeters were used in general industrial production in the United States.

In 1955, Hokushin Electric and Yokogawa Electric of Japan introduced electromagnetic flowmeter products from Fischer & Porter and Foxboro of the United States respectively. After continuous digestion, absorption and improvement, their electromagnetic flowmeters soon became world advanced. Around 1955, the former Soviet Union, Britain and Germany also successfully produced electromagnetic flowmeters.

Mathematical Analysis and Technological Maturation

In the early 1960s, J.A. Shercliff completed the mathematical analysis of electromagnetic flowmeter with infinite uniform magnetic field by A. Kolin and other predecessors.

The mathematical analysis of the flow velocity under the finite length uniform magnetic field and the theory of weight function revealed the microscopic characteristics of the induced electromotive force, which made the electromagnetic flowmeter have a systematic basic theory. At the same time, under the conditions of the rapid development of the electronics industry and the continuous improvement of the degree of industrial automation, the electromagnetic flowmeter has gradually improved and matured, and developed into a flow meter with excellent performance, which has been widely used in industry.

From the late 1960s to the mid-1970s, with the in-depth study of three-dimensional weight functions, electromagnetic flowmeters with weighted distribution magnetic fields appeared, which greatly shortened the limited magnetic field length and improved the insensitivity of the measurement to flow velocity to a certain extent. At the same time, it is also conducive to simplifying the flowmeter manufacturing and reducing costs. The research results of three-dimensional weight functions have a significant guiding significance for the development of electromagnetic flowmeters during this period. Due to the rapid development of integrated circuits during this period and the higher performance requirements for flow measurement instruments put forward by the world energy crisis, a new technology of low-frequency rectangular wave excitation has emerged. Low-frequency rectangular wave excitation electromagnetic flowmeters concentrate the advantages of AC excitation flowmeters in suppressing polarization interference in DC magnetic field signals and reducing the electromagnetic induction interference signal components contained in the signals of AC magnetic field flowmeters. It improves the zero stability, sensitivity and measurement accuracy of the flowmeter, reduces power consumption, solves the problems of interchangeability, and forms a climax in the development of electromagnetic flowmeters.

Contemporary Advances and Applications

Since the 1980s, the rapid development of microelectronics and computer technology has made the manufacturing technology of electromagnetic flowmeters more mature and perfect, and its application field has been further expanded. Contemporary electromagnetic flowmeters use single-chip microcomputer technology and digital processing methods to continuously improve the measurement accuracy and performance of electromagnetic flowmeters, and can fully utilize the advantages of computers in information storage, time-sharing processing, calculation and control capabilities. Therefore, it is relatively easy to realize additional functions such as two-way measurement, empty pipe detection, multi-range automatic switching, human-computer dialogue, communication with the host computer, and self-diagnosis. The new generation of electromagnetic flowmeters with HART protocol and other field buses provide users with conditions for realizing brand-new fieldbus production control and management. Therefore, integrated, two-wire, explosion-proof, high-pressure, and communication-capable electromagnetic flowmeters are becoming more and more popular in the automatic control of industrial production processes such as chemical, petroleum, steel, and metallurgy.

Emerging Technologies and Future Directions

With the expansion of the application field, various new conductive liquid volume measurement instruments and systems using electromagnetic induction methods have emerged, such as capacitive electromagnetic flowmeters that can measure low conductivity,

Partially full pipe electromagnetic flowmeters for measuring gravity drainage, submersible electromagnetic flowmeters for open channel measurement, electromagnetic flowmeters and

insertion electromagnetic flowmeters that can measure point flow velocity in open channels and large-diameter pipes, and open channel measurement systems that consist of the electromagnetic flow velocity-water level method, etc.

Insertion electromagnetic flow meter

Development of Electromagnetic Flowmeters in China

China began to develop electromagnetic flowmeters as early as the late 1950s, and Shanghai Guanghua Instrument Factory began to provide products to the society in the early 1960s. In 1967, Shanghai Industrial Automation Instrument Research Institute, Shanghai Guanghua Instrument Factory, Kaifeng Instrument Factory, Tianjin Automation Instrument Factory No. 3, etc. participated in the national unified design of electromagnetic flowmeters organized at Shanghai Industrial Automation Instrument Research Institute. Although the time was short, everyone brainstormed and improved the understanding of electromagnetic flowmeters. In less than a year, a series of China magnetic flow meters were designed and developed. More importantly, this national unified design of electromagnetic flowmeters laid the foundation for the subsequent development of electromagnetic flowmeters in China and cultivated talents.

China's Progress and Technological Advancements

In the mid-1970s, influenced by the advanced industrial countries, the research on electromagnetic flowmeter theory in China also entered a climax. In June 1975, the famous physicists, Professor Wang Zhuxi and Professor Zhao Kaihua of Peking University were invited by many famous China magnetic flow meter factores to conduct a rigorous mathematical analysis of the electromagnetic flowmeter weight function theory and give lectures, which led to the active participation of many universities such as Huazhong University of Science and Technology, Northeastern University of Science and Technology, and Shanghai Jiaotong University in the research of electromagnetic flowmeter theory and the development of my country's weighted distributed magnetic field electromagnetic flowmeter products.

