Why need to measure sodium hydroxide flow?

Sodium Hydroxide (NaOH) is a highly versatile and widely used chemical in industries such as chemical manufacturing, water treatment, pulp and paper, and more. Accurate flow measurement of Sodium Hydroxide is essential to ensure precise dosing and control in various processes. However, the nature of Sodium Hydroxide, a highly caustic and viscous substance, poses challenges when it comes to

flow measurement. This is where

mass flow measurement becomes critical.

Why is Mass Flow Measurement Needed for Sodium Hydroxide?

Sodium Hydroxide is commonly used in applications where precise chemical reactions or mixing are required. Mass

flow measurement for chemical is particularly important because it accounts for the density and temperature of the fluid, providing a direct measure of the amount of substance passing through a pipeline. Volume-based flow measurement methods, such as

electromagnetic flow meter might be less accurate in these cases because they do not account for variations in fluid density, which can be influenced by temperature changes or concentration differences.

In many applications, Sodium Hydroxide is mixed with other chemicals, and a small discrepancy in measurement can lead to significant deviations in product quality or safety.

Mass flow meters help ensure that the correct quantity of Sodium Hydroxide is being added, improving process control and safety, while reducing waste and operational costs.

Challenges in Measuring Sodium Hydroxide Flow

Several difficulties arise when measuring the flow of Sodium Hydroxide, primarily due to its corrosive nature and varying viscosity. Some of the key challenges include:

1. Corrosiveness: Sodium Hydroxide is highly caustic, which means it can cause corrosion in many types of materials. Conventional flow meters, such as

turbine flow meter,

oval gear flow meters made from standard metals or plastics may degrade over time, leading to inaccurate measurements or equipment failure,

acid flow meters are needed here.

2. Viscosity Variation: The viscosity of Sodium Hydroxide can vary depending on its concentration and temperature. This makes flow measurement more complex, as the flow meter needs to handle these fluctuations without compromising accuracy.

3. Clogging and Deposits: In certain conditions, Sodium Hydroxide can crystallize or cause clogging in

mechanical flow meters, further complicating the flow measurement.

4. Temperature Sensitivity: Since the flow characteristics of Sodium Hydroxide change with temperature, devices that only measure flow volume may produce unreliable results when temperature shifts occur in the process line.

Why Choose Coriolis Mass Flow Meters for Sodium Hydroxide?

Coriolis mass flow meters are widely regarded as the best option for measuring Sodium Hydroxide flow due to their ability to measure mass directly, regardless of the fluid's viscosity, density, or temperature. Coriolis meters operate by using two vibrating tubes to detect the mass flow rate based on the Coriolis effect—an inertial force that acts on moving objects in a rotating frame of reference. The unique design of Coriolis meters makes them ideal for measuring challenging fluids like Sodium Hydroxide.

Coriolis Flow Meter Features for Sodium Hydroxide Measurement

1.

High Accuracy caustic soda flow meter: Coriolis flow meters offer highly precise mass flow measurement, which is essential for industries that rely on accurate dosing of Sodium Hydroxide. These mass flow meters can measure with an accuracy of up to 0.1%, ensuring that processes remain consistent and efficient.

While

electromagnetic flowmeters (magmeters) are capable of measuring sodium hydroxide solutions, their fundamental operating principle inherently limits their performance in custody transfer measurement and batch control applications, manifesting as delayed response characteristics and compromised measurement accuracy.

2. Resistance to Corrosion flow meter: Coriolis mass flow sensors are available in corrosion-resistant materials such as stainless steel or Hastelloy, which can withstand the harsh chemical properties of Sodium Hydroxide, minimizing the risk of damage and ensuring long-term reliability.

3. No Moving Parts mass flow meter: One of the major advantages of Coriolis meters is that they have no moving parts. This reduces the risk of mechanical wear and tear, which is particularly important when dealing with corrosive fluids like Sodium Hydroxide.

4. Viscosity Independence: Since Coriolis meters measure mass flow directly, changes in the viscosity of Sodium Hydroxide do not affect the accuracy of the measurement. This is critical for ensuring consistent performance across varying concentrations and temperatures.

5. Easy Maintenance: The lack of moving parts and resistance to corrosion mean that Coriolis flow meters require less frequent maintenance, reducing downtime and overall operational costs.

Silver Automation Instruments: Reliable Sodium Hydroxide Mass Flow Meters at Factory Price

Silver Automation Instruments provides robust

Coriolis mass flow meters that are well-suited for Sodium Hydroxide applications. These mass flow sensors are designed to offer long-lasting performance, even in challenging environments. They are made from corrosion-resistant materials and provide highly accurate mass flow measurements. Additionally, by offering these flow metering instruments at factory prices, Silver Automation Instruments ensures that industries can access high-quality flow meters at competitive rates, without compromising on performance or durability.

