Each cycle of the moving element displaces

a volume . If the

moving component completes

cycles , the total volume of fuel

that has passed through the flowmeter is calculated by:

The mechanical movement of the component is

transmitted through a gear mechanism to an indicator, which then moves the

pointer on a dial. This dial displays the total volume of fuel that has passed

through the flowmeter.

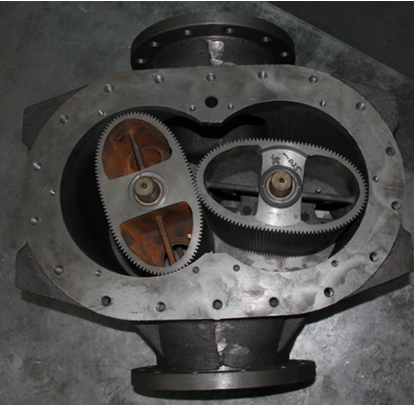

Oval gear flow meter is a kind of positive

displacement flowmeter which is a widely used mechanical fuel flowmeter that measures fuel oil flow by repeatedly capturing a fixed volume. Known for its

one-directional flow, it is referred to as a "positive displacement

flowmeter" in various regions.

It boasts a long history and broad

applicability, with notable advantages:

1. High Measurement Accuracy: Achieves a

relative error of ±0.1% to ±0.5%. oval gear flow meter accuracy remains

unaffected by fuel oil type, viscosity, density, Reynolds number, or the length

of the upstream and downstream straight pipe sections.

2. Wide Measurement Range: Oval gear flow

meter is capable of achieving an accuracy of 0.5 at a range of 10. It provides

precise cumulative fuel oil measurements, making it suitable for material

measurement applications.

3. Effective at Low Reynolds Numbers:

Measures high-viscosity and low-flow-rate fuel with high precision, even in low

Reynolds number conditions, can be used as high viscosity fuel flow meter.

4. Short Straight Pipe Section when install

mechanical fuel flow emter: Functions effectively on-site with minimal

requirements for upstream and downstream straight pipe sections.

Disadvantages of mechancial fuel flow meter

However, there are several disadvantages

associated with positive displacement type fuel flowmeters that must be

considered:

1. Bulk and Complexity: For the same flow

capacity, positive displacement flowmeters tend to be bulkier due to their

larger volume and the greater number of mechanical components. The assembly

process is more complex, leading to higher manufacturing costs.

2. Sensitivity to Contaminants: These fuel

flowmeters are generally sensitive to particulates and contaminants in the fuel.

Installing a filter upstream can increase pressure loss. Additionally,

components such as the rotor and housing require periodic cleaning, which adds

to maintenance efforts.

3. Susceptibility to Flow Rate Variations:

Frequent changes in flow rate can damage the rotating parts. It is crucial to

avoid sudden opening or closing of valves near the diesel flowmeter, as such

actions can lead to instrument damage if not properly managed by the operator.

Despite these limitations, positive displacement flowmeters remain a widely used and reliable fuel flow metering instrument due to their high accuracy and long service life. They are commonly employed in industries such as oil measurement and trading, light manufacturing, food processing, and other sectors.

To conduct a precise error analysis of

mechanical fuel flow meters, one must consider several critical factors.

Assuming the machining precision and assembly standards are upheld, the primary

sources of systematic error include leakage or slippage, which arises due to

the clearance between the measuring element (such as a rotor, scraper, or

piston) and the internal cavity of the housing. Another significant factor is

the change in the volume of the metering chamber, which can occur due to

deformation of the housing caused by fluid pressure, mechanical stress, and

temperature fluctuations.

Leakage is influenced by the gap size,

fluid viscosity, and the pressure differential between the flowmeter's inlet

and outlet (which is related to the movement resistance of the measuring

element, the transmission mechanism, and the fluid's flow resistance within the

housing). While minimizing the gap can reduce leakage, it also increases

manufacturing complexity and risks jamming the moving components, or at the

very least, elevating resistance. Thus, the gap cannot be minimized

indefinitely. The rotor's resistance to rotation, which is overcome by the

pressure differential between the inlet and outlet, coupled with the pressure

loss caused by fluid viscosity within the metering chamber, contributes to the

overall pressure differential that drives fluid leakage through the gap.

Factors such as increasing the gap, decreasing viscosity, increasing pressure

differential, increasing density, and heightened rotational resistance all

exacerbate leakage. For high-precision volumetric flow meters, minimizing leakage

is essential, requiring the rotor to rotate freely with minimal resistance

torque, ensuring a small pressure differential, maintaining an appropriately

small gap, and selecting a fluid with moderate viscosity.