Current Status and Future Prospects

China's electromagnetic flowmeter is one of the high-tech products that have taken the road of reform earlier and more successfully, introducing foreign advanced technology and establishing joint ventures with foreign advanced enterprises. This has not only enabled the backbone electromagnetic flowmeter production enterprises to develop rapidly, but also driven the technological progress of other small and medium-sized enterprises producing electromagnetic flowmeters. At present, my country's production of electromagnetic flowmeters is basically based on low-frequency rectangular wave excitation, and has gradually entered the era of weighted magnetic field and intelligent flowmeters. The magnetic flow meter sensor size ranges from 3mm to 3000mm, and the measurement accuracy is within the range of ±0.3%R or ±1%FS. The number of china eletromagnetic flow meter manufacturers has grown from 4 in the early 1980s to about 30 at present; the output has increased from less than 1,000 sets per year to nearly 30,000 sets per year today. Whether in terms of manufacturing technology level, development capabilities or market development, the gap between China's electromagnetic flowmeters and the world's advanced level is rapidly narrowing.

China formulated the electromagnetic flowmeter industry standard in 1980. With the development and progress of technology, it was revised in 1999 and adopted the ISO international standard (ISO 9104:

The national standards GB/T 18659-2002 [Methods for evaluating the performance of electromagnetic flowmeters for measuring the flow of conductive liquids in closed pipes] and GB/T 18660-2002 [Methods for using electromagnetic flowmeters for measuring the flow of conductive liquids in closed pipes] have been promulgated. This will enable China's electromagnetic flowmeters to keep pace with international standards in the future and create conditions for the development China's electromagnetic flowmeters.

Electromagnetic Flowmeter2017/04/12Buy Quality Electromagnetic Flow meter from China manufacture in low price and fast delivery time. Get the Mag meter Price cost now from SILVER AUTOMATION INSTRUMENTS.VIEW

Electromagnetic Flowmeter2017/04/12Buy Quality Electromagnetic Flow meter from China manufacture in low price and fast delivery time. Get the Mag meter Price cost now from SILVER AUTOMATION INSTRUMENTS.VIEW Sanitary Magnetic flow meter2018/11/21SHD-SE13 Magmeter sensor is a type sanitary type flow measuring device.It can measure tap water, tomato paste, liquid egg, molasses, juice, vinegar and so on which are widely used in food-processing, beer and pharmaceutical industries.VIEW

Sanitary Magnetic flow meter2018/11/21SHD-SE13 Magmeter sensor is a type sanitary type flow measuring device.It can measure tap water, tomato paste, liquid egg, molasses, juice, vinegar and so on which are widely used in food-processing, beer and pharmaceutical industries.VIEW Slurry Magnetic Flow Meter2018/11/21SHD-SE16 Series Slurry Magnetic Flow Meter is for flow measurement in high-noise slurry applications; flow sensors for sludge, slurries and solids.VIEW

Slurry Magnetic Flow Meter2018/11/21SHD-SE16 Series Slurry Magnetic Flow Meter is for flow measurement in high-noise slurry applications; flow sensors for sludge, slurries and solids.VIEW Insertion type electromagnetic flow meter2019/06/27Insertion probe electromagnetic flow meter is suitable for pipeline size over 8 inches; it is ideal solution for large pipe size conductive liquid flow measurement ,such as waste water, portable water...VIEW

Insertion type electromagnetic flow meter2019/06/27Insertion probe electromagnetic flow meter is suitable for pipeline size over 8 inches; it is ideal solution for large pipe size conductive liquid flow measurement ,such as waste water, portable water...VIEW Battery Powered Magnetic Flow Meter2018/11/23Battery powered magmeter can measure conductive medium,such as water ,sewage and so on.The battery can work 3-6 years and size from1/2"to 40".IP68,RS485,0.25% accuracy option.VIEW

Battery Powered Magnetic Flow Meter2018/11/23Battery powered magmeter can measure conductive medium,such as water ,sewage and so on.The battery can work 3-6 years and size from1/2"to 40".IP68,RS485,0.25% accuracy option.VIEW Threaded magnetic flow meter2020/02/14Magnetic type flow meter is a flow measurement instrument made by the principle ofelectromagnetic induction, which can be used to measure the volumetric flow ofconductive liquid. Magnetic inductive fl...VIEW

Threaded magnetic flow meter2020/02/14Magnetic type flow meter is a flow measurement instrument made by the principle ofelectromagnetic induction, which can be used to measure the volumetric flow ofconductive liquid. Magnetic inductive fl...VIEW