Why we need industrial temperature sensor ?

Industrial processes frequently involve the emission of a lot of heat from the equipment involved. Too much heat generating from the machine doesn’t always come with goods news.In most circumstance, It can mean a build-up of pressure, poor air circulation, and poor cooling systems that lead to overheating. Since overheating complications are challenging address at the right time when it occurs, it can result in a system breakdown.

The good news is that most equipment

manufacturers realized that an automatic temperature sensor can is a perfect

remedy for the overheating of the machinery .Therefore, machine designer’s

engineered different types of thermocouple and Resistance Temperature Detectors

that helps in detecting any slight change in temperature.

A thermocouple is an instrument used to measure temperature,It comprises of two different types of wires that form a junction at their point of union.Thewire connections within a thermocouple consist of thermo-elements,insulators,sheath,and end seals.It also has a temperature gauge as the read-out device.

Subjecting the junction to heating or cooling results to the generation of some voltage in the thermoelectric circuit, the electrical circuit wires typically have some resistance to the movement of electrons in the cable. The electrons will have to collide with external atoms and hence generate thermal energy. The thermal energy heats the wire, which the thermocouple thermometer records as temperature readings.

The output of a temperature sensor device depends solely on the type of thermocouple you decide to choose. For that effect, there are different types of thermocouple, and some of them include type Type-K, Type-J, Type-T, Type-E, Type-N, Type-S, Type-R, and Type-B.,etc

The different types of thermocouple make choosing the right kind of for a specific function quite challenging. There is a wide range of applications that thermocouple can serve. You need to have a great understanding of the structure and functionality of your choice of the thermocouple to get maximum results. Some of the vital information to look for while choosing a thermocouple includes:

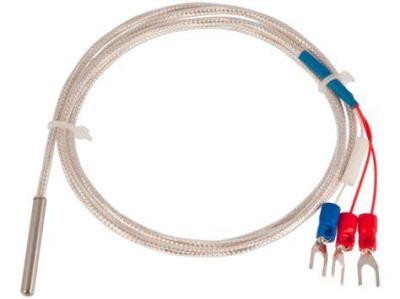

Just like thermocouple, resistant temperature detectors (RTD) also measure temperature but by determining the resistance within the electrical circuit. The resistance is directly proportional to the heat such that high resistance results in high temperatures. The building elements comprises a thin film of playinum.RTD is famous for its high accuracy and stability that makes it one of the best in the industry. Its linearity is impeccable compared to many devices. They are capable of measuring temperature as high as 1500 degrees Celsius. There are different types of RTD in the industry that performs various functions.

In RTD, the

connecting metals are nickel, copper, and platinum. The resistance-temperature-characteristic

of RTD relates to the three metals that have variations of high resistance. The

temperature of the platinum is 650 degrees Celsius. Copper is 120, and the

nickel is 300 degrees Celsius. Unlike thermocouple, it does not require a

junction.

Silver Automation Instruments offer thermocouple and RTD from China industrial temperature sensor factory at economical price and fast delivery time.

K type thermocouple2020/02/11K type thermocouple overviewK-type thermocouple is also commonly referredto as the nickel-chromium/ nickel-silicon thermocouple. Chinese thermocouple factoryoften call it WRN thermoocuple. It is a typ...VIEW

K type thermocouple2020/02/11K type thermocouple overviewK-type thermocouple is also commonly referredto as the nickel-chromium/ nickel-silicon thermocouple. Chinese thermocouple factoryoften call it WRN thermoocuple. It is a typ...VIEW S type thermocouple2020/02/11S-type (platinum-rhodium) thermocouple belongs to the class of noble metal thermocouples. The metals include platinumand rhodium with a percentage of 10% platinum. Their accuracy and stability arehigh...VIEW

S type thermocouple2020/02/11S-type (platinum-rhodium) thermocouple belongs to the class of noble metal thermocouples. The metals include platinumand rhodium with a percentage of 10% platinum. Their accuracy and stability arehigh...VIEW Spring-loaded thermocouple2020/02/11Thermocouple comes up in varyingassemblies. One of these assemblies includes spring-loaded thermocouple. As thename indicates it consists of a stainless steel spring that connects the tipsto the monit...VIEW

Spring-loaded thermocouple2020/02/11Thermocouple comes up in varyingassemblies. One of these assemblies includes spring-loaded thermocouple. As thename indicates it consists of a stainless steel spring that connects the tipsto the monit...VIEW Furnace thermocouple2020/02/11It is a device used that controls theopening and closing of the main gas line in the heating systems like gasheaters. A cylindrical or rod-shaped heat sensor is present below the pilot flamewhere it s...VIEW

Furnace thermocouple2020/02/11It is a device used that controls theopening and closing of the main gas line in the heating systems like gasheaters. A cylindrical or rod-shaped heat sensor is present below the pilot flamewhere it s...VIEW J type thermocouple2020/02/11Type J thermocouple is also a subtype ofbase metal thermocouple with iron-constantan as its constituents, is also acheap metal thermocouple. This thermocouple also has great accuracy andreliability al...VIEW

J type thermocouple2020/02/11Type J thermocouple is also a subtype ofbase metal thermocouple with iron-constantan as its constituents, is also acheap metal thermocouple. This thermocouple also has great accuracy andreliability al...VIEW Boiler thermocouples2020/02/11A boiler is a device that maintains thetemperature of water to a certain level. They serve this function by utilizingthermocouple thus called boiler thermocouples. These thermocouples are presentin bo...VIEW

Boiler thermocouples2020/02/11A boiler is a device that maintains thetemperature of water to a certain level. They serve this function by utilizingthermocouple thus called boiler thermocouples. These thermocouples are presentin bo...VIEW PT100 4 wire2020/02/11This assembly possesses a 4 wire connectionof platinum analogs. It provides the highest accuracy among all single, dualand three-wire connections. It is used widely in industries related to food,medic...VIEW

PT100 4 wire2020/02/11This assembly possesses a 4 wire connectionof platinum analogs. It provides the highest accuracy among all single, dualand three-wire connections. It is used widely in industries related to food,medic...VIEW RTD PT100 3 wires2020/02/11This is a platinum analog of RTD thatcontains 3 wire connected to each other. This design is used most commonly inindustries because of greater accuracy. The three-wire connection nullifies theerrors ...VIEW

RTD PT100 3 wires2020/02/11This is a platinum analog of RTD thatcontains 3 wire connected to each other. This design is used most commonly inindustries because of greater accuracy. The three-wire connection nullifies theerrors ...VIEW PT1002020/02/11A PT100 is an assembly of RTD that contains Platinum with a resistance value of 100 ohms at zero temp. They can measure the temperature of up to 600C. These RTD's offer higher accuracy, stability, and reliability in measurements.VIEW

PT1002020/02/11A PT100 is an assembly of RTD that contains Platinum with a resistance value of 100 ohms at zero temp. They can measure the temperature of up to 600C. These RTD's offer higher accuracy, stability, and reliability in measurements.VIEW High-temperature K type thermocouple2020/02/11This is a base metal thermocouple that canmeasure the high temperature of up to 1370C. These sensors are used mostly forovens, melting furnaces, ceramic and glass kilns and other high-temperaturefurna...VIEW

High-temperature K type thermocouple2020/02/11This is a base metal thermocouple that canmeasure the high temperature of up to 1370C. These sensors are used mostly forovens, melting furnaces, ceramic and glass kilns and other high-temperaturefurna...VIEW