Table of Content

What is a Mass Flow Meter and How it Work?

Mass Flow Meters: How Do They Work?

Different Types of Mass Flow Meters

Coriolis Mass Flow Meters

Thermal Mass Flow Meters

The most common applications for mass flow meters

Mass Flow Meters: What Are Their Limitations?

Potential problems with mass flow meters

The History of Mass Flow Measurement

Volume Flow and Mass Flow versus Measurement

Mass flow measurement typical applications

What is a Mass Flow Meter and How it Work?

A mass flow meter is a device used for accurately measuring the mass flow rate of a fluid in a pipe. Unlike volumetric flow rate, which measures volume per unit time, mass flow rate measures mass per unit time.

Mass flow measurement is essential for creating recipes, tracking material usage, invoicing, and transferring ownership in various industries. As the most crucial flow measurements in a processing plant, the accuracy and dependability of mass flow detection are crucial.

Mass Flow Meters: How Do They Work?

Two flow technologies,

Coriolis flow meter and

thermal mass flow meters, are utilized to measure mass flow. Coriolis meters, also known as Coriolis flow meters, utilize the Coriolis Effect to determine the mass flow rate. When a fluid passes through a pipe and experiences Coriolis acceleration due to the mechanical introduction of apparent rotation, the deflecting force created by the Coriolis inertial effect is dependent on the fluid's mass flow rate.

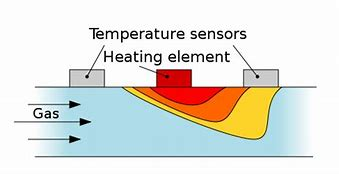

The thermal mass flow meter can directly measure the mass flow rate of liquids and gases based on the principles of heat transfer, using a heating element and temperature sensors.

Different Types of Mass Flow Meters

Coriolis Mass Flow Meters

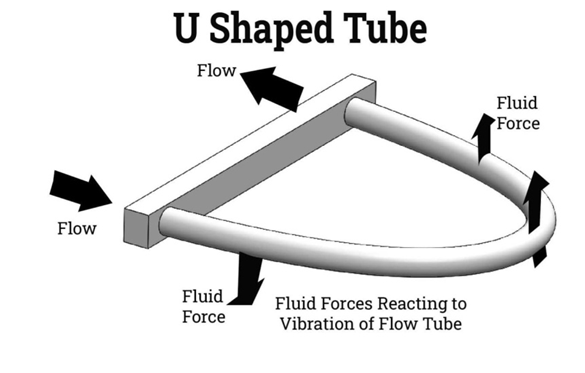

These meters called Coriolis acceleration, to the flow and measure mass flowrate by detecting the resulting angular momentum.

The Coriolis inertial effect introduces apparent rotation into a pipe that is flowing with fluid, generating a deflecting force that varies based on the mass flow rate of the fluid.

Thermal Mass Flow Meters

Thermal mass flow meters provide direct measurements of gas and liquid mass flow rates. These meters can operate by heating the fluid stream and tracking the temperature change, or by keeping a probe at a consistent temperature and measuring the necessary energy. A typical thermal mass flow meter consists of two temperature sensors and an electric heater placed between them, either inserted into the fluid stream or located externally to the pipe.

The most common applications for mass flow meters

For accurate and reliable measurement of flow in critical processes, such as chemical reactions and recipe formulations, mass flow meters are frequently used by processing plants. They assist in monitoring and controlling mass-related operations, as well as in material balance determinations and billing and custody transfer.

Explore the many applications of coriolis mass flow meters in various industries and scientific settings. These versatile meters can accurately measure mass flow, density, temperature, and viscosity of both corrosive and clean substances. Thermal mass flow meters are also commonly used for monitoring and controlling mass-related processes, such as chemical reactions.

Thermal mass flow meters are commonly used in a variety of gas-flow applications such as measuring combustion air in boilers, semiconductor gases in the chemical and petrochemical industries, and even in research and development. They are also relied upon in gas chromatography, filter and leak testing, and detecting compressible vapors and gases. One of their key benefits is their ability to accurately measure low gas flow rates and velocities, even down to under 25 ft. per minute, which cannot be achieved with other devices. When operated in constant-temperature-difference mode, thermal flow meters offer high rangeability, ranging from 10:1 to 100:1.

