We have received many gas flow measurement application inquiries from industries worldwide. Since gas flow measurement involves multiple dynamic variables such as temperature, pressure, and moisture content in the gas stream, selecting a suitable gas flow meter is considered to be more challenging than choosing a liquid flow meter. At Silver Automation Instruments, before our engineers can suggest the proper size gas meter for your needs, they need to know the type of gas being measured, the operating temperature, and the operating pressure.

Some clients are confused about the different units of gas flow rate that are often seen in specifications and datasheets, such as:

The prefixes have specific meanings:

But what exactly are these differences, and why do they matter?

This confusion arises because gases are compressible,which means that their volume changes a lot with temperature and pressure. Depending on how you measure it,The same amount of gas could take up vastly different amounts of space. The gas industry use three flow measurement systems (Actual, Standard, and Normal) to deal with this problem. You need to know these to select proper equipment and measure accurately.

- Standard Flow Rate

Standard flow rate (like Sm3/h, SCFM) adjusts your actual flow reading to a common reference point, like converting currency. his enables you compare measurements from diverse situations on an equal basis. The adjustment uses the ideal gas law (PV = nRT), which relates pressure, volume, and temperature..

Most common standard conditions:

Keep in mind: Different regions and industries have somewhat varying standard conditions, so always double-check which standard applies to your application.

- Normal Flow Rate

Thermal mass flow meter with normal flow rates

Normal flow rate (like Nm3/h) works the same way as standard flow,except it uses a different reference temperature:

Normal conditions:

You'll see this used more often in European standards and in chemical or petrochemical industries.

- Actual Flow Rate

Actual flow rate display by flow meter

Actual flow rate is what's really happening in your pipe right now: the real-time volume of gas flowing through at your current operating temperature and pressure. No adjustments, no corrections.

Here's what affects it: when temperature goes up, gas expands and actual flow increases; when pressure goes up, gas compresses and actual volume decreases.

Silver Automation Instruments offers several solutions:

Measure mass flow directly with automatic temperature and pressure compensation built in

Great for steam and gas applications, includes temperature compensation

High accuracy gas measurement perfect for pipes less than 16 inches

Quick Reference Comparison Table

|

Flow Type |

Reference Pressure |

Reference Temperature |

Typical Use |

Common Units |

|

Standard |

101.325 kPa (14.696 psia) |

15°C (59°F) or 60°F |

US markets, billing |

SCFM, Sm³/h |

|

Normal |

101.325 kPa (14.696 psia) |

0°C (32°F) |

EU markets, chemical industry |

Nm³/h, NLPM |

|

Actual |

Process pressure |

Process temperature |

Equipment sizing, control |

ACFM, Am³/h |

Understanding these flow rate types directly impacts your operations and costs:

Practical Example:

Consider a gas flowing at:

When corrected to standard conditions (101.325 kPa and 15°C):

The standard flow rate might be approximately 450 Sm³/h

This demonstrates why the distinction matters—the same gas flow has dramatically different values depending on which reference conditions are used.

Conversion Between Flow Types:

To convert between actual, standard, and normal flows, you'll need to apply gas law corrections:

Basic conversion formula:

Q₁/Q₂ = (P₁/P₂) × (T₂/T₁) × (Z₂/Z₁)

Where:

Step-by-Step Conversion Example:

Converting 100 Am³/h at 5 bar and 50°C to Standard conditions (1.01325 bar, 15°C):

1.Convert temperatures to Kelvin:

2.Use pressures in absolute values:

3.Apply formula (assuming Z₁ ≈ Z₂ ≈ 1 for ideal gas):

Avoiding these common errors can save you time, money, and help you get accurate measurements and can make correct decisions.

What happens: You order a flow meter sized for 100 Sm³/h, but your system is actually running at 100 Am³/h at elevated pressure.

Result: The gas flow meter may be undersized,it may cause excessive pressure drop, unstable readings, or even damage if gas flow is over the gas flow sensor can detect.

Solution: Always clarify to silverinstruments.com whether the required gas flow rate is actual, standard, or normal (or we say operation), and provide full operating conditions to sales engineering of silverinstruments.com.

What happens: You apply the simple ideal gas law to measure high-pressure natural gas without considering how real gases actually behave.

Result: Measurement errors can easily reach 5–15% or even higher once pressure goes above 50 bar, and also at such high pressure rating , the gas flow sensor can break.

Solution: Always include Z-factor corrections in high-pressure applications or whenever the gas doesn’t behave ideally.

What happens: Measuring wet gas as if it were completely dry gas , ignoring the water vapor content..

Result: Overstated gas volume, incorrect material balance, poor measurement accuracy or billing issues.

Solution: Specify whether gas is wet or dry when inquiry gas flow meter from silverinstruments.com, actually most gas flow meter technologies have poor performance on wet gas measurement. Use moisture separators or meters specifically designed for wet gas when needed.

What happens: Installing temperature sensors in locations with poor thermal contact or trapped air.

