In the field of industrial metrology, accurate measurement of fluid flow is the cornerstone of production control, energy management, and trade settlement. Among various flow measurement technologies, PD flow meters are known as the "precision accountants" in fluid measurement due to their direct and reliable measurement principles, especially suitable for applications that require high precision and high-value media.

PD flowmeter, also known as positive displacement flowmeter,is a kind of volumetric flow meter, it is based on a simple and classic idea: continuously dividing the measured fluid (such as fuel, diesel, resin and so on) into known, fixed volume "small units", and calculating the total flow rate by counting the number of these units.

Imagine an ancient process of scooping water: using a standard capacity bucket, repeatedly filling it with water and pouring it out. By counting the number of times the bucket is filled, the total water volume can be accurately determined. The positive displacement flowmeter is the automation and continuous implementation of this process.

Separation: The precise moving parts (such as rotors, pistons, gears) inside the flow sensor measurement chamber form one or more known volume "measuring chambers" with the housing.

Filling and discharging: Fluid flows in, pushing the moving parts to rotate or reciprocate, causing the measuring chamber to periodically fill and discharge fluid.

Counting: Recording the number of cycles (such as revolutions, reciprocating times) of moving parts through mechanical, magnetic, or photoelectric means.

Calculation: Multiply the number of times by the volume of a single measuring chamber to obtain the cumulative flow rate; By counting per unit time, instantaneous flow rate can be obtained.

Due to its direct measurement of fluid volume, its accuracy is almost unaffected by changes in fluid density, viscosity, pressure distribution, and flow velocity. This is the most essential difference between it and speed flow meters such as turbines, vortex flow meter, and electromagnetic meters.

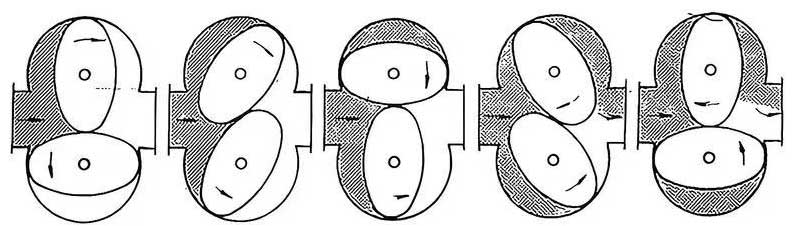

Structure: The shell is equipped with two interlocking elliptical gears that alternately drive rotation under fluid pressure difference.

Work: A crescent shaped measuring chamber is formed between the gear and the housing. Every rotation, discharge the fluid from four measuring chambers.

Features: Classic, durable, high precision, especially suitable for liquids with medium to high viscosity, such as oil products and chemical raw materials. There are certain requirements for fluid cleanliness.

Structure: A pair of "8" - shaped waist wheel rotors with no teeth on the surface, maintained by synchronous gears for non-contact and constant speed rotation.

Working principle: Similar to elliptical gears, but the waist wheel does not directly contact, resulting in less wear and can withstand higher pressure differentials.

Features: The measuring chamber has a larger volume and is suitable for high flow measurement of low viscosity liquids (such as diesel and solvents) and gases.

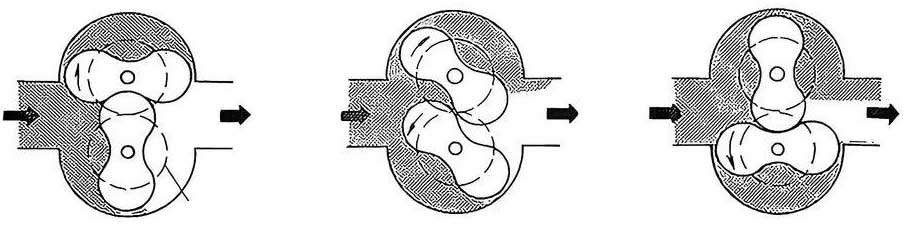

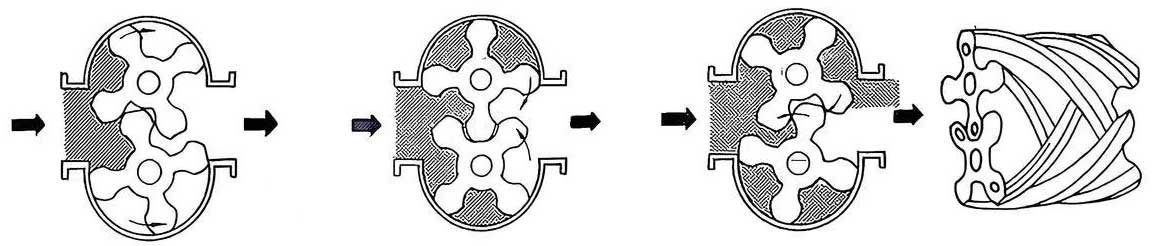

Structure: Unique design with two spiral or involutes rotors.

Work: The rotor maintains continuous contact during rotation, forming a smooth and pulsation free propulsion motion, similar to the reverse process of a screw pump.

Features: Extremely smooth operation, low noise, small pulsation, wide range ratio comparing with oval gear flow meter, and no requirements for upstream and downstream straight pipe sections, making it an ideal choice for high-performance and high reliability applications.Structure: A sliding scraper is installed in the radial groove of the rotor. Under the action of centrifugal force and fluid pressure, the scraper extends and slides tightly against the inner wall of the measuring chamber.

Job: The scraper separates the fluid into multiple independent chambers and pushes it forward.

