Measuring flowrate of various fluids is an integral part of the oil and gas industry. There are several types of devices that are used for this purpose and the Coriolis flow meter is one of them. It has gained popularity over the past years as a tool for measuring the flowrate of liquids and gases for the manufacturers and users of oil and gas skids,also great option used as high viscosity fluids flow meter.

Coriolis flow meters incur a higher initial installment cost when compared to other types of flow meters. However, factors like its accuracy and speed of measurement, ability to capture mass readings rather than just volume, and the subsequent lower maintenance costs all work in its favor.

There are a number of advantages of the Coriolis Flow meter over other types of flow meters. Some of them are as listed below.

✅ The crucial feature of this type of flow meter is that it is the most accurate of all flow meters available.These flow meters are low maintenance because they do not have any moving parts that can cause wear and tear.✅ The mass flow meter gives accurate measurements of fluids and is not affected by the changes in temperature, pressure, speed of flow. This makes it excellent for measuring flowrate of gases which are more prone to be affected by the afore-mentioned changes. It is because of this reason that Coriolis flow meters have gained traction in the oil and gas industry.

Want to the difference between coriolis flow meter are different from other types? >>

[ Coriolis vs Magnetic flow meter ]

[ Thermal mass meter V.S. Coriolis meter ]

Coriolis flow meter is widely used in industries that require highly accurate flow measurement, such as oil and gas, petrochemicals, food and beverage, pharmaceuticals, and water treatment. It excels in applications involving high viscosity fluids, corrosive substances, and multi-parameter measurements (mass flow, density, temperature, viscosity).

Slurry flow measurement by Coriolis flow meter

Slurry flow measurement by Coriolis flow meter

Coriolis flow meter used in oil and gas industry

Coriolis flow meter used in oil and gas industry

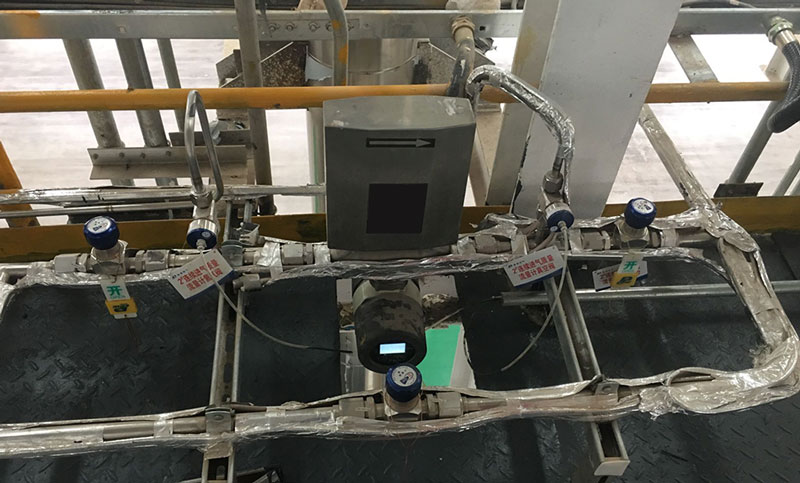

High pressure gas flow measurement

High pressure gas flow measurement

Coriolis flow meter in cementing industry

Coriolis flow meter in cementing industry

Coriolis Flow meter price Cost2018/11/16Coriolis meter is in high market price, especially for Micro motion coriolis series. Customers are always searching for the low cost coriolis mass flow meter manufacturers in China as cheaper alternativeVIEW

Coriolis Flow meter price Cost2018/11/16Coriolis meter is in high market price, especially for Micro motion coriolis series. Customers are always searching for the low cost coriolis mass flow meter manufacturers in China as cheaper alternativeVIEW Large size Coriolis mass flow meter2019/06/12Large size: 4 inch,5 inch, 6 inch, 8 inch, 10 inch,12 inch.

Large size Coriolis mass flow meter2019/06/12Large size: 4 inch,5 inch, 6 inch, 8 inch, 10 inch,12 inch. Bent tube Coriolis flow meter2019/07/22Smaller installation size.

Bent tube Coriolis flow meter2019/07/22Smaller installation size. High pressure Coriolis flow meter2019/06/11Max work on 700 bar high pressure.

High pressure Coriolis flow meter2019/06/11Max work on 700 bar high pressure. Micro low flow Coriolis flow meter2019/06/05Min flow 0-10 kg/hr

Micro low flow Coriolis flow meter2019/06/05Min flow 0-10 kg/hr Sanitary and hygienic Coriolis flow meter2019/06/12Tri-clamp or DIN 11851 end fitting

Sanitary and hygienic Coriolis flow meter2019/06/12Tri-clamp or DIN 11851 end fitting