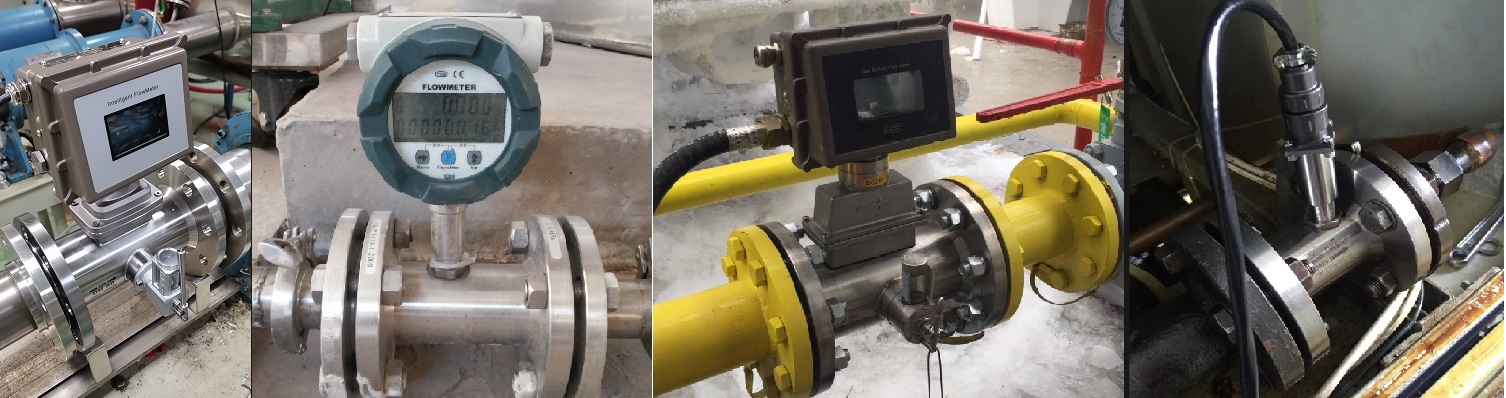

Turbine flow meters are one of the most widely used and reliable instruments for volumetric flow measurement. With their simple design, high accuracy, and affordable price, turbine flow meters have become essential in industries such as oil and gas, water and wastewater, chemical, food and beverage, and power generation. Depending on the medium, turbine meters are divided into gas turbine flow meters and liquid turbine flow meters, both available in a wide range of sizes, connections, and digital output options. For a more detailed introduction, visit What is Turbine Flow Meter?

An electronic turbine flow meter for gas (also known as TUF or gas turbine meter) is engineered for precision gas metering. These rugged instruments comply with international standards and are tested before shipment to ensure top performance.

Accuracy:1.0–1.5% of reading,Discover how to achieve even better accuracy here

Pressure ratings:Standard PN16, optional 300 PSI, 300LB, or 600LB high-pressure designs

Power supply:Battery-powered or 24 VDC loop power

Outputs:4–20mA, pulse, RS485 MODBUS RTU , or HART communication

Display:LCD showing instant gas flow rate and totalized volume

Optional EVC (Electronic Volume Correction)integrates temperature (RTD) and pressure sensors for compensated, corrected gas measurement.

Gas turbine meters are suitable for:

Natural gas, biogas, methane, compressed natural gas (CNG),LPG gas

Industrial gases: Air, nitrogen (N₂), oxygen (O₂), helium (He), carbon dioxide (CO₂), ethylene (C₂H₄)

Hydrocarbon gases: propane, butane

Compressed air and process gases

1” gas flow transmitter: 42–420 LPM

3” (DN80): 5.5–111 L/s

4” (DN100): 20–400 m³/h

6” (DN150): 50–1000 m³/h

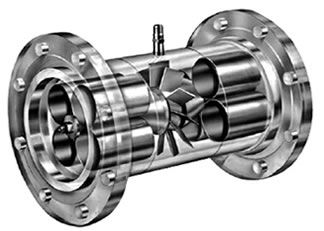

A liquid turbine flow meteruses the kinetic energy of the fluid to rotate a rotor inside the meter body. The rotor speed is directly proportional to the flow velocity, allowing for accurate volumetric flow measurement.