Features: High precision, low vibration, strong adaptability, able to handle a certain range of viscosity and cleanliness, commonly used in key measurements such as aviation fuel and finished oil.Structure: Fluid is measured by the reciprocating motion of the piston within the cylinder.

Work: The fluid drives the piston to move and the flow path switching is controlled by the crank connecting rod or valve group mechanism to achieve continuous suction and discharge.

Characteristics: It can maintain extremely high accuracy even at low flow rates and is a standard instrument for fuel dispensers, laboratories, and small flow measurement, but its structure is relatively complex.

Structure: A slotted rotating piston rotates eccentrically in a specially shaped measuring chamber.

Job: The swinging and rotating of the piston separates and discharges the fluid.

Features: Compact structure, low cost, widely used in household water meters, small industrial occasions for water and low viscosity liquid metering.

Extremely high measurement accuracy: It is one of the most accurate types of flow meters currently available and is often used as a benchmark instrument for trade settlement and standard transmission. The highest accuracy can reach ± 0.2% or even higher.

Measurement is independent of fluid characteristics: insensitive to viscosity changes, the same meter can adapt to fluids with a wide viscosity range (especially suitable for oil products or high viscosity fluids like honey, crude oil and bitumen).

No need for front and rear straight pipe sections: Its measurement principle does not rely on fully developed flow velocity distribution, and requires low installation space, especially suitable for situations with limited space.

Wide range: The typical range ratio can reach 10:1, and high-performance models are even wider, such as 20:1, capable of accurately measuring both small and large flow rates.

Direct measurement of volume: Accurate total volume can be obtained without the need for additional pressure or temperature sensors for density compensation, and the system composition is simple.

PD flow meter is sensitive to the cleanliness of the medium: Solid particles and impurities can get stuck or wear down precision moving parts, causing malfunctions or decreased accuracy. So keep in mind, always measure clean and pure liquid, It is usually necessary to install a filter in front of the PD flow instrument, or you can choose Coriolis flow meter if the particles are inevitable.

Significant pressure loss: Due to the fluid's need to overcome the resistance of moving parts, permanent pressure loss occurs, which increases with viscosity.

Flow sensor is with moving parts: The mechanical structure is complex, there are moving parts inside, and there is mechanical wear that requires regular maintenance, calibration, and lubrication (self-lubricating or external lubrication).

Not suitable for large diameters: The structure and pressure loss limit its application on large diameter pipelines (usually larger than DN300, 12 inches).

Possible vibration and noise: especially when gears or rotors mesh, pulsation and noise may occur in the system.

Trade handover: Accurate buying and selling settlement of high priced media such as crude oil, refined oil (gasoline, diesel), and liquefied petroleum gas (LPG), etc., commonly using oval gear flow meter, bi rotor, and scraper flow meters.

Process control: batching and loading/shipping of high viscosity products such as lubricating oil, mold oil, grease, fuel oil, asphalt, etc.

High viscosity medium: batch metering and filling of resin, polymer, coating, xylem, solvent, essence, syrup, etc.

High purity/corrosive media: Flow meters made of special materials such as stainless steel are used to measure chemical raw materials.

Sanitary measurement: quantitative filling and production ingredients for foods such as chocolate, jam, edible oil, dairy products, beer, beverages, etc. R

Aerospace: Precise refueling and testing of aircraft fuel.

Ship: Management of refueling and consumption of marine fuel.Laboratory: used as a standard table or for small flow, high-precision scientific research experiments.

The price of PD flow meters is influenced by various factors, including material (such as cast iron, aluminum, cast steel, or stainless steel), pipe diameter size ( 1 inch and 8 inch PD flow meter has total different price) , and pressure rating ( standard 16 bar pressure, if you need 580 psi higher pressure , it will cost more). The price difference is significant under different configurations and operating conditions. Silverinstruments.com, known for its high-quality flow meter, offers cost-effective options for customers with limited budgets but clear needs by offering some models of volumetric flow meters that can be priced below $1,000 while ensuring reliable performance.

As a mature and classic measurement technology, volumetric flowmeter still holds a stable position in the field of flow measurement that pursues high precision and reliability. Despite its limitations such as high requirements for medium cleanliness and the presence of moving parts, it remains an irreplaceable preferred solution in specific scenarios such as handling high viscosity liquids, conducting trade settlements, and limited installation space. With the advancement of materials science and electronic technology, modern volumetric flow meters continue to improve in terms of wear resistance, self diagnosis, digitization, and communication capabilities, ensuring that this "fluid precision accountant" continues to play its irreplaceable core value in the future industrial intelligence process.

Ultra Low flow to 0.5 ml/minHigh accuracy 0.5% reliable volumeCompact size,high pressure readywork with thin or thick liquids

Positive displacement sensor (4-20mA).High accuracy for various fluids.Compact and durable design.Easy integration with systems.

NPN or PNP pulse outputHigh accuracy 0.2-0.5% totalHandles diesel fuel and lubePulse output for PLC and DCS

RS485 MODBUS RTU FlowmeterDigital display show total and instant flowExd housing design for safetyHigh accuracy PD flow meter

4-20mA analog outputWide viscosity rangeHigh accuracy from ±0.2%Easy field installation

NPN or PNP pulse outputExplosion Proof pulseHigh accuracy ±0.5% or betterViscous liquid ready

High accuracy: ±0.2% readingFlow Unit: Liter/US Gallon/IMP Gallon1.5" to 6 inches sizeLow maintenance

Positive displacement flow meterMechanical/analog flow meterReturn-to-zero optionFor fuel, diesel, oil measurement