On the flip side, if the heat input remains unchanged, detecting minor temperature variations becomes challenging and both precision and range are affected. Under typical flow conditions, measurement inaccuracies typically fall within the 1-2% full scale range.

Mass Flow Meters: What Are Their Limitations?

The mass flow meters have a wide range of capability and precision, but their effectiveness is limited due to potential environmental factors and errors during reading, calculation, and adjustment. This may lead to decreased efficiency, potential equipment damage, and ultimately, less accuracy.

Potential problems with mass flow meters include:

-

• Coriolis mass flow meters operate best at high flow velocities, which in turn creates significant pressure drops.

-

• While the price of Coriolis meters may be higher than other flow meters, they are not able to accommodate larger sized pipes, the max size for Silver Automation Instruments Coriolis mass flow meter is 10 inches, cannot be larger.

-

• Thermal mass flow meters can be impacted by moisture condensation (especially in saturated gases) on the temperature detector. This can cause the thermometer to read inaccurately and potentially result in corrosion.

-

• Please note that thermal mass flow meters can be affected by coating or material build-up on the sensor, which can hinder heat transfer and result in a lower reading on the meter, hence regular clean is needed if the gas is dirty.

-

• Please note that thermal mass flow meters can be impacted by changes in the gas composition, specifically in regard to the specific heat. You need to configure thermal mass flow meter is gas type changes.

The History of Mass Flow Measurement

-

• Previously, mass flow was typically determined by combining the results of a volumetric flow meter and a densitometer. Density was either directly measured or calculated using data from process temperature and pressure transmitters. However, these measurements were often imprecise due to the uncertain relationship between process pressure/temperature and density. Additionally, each sensor introduced its own error and the calculations were not quick enough to capture sudden changes in flow.

-

-

• An early design of self-contained mass flow meters, utilized angular momentum to operate. A motor-driven impeller accelerated the fluid to a constant angular velocity, requiring more angular momentum for higher density. A spring-held stationary turbine was then exposed to this angular momentum downstream of the impeller.

-

-

The output torque (spring torsion) indicated the mass flow. All of these meters featured intricate mechanical designs. Originally used to measure fuel for aircraft, some are still utilized today. However, due to their intricate design and high upkeep expenses, they are gradually being replaced by more durable and low-maintenance designs.

-

-

The total mass flow of slurries can also be measured by combining an accurate level sensor with a densitometer or by using two d/p transmitters mounted on the lower part of an atmospheric tank at different elevations. In the latter case, the top d/p cell's output changes with the tank's level, while the lower one measures the material's density over a fixed elevational distance. This pressure differential determines the material's density in the tank.

Volume Flow and Mass Flow versus Measurement

Mass flow measurement and volume flow measurement are crucial methods for determining the flow in a system. These concepts are closely related, but have distinct differences. Mass flow measurement focuses on the mass of medium moving through a system in a specific timeframe, usually measured in grams per second. The flow unit we normal use is kg/hr, kg/s, t/hr, bbl/min, lb/h and so on. Coriolis flow meter and thermal mass flow meter can direct measure mass flow , however we can also get mass flow result by indirect flow measurement ,such as vortex flow meter with temperature and pressure sensors to calculate mass flow .

Volume flow measurement entails determining how much space a mass takes up within a specific duration, usually in liters per second. Both this and the other measurement gauge the speed at which something flows through a system. Furthermore, they are usually used together with other measurements to gain a comprehensive understanding of the entire system. The normal use flow unit is m3/h, L/M, GPM and so on.

Normal use volume flow meter is positive displacement flow meter, turbine flow meter, electromagnetic flow meter, ultrasonic flow meter and so on.