Accuracy:0.5–1.0%

Flow sensor Temperature limit:Up to 150 °C high temperature

Flow sensor materials:Stainless steel 304 or 316

Connections:Thread (NPT/BSP), wafer, flange (ANSI, JIS, DIN), or tri-clamp sanitary type turbine flow sensor

Power supply:3.6V lithium battery, 24 VDC, or 220V AC

Turbine flow transmitter outputs:Pulse (PNP/NPN), frequency, 4–20mA, HART, MODBUS RTU

Liquid turbine meters are widely used in clean, non-corrosive liquids such as:

Water:Tap water, RO water, soft water, distilled water, demineralized water, condensate

Fuels and oils:Diesel, biodiesel, fuel oil, petrol, kerosene, jet fuel, vegetable oil, palm olein, edible oils, coconut oil

Chemicals:Acetic acid, ethyl alcohol, acetone, toluene, xylene, butyl acetate

Food & beverage:Milk, alcohol, edible oils,wort, vegetable oil Flow meter

From micro turbine flow meters(1/8”, 1/4”, 3/8”, 1/2”) for low flow measurement, to industrial sizes (3/4”, 1”, DN50, DN80, DN100, DN150, DN200, DN300).

For more common questions and detailed technical answers about liquid turbine flow meters, please check our FAQ for SLW Series Liquid Turbine Flow Meter.

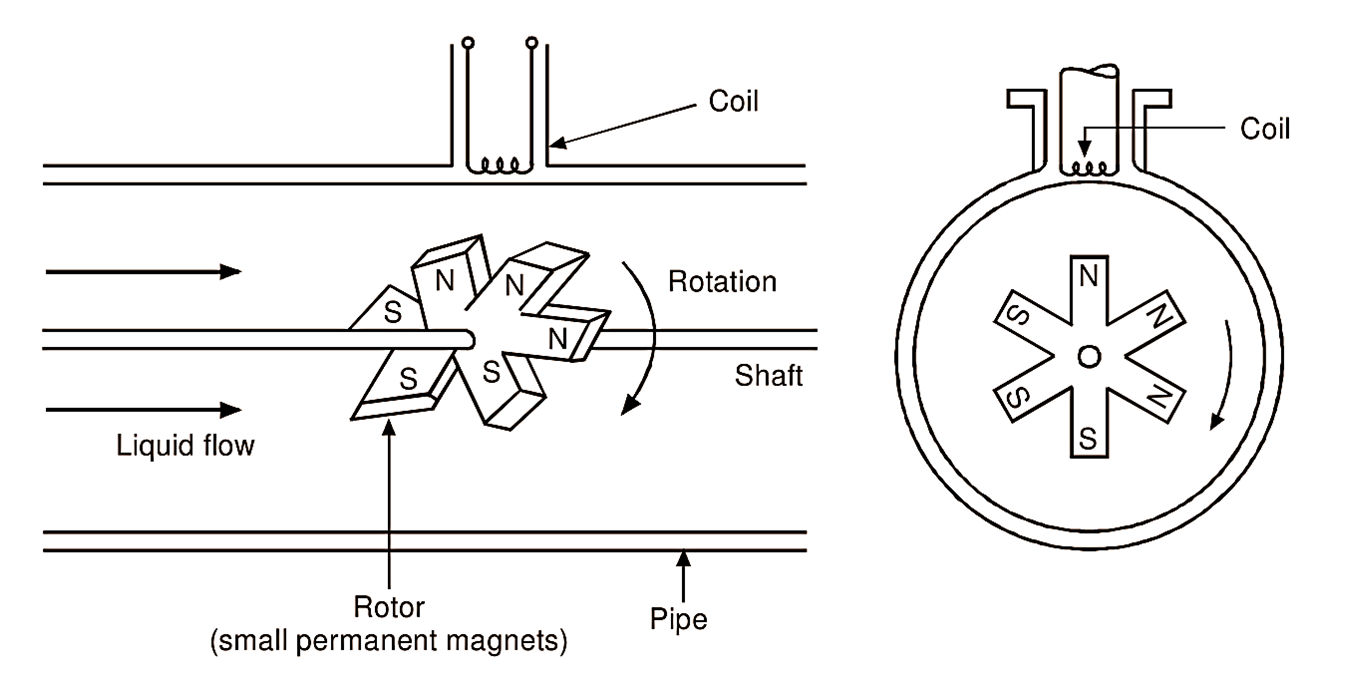

The working principle of a turbine flow meter is simple yet effective:

The medium enters the flow body and drives therotor blades.

The rotation speed is proportional to the fluid velocity and volumetric flow rate.