When selecting volumetric flowmeters, particularly for applications like fuel oil product measurement, trade, and

material accounting, careful consideration must be given to ensure optimal

performance and accuracy. The following guidelines should be observed:

When installing and maintaining volumetric

type fuel oil flow meters, particularly for applications involving precise

measurements such as trade or standard delivery, adherence to the following

guidelines is essential to ensure accurate performance and longevity:

1. Install Site Selection: The

installation site should conform to the fuel flow meter's operational

guidelines, ideally being indoors. If outdoor installation is necessary, a

protective enclosure should be used to mitigate the effects of environmental

exposure. For sites with explosion-proof requirements, select a flow meter that

meets the necessary explosion-proof ratings.

2. Installation Precautions: Ensure that

the flow direction indicated on the fuel flow meter aligns with the actual

fluid flow, such as gasoline, diesel. If needed, install a check valve to

prevent reverse flow, except in cases where a bidirectional flow meter is

specifically designed for such purposes. Before installation, the upstream

piping must be thoroughly cleaned, followed by the installation of a filter and

the flow meter. In certain cases, an air eliminator may be required. The valve

used to regulate the diesel flow should be positioned downstream of the flow

meter to maintain a fully filled pipeline during operation. When connecting the

flow meter to the pipeline, avoid applying mechanical stress to the meter's

housing that could cause deformation. The pipeline should be securely supported

to prevent movement, and sufficient clearance should be provided around the flow

meter for maintenance access.

3. Pre-Installation Testing: For fuel flow

meters used in trade or precision measurement applications, metrological

performance should be verified before installation. The diesel flow meter

should only be installed after confirming its accuracy and ensuring operation

within the optimal flow range, as indicated in the calibration certificate.

Fuel Oil Mass Flow Meter2023/03/02A fuel oil mass flow meter is a type of flow meter that is specifically designed to measure the mass flow rate of fuel oil in a pipeline or process system. Coriolis flow meter is a kind of accurate fuel oil mass flow meter.VIEW

Fuel Oil Mass Flow Meter2023/03/02A fuel oil mass flow meter is a type of flow meter that is specifically designed to measure the mass flow rate of fuel oil in a pipeline or process system. Coriolis flow meter is a kind of accurate fuel oil mass flow meter.VIEW Positive displacement flow meter for fuels and oils2021/06/04Why positive displacement flow meters can be used for fuels and oils?Fuels or oils volumetric flow measurement refers to diesel, petroleum based fuels, kerosene, home heating oil, jet fuel, diesel fue...VIEW

Positive displacement flow meter for fuels and oils2021/06/04Why positive displacement flow meters can be used for fuels and oils?Fuels or oils volumetric flow measurement refers to diesel, petroleum based fuels, kerosene, home heating oil, jet fuel, diesel fue...VIEW Low flow fuel flow meter2022/04/18How low flow fuel flow meter work?Fuels, such as gasoline, diesel fuel, bio-diesel, kerosene, and ethanol may run at low flow rate. Such as at ml/min or lph velocity, in that condition, ultra low flow...VIEW

Low flow fuel flow meter2022/04/18How low flow fuel flow meter work?Fuels, such as gasoline, diesel fuel, bio-diesel, kerosene, and ethanol may run at low flow rate. Such as at ml/min or lph velocity, in that condition, ultra low flow...VIEW Positive displacement flow meter2020/05/25Positivedisplacement flow meterA positive displacement flow meter is adevice that helps in measuring the flow rate of various fluids. It measures thevolumetric flow rates of the fluids. These meters a...VIEW

Positive displacement flow meter2020/05/25Positivedisplacement flow meterA positive displacement flow meter is adevice that helps in measuring the flow rate of various fluids. It measures thevolumetric flow rates of the fluids. These meters a...VIEW Mechanical register oval gear flow meter2019/07/09Mechanical counter oval gear flow meter is a kind of in-line positive displacement flow meter where main power is impossible in the field or the field only request basic metering, no output transmissi...VIEW

Mechanical register oval gear flow meter2019/07/09Mechanical counter oval gear flow meter is a kind of in-line positive displacement flow meter where main power is impossible in the field or the field only request basic metering, no output transmissi...VIEW The Complete Manual for Diesel Flow Meters: Coriolis, Oval Gear, and Turbine2018/01/03Diesel fuel powers everything from heavy machinery and transportation to industrial boilers and backup generators, making it a vital component of the global economy. Accurately measuring diesel flow a...VIEW

The Complete Manual for Diesel Flow Meters: Coriolis, Oval Gear, and Turbine2018/01/03Diesel fuel powers everything from heavy machinery and transportation to industrial boilers and backup generators, making it a vital component of the global economy. Accurately measuring diesel flow a...VIEW