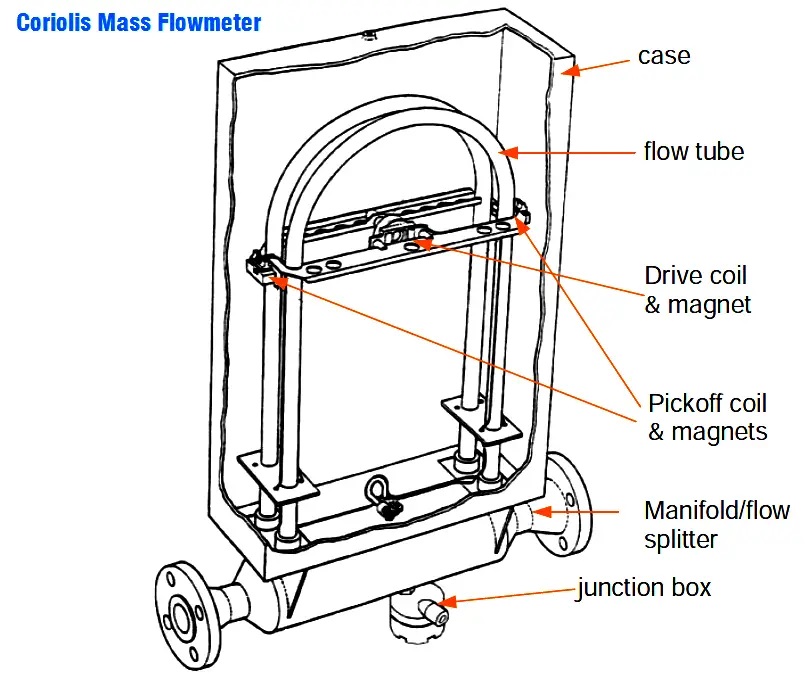

This demonstration represents approximately 21% of all the flowmeters sold. Acoreolis flowmeterworks with vibration. The swinging of the tubes is generated by vibration. Flow Sensor are used with the Coriolis mass flowmeter in order to generate an accurate linear flow signal. These are two very important components for finding the linear flow signal.

SH-CMF series Coriolis mass flow meters are low price and rugged replacement for below top brands Flow meters,

The technology of the coriolismass flow measurementhas very high reliability and accuracy rates. The Coriolis mass flowmeters can handle sanitary applications. The Coriolis mass flowmeter is also low maintenance which is a benefit. Mass flow is significantly more important compared to volume of of fluid when used for producing energy. Some examples of this are petroleum liquids and natural gasses. Natural gasses that are compressed and liquified apply to this, it can be used as CNG flow meter . The cost is relatively high. The cost can be especially high for mass flowmeters that are above four inches. Pressure drop can also be considered for tubes that are "U" shaped as well as fluids with high viscosity.

Coriolis mass flowmeters are primarily used for measuring liquids such as acids, chemicals, vapors and more. The intent of the mass flow meter is to accurately measure these above substances. Measurement is not affected by changes in fluid density. It is important to exercise caution when using mass flowmeters with gases as they tend to produce low flow ranges and can cause degraded accuracy. It is also important to note that vapor and gas applications can cause piping and pressure drops.

There are a few main purposes for flow

meter coriolis type such as sanitary, relatively clean, cryogenic, corrosive

liquids and vapors. Pipes smaller than 12 inches can accommodate these. Some of

the most common general applications include wastewater, mineral processing, pulp,

paper, power as well as petrochemical industries. Chemical feed systems use

Coriolis mass flowmeters as well. The applications for this meter are used in

industries that produce corrosive fluids that would present issue with

measuring otherwise. This is very important to note as it ensures that the

right tool is used for the purpose of accurately measuring. For viscous liquid

, they have obvious advantages , such as asphalt, curde oil, honey,grease.,etc,

it is a kind of high viscosity flow meter.

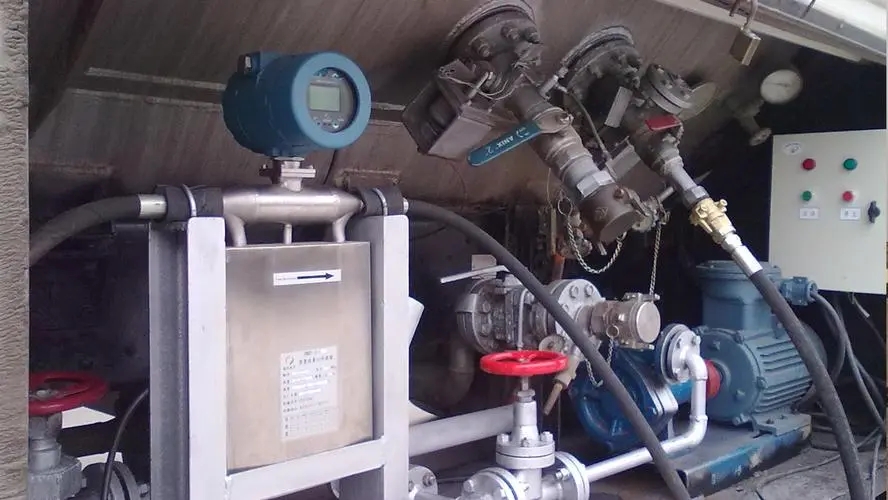

The industries that utilize the Coriolis mass flowmeter are oil, gas, food, beverage, paper, pulp. pharmaceutical, mining, metals and wastewater. In addition to these main industries, there are also other ones that utilize the flowmeter to a lesser degree as well.

Smaller installation size.

Max sensor size 10 inches.

Profibus PA/HART/MODBUS.

Better for high viscosity or slurry liquid.

Direct mass flow measurement.

High accuracy: 0.1 %~0.2%.

Also measure density, temperature, pressure.

For all fluids measurement.

All kinds liquid measurement

Density measurement as well

Fuel, syrup, polymer, molasses

Also, can measure corrosive liquid

Large size : 4",5",6",8" 10",12 inch.

Max flow range: 1000 ton/hour.

Option with high pressure design.

Direct mass flow crude oil, fuel and so on.

Good for high pressure or high density gas.

Direct mass flow measurement.

No straight pipeline needed for install.

For LPG, natural gas, H2,O2,Ar,Cl₂ ....

Max temperature upto 350 °C( 662℉).

Mass flow meter for all kinds fluids.

Option with heating jacket

For bitumen, liquid metal, hydrocarbon oil……

Tri-clamp or DIN 11851 end fitting

316L SS wet parts material

For wine, molasses, honey, milk, yogurt, chocolate……

for food, dairy, bio-technology, pharmaceutical industry

Max work on 700 bar high pressure.

The high pressure type flow sensor is needed in such as chemical injection or hydrogen fueling station.