Inhibitors and Biocides: Importance of Accurate Level Measurement

Inhibitors are widely used in many fields such as antibacterial, mildew proof, and disinfection and other ideal antibacterial agents. Biocides control or kill microorganisms, bacteria, fungi and algae in water systems. The main fields are agricultural fungicides and industrial fungicides.

Inhibitors and Biocides are corrosive liquid, and it is important to take level measurement of inhibitors and biocides.

Non-Contact Liquid Level Measurement for Various Industries

Liquid level measurement has been widely used in petroleum, chemical, meteorological and other industries. The realization of

non-contact level measurement and intelligent measurement is the current development direction of liquid level meters. With the research and development of high and new technologies such as computers, microelectronics, and sensors, the development of ultrasonic liquid level instruments has made great progress in recent years, and has been rapidly updated to meet higher and higher application requirements; it is a perfect solution for Inhibitors and Biocides Level measurement.

How Ultrasonic Level Sensors Work

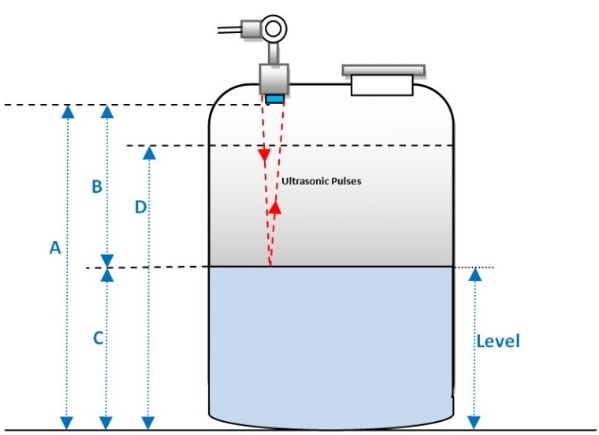

Ultrasonic level sensor is the fastest growing instrument in non-contact level measurement. Ultrasonic level transducer works based on the principle that ultrasonic waves are reflected on the surface of the object to be measured, and the principle that the measured distance is a function of time. Ultrasonic level probe has the advantages of wide measurement range; measurement is not affected by medium density and dielectric constant. Ultrasonic level detector is suitable for a variety of measurement media such as liquid or solids ,powder , so it has a very wide range of applications, including water channels, oil tanks, gas tanks and other occasions, and can also be used in viscous, corrosive and toxic liquids. Such as corrosion inhibitors and biocides level measurement.

Applications of Ultrasonic Level Transmitters

Ultrasonic

liquid level transmitters are used in the water level measurement of rivers, lakes, water, canals and other water bodies, as well as in the liquid level measurement of oil, slurry and other liquids. Ultrasonic liquid level measurement technology plays an important role in more and more fields. Ultrasonic level transmitter for inhibitors and biocides has the characteristics of advanced technology, high measurement accuracy, wide measurement range and good long-term operation stability, and is favored by many customers. The maximum range of SILVER HL series ultrasonic level sensor is 40m, and its accuracy is as high as 0.2% of the range, which is very high precision ultrasonic level sensor. At the same time, Ultrasonic level sensor and transmitter supports 4~20mA two-wire or four-wire power supply.

Feature of Inhibitors and Biocides Level Sensors ultrasonic type

Ultrasonic level sensors has may level ranges, such as 0-4 mts, 0-6 meters, 0-8m,0-12 meters,0-65ft, 0-30m,max 130 ft.

Digital ultrasonic level sensor 4-20mA, MODBUS, HART,

PROFIBUS-DP protocol ultrasonic level transmitter options;

Ultrasonic level sensor with remote display or option with integral displays

Communication Protocols and System Integration for ultrasonic level transmitter

Many Inhibitors and Biocide ultrasonic level sensors use digital interfaces to easily provide the signals required for telemetry and remote control, especially with various fieldbus interfaces, which can be easily connected to the entire automation management system. Such as HART communication protocol, MODBUS RS485, PROFIBUS DP communication protocol, so that users can obtain ultrasonic liquid level measurement information from many places, obtain timing Inhibitors and Biocides level and volume information, and achieve ideal online control. This is an intelligent integrated non-contact continuous level measuring instrument suitable for various process control systems, which represents the development direction of liquid level measuring instruments.

Ultrasonic level sensor Material Options and Compatibility for Corrosive Liquids

HL series ultrasonic liquid level measuring instrument has a variety of wetted material options, such as ABS or PTFE material, which can measure corrosive liquids, such as pesticides, inhibitors and Biocides.

Ultrasonic transmitter Advanced Signal Processing for Accurate Measurements

The intelligent ultrasonic level meter can accurately process and analyze the received signal: non contact ultrasonic level sensor can filter out various interference signals from Inhibitors and Biocides tanks, identify multiple echoes, and analyze the signal strength and ambient temperature and other related information. This enables accurate measurements even in the presence of external disturbances.

With the patented technology of ultrasonic intelligent signal processing and extremely high signal-to-noise ratio indicators, non contact ultrasonic level sensor has the automatic false echo suppression function to eliminate the interference of fixed obstacles, which effectively avoids the influence of fixed obstacles on the measurement.

Robust Design for Harsh Environments

Due to the diversification of the measurement objects of the ultrasonic level sensor, such as industrial wastewater, bleaching liquid, resin and various solutions, and the harsh environment (high temperature, noise, moisture, etc.), high-quality ultrasonic level sensors with robust construction to meet the demand.

Temperature Compensation for Enhanced Accuracy of level measurement

The ultrasonic level transmitter is equipped with an integrated temperature sensor, which can perform temperature compensation for the indicated value to make Inhibitors and Biocides more accurate. The level sensors can perform linear correction, and has the functions of secondary echo detection, automatic suppression of interference echoes, and parameter locking.

Reliable and Scalable Ultrasonic Level Measurement Solutions

The system has high measurement accuracy, stable and reliable long-term operation, strong adaptability to the working environment, strong lightning protection capability for on-site instruments, flexible communication protocols, and good system scalability for Inhibitors and Biocides.

HL Series ultrasonic level sensors from

China ultrasonic level sensor and transmitter manufacturer, which has low price cost and reliable performance, can replace rosemount, endress+hauser