Mass flow measurement typical applications

|

Fuel

mass flow measurement

|

Coriolis flow meters are highly accurate and can measure fuel mass flow; They are particularly useful in applications requiring precise mass flow measurements. Coriolis flow measurement is without moving parts, which minimizes maintenance and ensures long-term reliability.

|

Coriolis flow meters for acid-alkali and chemical industries

|

Coriolis flow meters are the most accurate mass flow meters available. They come in various wetted materials such as stainless steel 316L, stainless steel 304L, Hastelloy alloy, titanium, and tantalum, making them suitable for a wide range of applications. It can be used for ammonium nitrate mass flow, sodium hypochlorite mass flow measurement, hydrochloric acid mass flow measurement and so on.

|

Coriolis flow meter for LPG/Propane mass flow measurement

|

Coriolis flow meters are ideal for measuring LPG/Propane due to their precise mass flow measurement independent of fluid properties like density and viscosity. They ensure accurate billing and custody transfer, withstand harsh conditions typical in LPG handling, and offer reliable performance with minimal maintenance, crucial for operational efficiency and safety.

|

Cryogenic Flowmeter

|

Coriolis flow meters excel in measuring cryogenic fluids due to their accurate mass flow measurement independent of fluid properties, robust design for extreme temperatures, and minimal maintenance needs, crucial for industries like liquid nitrogen, liquid oxygen, liquid argon, neon (Ne).

|

Coriolis flow controller2024/05/14How does a Coriolis flow controller work ?A Coriolis flow controller is a sophisticated tool used in fluid management. It merges the capabilities of a Coriolis flow meter with those of a control valve...VIEW

Coriolis flow controller2024/05/14How does a Coriolis flow controller work ?A Coriolis flow controller is a sophisticated tool used in fluid management. It merges the capabilities of a Coriolis flow meter with those of a control valve...VIEW Fuel Oil Mass Flow Meter2023/03/02A fuel oil mass flow meter is a type of flow meter that is specifically designed to measure the mass flow rate of fuel oil in a pipeline or process system. Coriolis flow meter is a kind of accurate fuel oil mass flow meter.VIEW

Fuel Oil Mass Flow Meter2023/03/02A fuel oil mass flow meter is a type of flow meter that is specifically designed to measure the mass flow rate of fuel oil in a pipeline or process system. Coriolis flow meter is a kind of accurate fuel oil mass flow meter.VIEW Liquid nitrogen mass flow meter2023/12/27Introduction to Cryogenic Flow Meters and Liquid Nitrogen Mass Flow MeasurementWhy is a Cryogenic Flow Meter Necessary for Liquid Nitrogen Mass Flow Measurement?The field of science that focuses on st...VIEW

Liquid nitrogen mass flow meter2023/12/27Introduction to Cryogenic Flow Meters and Liquid Nitrogen Mass Flow MeasurementWhy is a Cryogenic Flow Meter Necessary for Liquid Nitrogen Mass Flow Measurement?The field of science that focuses on st...VIEW Jacketed mass flowmeter2022/11/30What is jacketed mass flowmeter ?Jacketed mass flow meter refer to the Coriolis mass flow meter with thermal jacket, the jacket can be injected steam, hot water, heat transfer oil or other heat preser...VIEW

Jacketed mass flowmeter2022/11/30What is jacketed mass flowmeter ?Jacketed mass flow meter refer to the Coriolis mass flow meter with thermal jacket, the jacket can be injected steam, hot water, heat transfer oil or other heat preser...VIEW Insertion type thermal mass flow sensor2019/06/14Insertion gas flow sensor and easy install.

Insertion type thermal mass flow sensor2019/06/14Insertion gas flow sensor and easy install. Liquid mass flow meter-Coriolis flow meter2020/02/19The Coriolis flow meter is widely regardedas the most accurate and highest-tech liquid mass flow meter on the markettoday. Applicable across a wide variety of industrial and municipal venues, theCorio...VIEW

Liquid mass flow meter-Coriolis flow meter2020/02/19The Coriolis flow meter is widely regardedas the most accurate and highest-tech liquid mass flow meter on the markettoday. Applicable across a wide variety of industrial and municipal venues, theCorio...VIEW