As each blade passes through the magnetic pickup, it generates a voltage pulse.

The electronic transmitter converts these pulses into flow rate and total volume.

To ensure smooth operation,low-pressure-drop designs and precision bearings are used. Proper installation avoids turbulence and ensures long service life.

✔ High accuracy (0.5–1.5%)

✔ Cost-effective compared to other flow technologies

✔ Compact and rugged design

✔ Fast response time

✔ Wide range of output options (frequency, analog, digital, MODBUS, HART)

✔ Suitable for both conductive and non-conductive liquids

✔ Available in sanitary, threaded, flanged, and wafer connections

For more details on their benefits and proper usage, see our Advantages and Usage of Turbine Flow Meter

Accuracy decreases at very low flow rates .Silver Automation Instruments delivers tailored solutions for micro and low flow applications — see details here: Low Flow Flow Meter.

Bearing wear over time, especially with non-lubricating fluids. If you are looking for a no moving parts flow meter, please contact us

and we will help you choose the right solution.

Not suitable for dirty or slurry-type fluids,but we offer dedicated slurry flow solutions: Slurry Flow Meter.

Cannot handle two-phase flow (gas-liquid mixture)

Limited temperature ranges compared to advanced technologies.but for high-temperature applications we offer solutions: High Temperature Flow Meter

Oil & Gas:Custody transfer of natural gas, petroleum, fuels, diesel, jet fuel

Water & Wastewater:Monitoring clean water, RO water, demineralized water

Chemical:Measuring solvents, alcohols, acids, and process fluids

Food & Beverage:Milk, edible oils, alcohol, palm oil, fish oil, and sanitary liquids

Power Generation & Aerospace:Cooling water,chilled water, fuel supply, test benches

The cost of a turbine flow meter depends on:

Medium type:Gas turbine vs. liquid turbine meter

Size:From micro flow sensors to DN300 industrial meters

Electronics:Local display, digital output, MODBUS/HART options

Pressure & temperature rating:Standard vs. high pressure/high temperature versions

Material:SS304, SS316, or special alloys

Silver Automation Instrumentsprovides affordable alternatives to premium brands (e.g., Cameron Nuflo, Blancett, Daniel, Omega, Badger, Emerson, K24) while maintaining reliable performance.

For a deeper look at the key factors that affect turbine flow meter pricing, visit our detailed guide.

Proper installation is critical to ensuring the accuracy and longevity of turbine flow meters. For liquid applications, meters should be installed in a straight pipe section with minimal flow disturbance, avoiding pumps, valves, or elbows too close to the meter. For gas turbine flow meters, careful attention should be given to pressure, temperature, and cleanliness of the pipeline to prevent measurement errors and premature wear. Following best practices helps maximize performance and reduce maintenance needs. Learn more in our Liquid Turbine Flow Meter Installation Guide and Gas Turbine Flow Meter Installation Tips.

The turbine flow meter remains one of the most practical and cost-effective solutions for gas and liquid flow measurement. With its high accuracy, fast response, and versatility, it continues to be a preferred choice inoil & gas, chemical, water, and food industries worldwide.

When selecting a turbine flow meter, always specify thefluid type, flow range, operating pressure, and temperatureto ensure the best performance and long-term reliability.

Low cost turbine flow sensor.

Pulse output. Fast response.

For low viscosity and low corrosive liquid .

Such as water, diesel,alcohol.

Wafer process connection.

Small size and light weight.

High pressure liquid flow measurement.

Liquid turbine flow sensor DN4-8 inches.

Thread connection for easy install.

Liquid turbine flow size 4mm to 3”.

Stainless steel liquid flow meter.

For fuel, diesel, water, kerosene, solvent.

Turbine flow meter for natural gas.

Temperature & pressure compensation.

High accuracy : ±1.5%R, ±1.0%R

Natural gas flow meter: 3/4” to 16 inches.

Turbine meter MODBUS RTU RS485.

Display shows flow rate and total flow.

High accuracy: 0.5% of Reading

Low cost flow meter for clean, low viscosity liquid.

TUF with HART and 4-20mA.

Stainless steel flow meter.

Low cost liquid flow meter for water, diesel ,fuel….

Liquid meter 4-20mA analog output.

Volumetric in-line liquid flow meter.

Low cost flow transmitter.

For clean and non-corrosive liquid.

3/8 inch low flow liquid flow meter.

Low flow detects from 150LPH.

Screw connection.

For water, chemical addictive, diesel.