Related Products

Ultrasonic Open Channel Flow Meter

4-20mA & MODBUS-RTU standard

For Weir and flume flow measurement.

Introduction to Bidirectional Magnetic Flow MetersBidirectional magnetic flow meters are marvels of modern engineering, offering a highly efficient and accurate solution for measuring fluid flow. Thes...

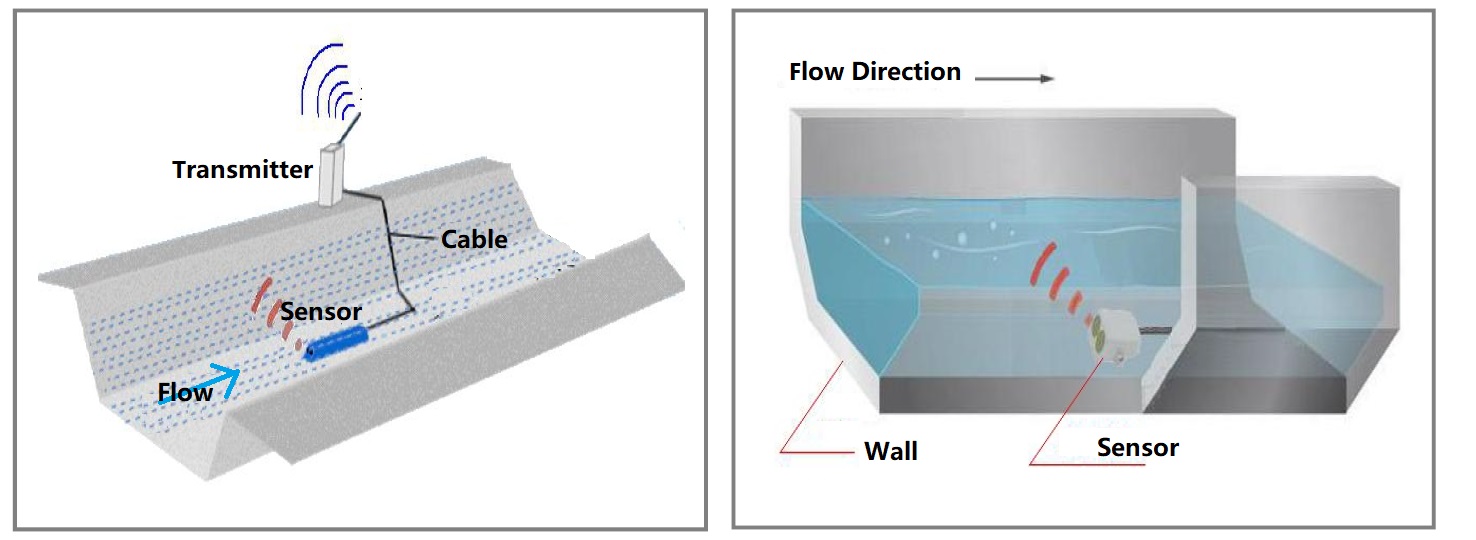

The Doppler ultrasonic open channel flow

meter is a device used to measure the flow rate of partially filled pipes or

channels.

Principle of SLH-OP Series Partially Filled Pipe Ultrasonic Flow meter

Measuring the Doppler shift resulting from the reflection of an ultrasonic beam off reflective materials, such as solid particles or entrained air bubbles in a flowing fluid, or the turbulence of the fluid itself, allows for the calculation of flow velocity. By utilizing the speed of sound through air, the distance from the sensor to the liquid level can be determined. Flow through the channel can then be calculated based on the level measurement; with the user inputting properties of the channel. It calculates the flow rate based on the average flow velocity, water depth, and water temperature. The device can also display the cross-sectional flow rate.

The water temperature is measured using a temperature probe, which is placed on the top of the instrument and needs to be submerged in water for a certain amount of time to reflect the actual water temperature. This is done to calibrate the speed of the ultrasonic waves in water and correct the water level values measured by the pressure sensor. The water depth is measured using a high-precision pressure sensor placed at the bottom of the instrument, with the sensing part in direct contact with the water.

