The relationship between volume flow rate qv and mass flow rate qmis given by:

![]() (1-1)

(1-1)

or

![]() (1-2)

(1-2)

Where:

Thermal mass flowmeter, a type of direct mass flowmeter, has seen rapid development in recent years. Its basic operating principle involves using an external heat source to heat the CO2 being measured and then detecting changes in the temperature field caused by the CO2 flow to determine the CO2 mass flow. This change in the temperature field is indicated by the temperature difference between the upstream and downstream ends of the heater. The relationship between the mass flow rate qm of the fluid and the temperature difference across the heater is given by:

![]() (1-3)

(1-3)

Where:

From this equation, it can be observed that in the constant power method, the temperature difference Δt is inversely proportional to the CO2 mass flow rate qm. By measuring the temperature difference Δt, the mass flow rate qm can be determined. Conversely, in the constant temperature difference method, the heater input power P is directly proportional to the mass flow rate qm. By measuring the heater input power P, the value of qm can be obtained. The constant temperature difference method is generally preferred in practice due to its simpler relationship and easier measurement process; the co2 mass flow rate qm can be directly determined by reading the power P from a power meter, making it widely used.

The Coriolis mass flowmeter reflects the size of the mass flow rate by measuring the change of the Coriolis force. The so-called Coriolis force refers to the fact that, for an object in a reference frame rotating at a uniform angular velocity, in addition to the inertial centrifugal force, it is necessary to add another inertial force to the observer in the rotating reference frame in order to use Newton's second law to describe the state of motion of the object. This force is the Coriolis force, or Coriolis force for short. For example, if a disk is used as a rotating reference frame, and the disk rotates around the central axis at an angular velocity of, an object is assumed to move in a uniform straight line relative to the disk along the radius of the disk at a speed from the center of rotation. In addition to the inertial centrifugal force, the object is also affected by the Coriolis force. The size of the Coriolis force is determined by the angular velocity of the disk and the radial velocity of the object. Assuming that the Coriolis force is represented by f, its expression is:

(1-4)

(1-4)

In the formula:

m—the mass of the moving object

v- The speed of an object in a rotating

reference frame

`w- Angular velocity of the rotating reference frame.

As indicated by the equation, the existence of the Coriolis force depends on the simultaneous presence of radial velocity and angular velocity; if either velocity is zero, no Coriolis force will be generated.

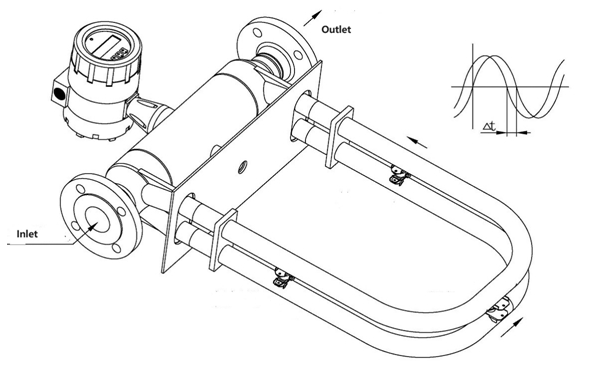

From equation (1-4), it is evident that when the angular velocity of rotation is constant, the Coriolis force fc is directly proportional to theCO2 of the mass and velocity of the object. This principle forms the fundamental theoretical basis for using the Coriolis force to measure mass flow. In flow measurement, the CO2 being measured is made to flow through a movable pipe, which rotates at a certain angular velocity, thereby achieving the simultaneous existence of flow velocity and angular velocity. This movable pipe is referred to as the flow measuring tube. The measuring tube can achieve the necessary conditions by rotating or vibrating periodically. When the fluid flows through the measuring tube, it experiences the Coriolis effect due to the periodic changes in angular velocity, albeit with a relatively simple structure.

↗ Designed for gas flow sizes ranging from micro

CO2 mass flow meter DN1.5 to DN200 (8 inches)

↗ Direct measurement of gas mass flow for

high-density gases

↗ Equipped with electronic displays, 4-20mA,

RS485, and batch control options

↗ High accuracy in measuring gas mass flow

↗ Ideal for high-pressure gas flow

applications such as monitoring CO2 or LPG gas flow

↗ Can also measure ultralow temperature CO2

mass flow

↗ Digital readings of the gas flow rate in

kilograms per second (kg/s) or kg/h, t/h ,mass flow unit

Coriolis flow meters are highly effective for measuring cryogenic CO2, especially in applications requiring precise mass flow measurement at extremely low temperatures. These meters utilize the Coriolis effect, where the fluid's mass flow rate is determined by measuring the induced Coriolis force as the CO2 flows through vibrating tubes. The key advantage of using Coriolis flow meters for cryogenic CO2 lies in their direct mass measurement capability, which remains highly accurate even at ultra-low temperatures. Additionally, they provide excellent repeatability and reliability without the need for flow straighteners or temperature compensation. This makes them ideal for applications such as cryogenic storage, transportation, and precise dosing in industrial processes where maintaining CO2 in its supercritical or liquid state is crucial.

We also offer micro mass flow meters for CO2, primarily including thermal gas micro flow meters and Coriolis flow meters.

Coriolis Mass Flow Meter2017/04/12Direct mass flow measurement.

Coriolis Mass Flow Meter2017/04/12Direct mass flow measurement. Thermal Mass Flow Meter2017/05/27Low cost gas flow meter.

Thermal Mass Flow Meter2017/05/27Low cost gas flow meter. Gas Turbine Flow Meter2017/04/12Robust Gas flow meter for natural gas,LPG,biogas flow measurement.Inquiry Gas TUF Flowmeter price with EVC directly from China manufacture.VIEW

Gas Turbine Flow Meter2017/04/12Robust Gas flow meter for natural gas,LPG,biogas flow measurement.Inquiry Gas TUF Flowmeter price with EVC directly from China manufacture.VIEW Vortex type gas flow meter2022/06/04Overview of Vortex type gas flow meter Vortex flowmeter is a fluid oscillating flow measuring instrument developed according to the principle of "Kaman vortex street". The so-called "Kamen vortex stre...VIEW

Vortex type gas flow meter2022/06/04Overview of Vortex type gas flow meter Vortex flowmeter is a fluid oscillating flow measuring instrument developed according to the principle of "Kaman vortex street". The so-called "Kamen vortex stre...VIEW Metal Tube Rotameter with Transmitter2019/05/30Rotameter with transmitter offers 4-20mA(loop powered) also digital display for different control purposes and field monitors.HH series metal tube rotameter is suitable for high temperature( 300°C,572°F...VIEW

Metal Tube Rotameter with Transmitter2019/05/30Rotameter with transmitter offers 4-20mA(loop powered) also digital display for different control purposes and field monitors.HH series metal tube rotameter is suitable for high temperature( 300°C,572°F...VIEW Low flow gas Flow Meter/Mass Flow Controller2023/07/10For gas ultra low rate as low as 2 sccm (2 ml/min), For air,biogas,natural gas, N2, O2,CO2,etc. 1%F.S accuracy and 2s response time.VIEW

Low flow gas Flow Meter/Mass Flow Controller2023/07/10For gas ultra low rate as low as 2 sccm (2 ml/min), For air,biogas,natural gas, N2, O2,CO2,etc. 1%F.S accuracy and 2s response time.VIEW