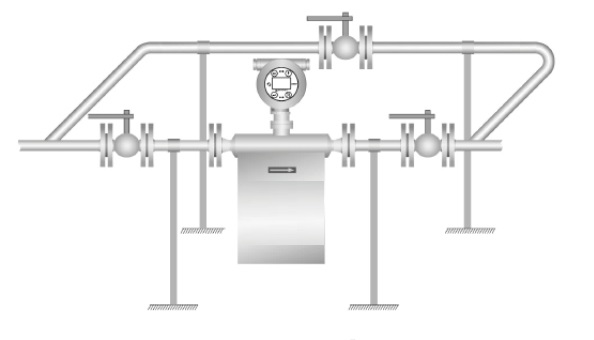

How to install sodium hydroxide mass flow meter ?

1. Shutoff valves shall be installed at both inlet and outlet piping connections.

2. Structural support brackets must be properly implemented to mitigate mechanical stress.

3. Mandatory zero-point calibration procedure shall be executed following initial installation and prior to commissioning.

4. Piping connections shall maintain coaxial alignment with mass flow meter connection. External forces must not be imposed on the mass flow sensor body, as parasitic mechanical loads may degrade measurement accuracy through induced mechanical stress.

In summary, measuring the flow of Sodium Hydroxide presents unique challenges due to its corrosive nature and viscosity variations. Coriolis mass flow meters stand out as the most reliable solution, offering precision, durability, and ease of use. Silver Automation Instruments’ offering provides a cost-effective and reliable choice for Sodium Hydroxide mass flow measurement.

Chemical resistant flow meter2024/02/07Chemical Resistant Flow Meters: Safeguarding Accuracy in Corrosive Fluid MeasurementIn industries handling corrosive substances like sulfuric acid, hydrochloric acid, phosphoric acid, sea water, hydro...view

Chemical resistant flow meter2024/02/07Chemical Resistant Flow Meters: Safeguarding Accuracy in Corrosive Fluid MeasurementIn industries handling corrosive substances like sulfuric acid, hydrochloric acid, phosphoric acid, sea water, hydro...view High Accuracy mass flow meter/flow controller2025/03/02High-precision gas flow meter/controller with accuracy of ±0.5% of full scale. Thermal dispersion principle for gas, air ,CO2,N2,O2,He,HCl,H2 etc. Response time 0.2s.view

High Accuracy mass flow meter/flow controller2025/03/02High-precision gas flow meter/controller with accuracy of ±0.5% of full scale. Thermal dispersion principle for gas, air ,CO2,N2,O2,He,HCl,H2 etc. Response time 0.2s.view Anti corrosive mass flow meter2024/07/13Coriolis flow meters are crucial in the acid-alkali and chemical industries for accurately measuring corrosive liquids. Their benefits include high precision, no moving parts, anti-corrosive material ...view

Anti corrosive mass flow meter2024/07/13Coriolis flow meters are crucial in the acid-alkali and chemical industries for accurately measuring corrosive liquids. Their benefits include high precision, no moving parts, anti-corrosive material ...view Coriolis mass flow controller2023/07/13Low flow Coriolis mass flow controller (MFC) adopts PID algorithm to control the solenoid valve, and accurately and quickly controls the mass flow rate of the fluid with low flow rate.view

Coriolis mass flow controller2023/07/13Low flow Coriolis mass flow controller (MFC) adopts PID algorithm to control the solenoid valve, and accurately and quickly controls the mass flow rate of the fluid with low flow rate.view Coriolis mass flow meter for chlorine gas measurement2023/06/08Coriolis flow meters can be suitable for measuring the flow of chlorine gas. However, there are a few important considerations to keep in mind when using a Coriolis flow meter for chlorine gas flow me...view

Coriolis mass flow meter for chlorine gas measurement2023/06/08Coriolis flow meters can be suitable for measuring the flow of chlorine gas. However, there are a few important considerations to keep in mind when using a Coriolis flow meter for chlorine gas flow me...view Liquid mass flow meter-Coriolis flow meter2020/02/19The Coriolis flow meter is widely regardedas the most accurate and highest-tech liquid mass flow meter on the markettoday. Applicable across a wide variety of industrial and municipal venues, theCorio...view

Liquid mass flow meter-Coriolis flow meter2020/02/19The Coriolis flow meter is widely regardedas the most accurate and highest-tech liquid mass flow meter on the markettoday. Applicable across a wide variety of industrial and municipal venues, theCorio...view