Result: Inaccurate temperature readings cause compensation errors.

Solution: Follow manufacturer installation practices and use properly sized thermowells with adequate immersion and thermal compound.

What happens: comparing quotes where one vendor uses Sm³/h (at 15°C) and another uses Nm³/h (at 0°C), without converting between them.

Result: You're seeing different prices because you're comparing the wrong things. This leads to wrong equipment choices.

Solution: Always convert all specifications to the same reference conditions before comparison.

Different industries have specific needs when it comes to flow measurement. Here’s how different applications tackle their unique challenges:

Natural gas flow measurement

Requirement: Standard flow measurement (typically 15°C, 101.325 kPa) for billing

Key Challenges:

Solution: Turbine with automatic pressure sensor and temperature sensor compensation. Or you can use Coriolis flow meters which can directly measure natural gas (NG) mass flow .

Compressed air flow measurement

Requirement: Actual compressed air flow measurement for leak detection and efficiency monitoring

Key Challenges:

Solution: Thermal mass flow meter or vortex flow meter (good price/performance)

Benefits: Can cut energy waste by 20-30% by catching leaks early

Requirement: Normal flow measurement (0°C, 101.325 kPa) commonly used in many facilities for stoichiometric calculations

Key Challenges:

Solution: Coriolis meters for mass, or thermal mass flow meter; backup meters for critical processes

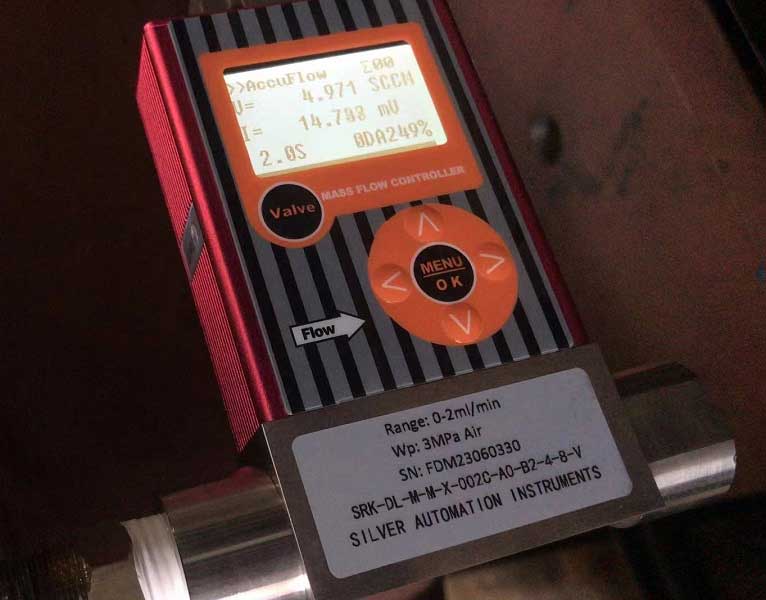

Thermal mass flow controllers (MFC)

Requirement: Ultra-precise mass flow control measured in SCCM (Standard Cubic Centimeters per Minute)

Key Challenges:

Solution: Thermal mass flow controllers (MFC) with ±1.0% of reading accuracy and ±0.2% repeatability

Primary Requirement: Standard volumetric flow for regulatory compliance reporting

Key Challenges:

Solution: Ultrasonic (non-intrusive), DP flow meter or thermal mass meters; sampling systems to check gas composition

This is usually because our meter is probably showing actual flow (Am³/h), but your supplier bills based on standard flow (Sm³/h or Nm³/h).

The difference can be significant at 5 bar pressure where 100 Am³/h ≈ 500 Sm³/h. Make sure your flow totalizer or computer applies the correct pressure and temperature compensation to match the billing.

We recommend mass flow meters when:

If your gas composition is stable and conditions are moderate, volumetric meters with pressure/temperature compensation are usually more affordable and work just fine.

It depends on what type of meter you have:

Our advice: Do check with your supplier before switching gases. We've seen accuracy drop a lot when users change gases without properly reconfiguring.

This is critical for getting your flow calculations right:

The formula you need: P_absolute = P_gauge + P_atmospheric (approximately)

Example error: If you use 5 barg instead of 6.01325 bara in compensation calculations, your standard flow will be reduced by almost 17%.

We recommend different schedules depending on how you use the meter:

The good news: Many modern meters have built-in diagnostics that will inform you when performance begins to degrade, eliminating the need to guess.

We hope this guide has helped you understand the critical differences between actual, standard, and normal gas flows, so you can:

✓ Specify gas flow requirements correctlyWe should understand these fundamentals well if we want our gas flow measurement projects to succeed. Whether you're designing a new system, troubleshooting issues, or optimizing performance, the difference between actual, standard, and normal flows affects every part of your measurement system.

Need Help With Your Specific Application?

Our experienced engineers at Silver Automation Instruments are here to help you select the right solution for your gas flow measurement needs.

Email us: sales@silverinstruments.com

Whatsapp: +86 18936759191