Advantages of SLH-OP Series Partially Filled Pipe Ultrasonic Flow meter

Technical Specification

|

Velocity |

Range |

21 mm/s~5000 mm/s |

|

Accuracy |

± 1% of measured velocity |

|

|

Resolution Ratio |

1 mm/s |

|

|

Temperature |

Operation Temperature |

0 °C~ 60°C |

|

Resolution |

0.2 °C |

|

|

Level |

Range |

0~10m |

|

Resolution |

1 mm |

|

|

Accuracy |

± 0.5 % of measured level |

|

|

Flow Rate |

Accuracy |

± 2 % of measured flow |

|

Power supply |

12V DC or 220V AC |

|

|

Communication |

RS 232,RS485 ,4-20mA |

|

|

Protocol |

MODBUS |

|

|

Data Storage |

Data is collected every 10 minutes and can store data for over 6 months. Even in the event of a power outage, this data will not be lost for a long time. |

|

|

Operation Temperature |

0 °C~ 60°C |

|

|

Housing Material |

PC or PVC plastic |

|

|

Protection Level |

IP68 |

|

|

Reliable |

MTBF≥25000h |

|

|

Size |

230×90×37 mm (probe) and 257×179×70 mm (terminal). Standard communication cable length is 10m, extendable up to 1000m. |

|

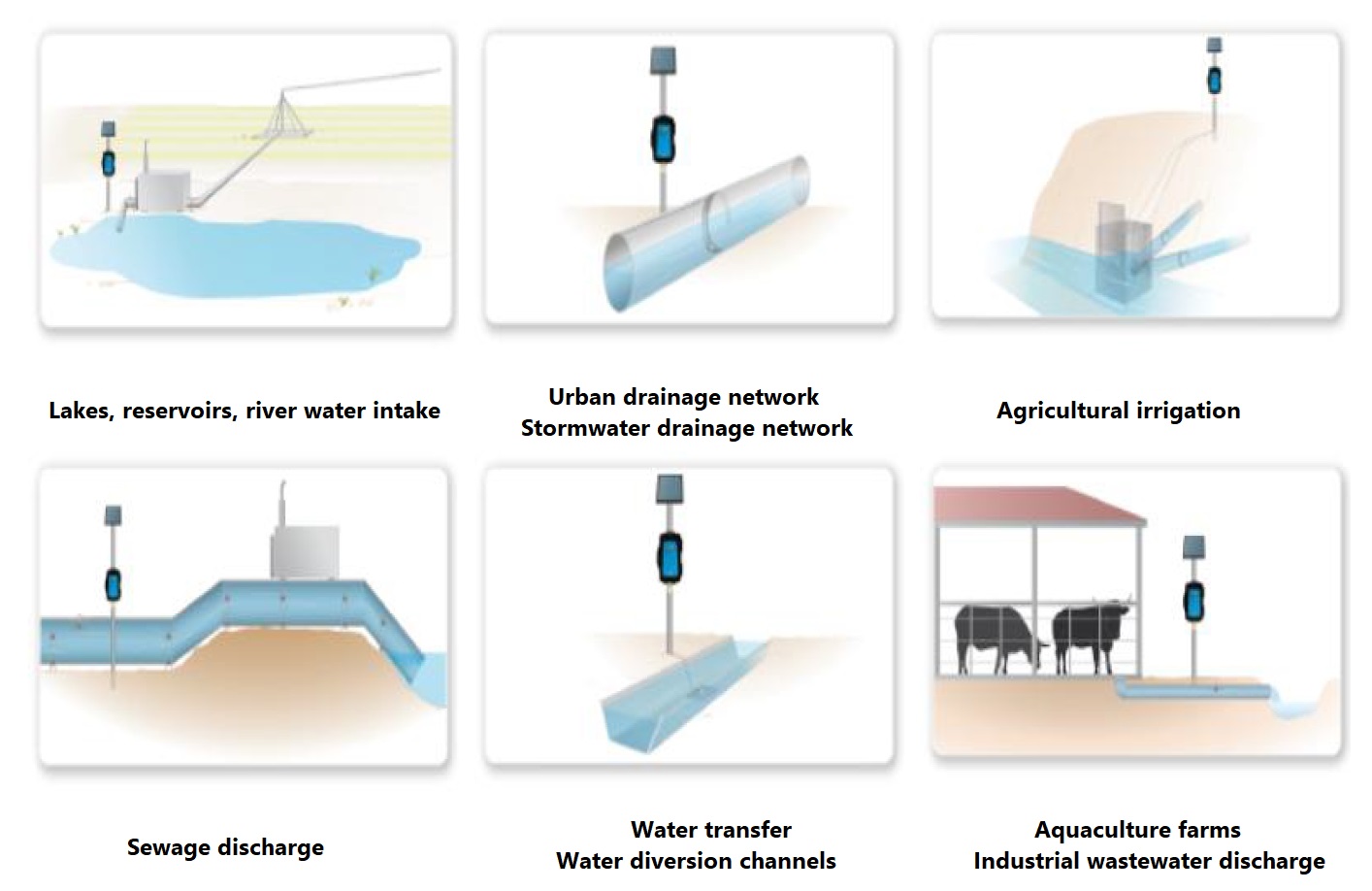

Applications

Site Pictures

we will contact you within 24 hours.