What is the best Oil Flow meter?

When measuring oil flow, there are many options to choose from, such as liquid turbine flow meters, oval gear flow meters, and Coriolis flow meters. Each type operates on a different principle and is suitable for measuring different kinds of oil.

But

which one is the best oil flow meter?

The answer is that :Coriolis flow meters are the best oil flow meters.

Coriolis flow meter has the highest accuracy. It offers the highest precision, with an accuracy of up to 0.1%, while oval gear flow meters have an accuracy range of 0.2% to 0.5%, and liquid turbine flow meters typically achieve around 0.5%. High accuracy oil flowmeter is often needs when custody transfer flow meter is demanded.

One of the biggest advantages of the Coriolis flow meter is its ability to directly measure the mass flow of oil. Oil mass flow measurement provides the best accuracy measurement; however oval gear flow meter and liquid turbine flow meter can only provide volume measurement.

In addition to flow measurement, Coriolis flow meter can also measure multiple parameters, including oil temperature, oil pressure, and viscosity. This makes it a highly functional and efficient option for oil flow measurement. However tranditional oil flow meter can only measure oil total flow and oil flow rate.

Contaminated oil often contains impurities, which can be fatal to flow sensors with moving parts. For example, the impeller of a liquid turbine flow meter can be damaged, and the gears of an oval gear flow meter can get stuck.

While Coriolis flow meter can also handle oil containing impurities, which is a significant advantage over the oval gear flow meter and TUF flow meter. Oval gear meters can easily get stuck when measuring dirty or contaminated oil, leading to operational issues and maintenance problems.

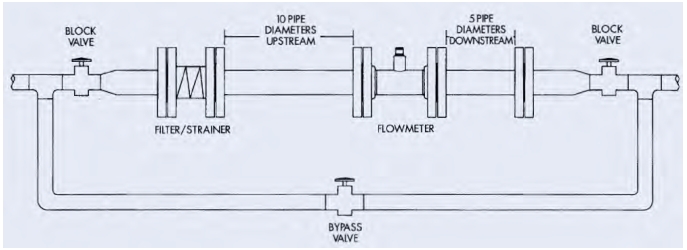

In terms of installation, the Coriolis flow meter does not require straight pipe sections, just like the oval gear flow meter. This simplifies the installation process and provides greater flexibility in different industrial setups. In contrast, liquid turbine flow meters require straight pipe sections both before and after the meter to ensure accurate measurement.

Another key advantage of the Coriolis flow meter is its ability to measure high-viscosity oil. Liquid turbine flow meters can only measure clean oil with a viscosity of up to 45 cP,so we normally use TUF flow meter as low viscosity oil flow meter, such as diesel flow meter, fuel flow meter, kerosene flow meter, vegetable oil flow meter, while oval gear flow meters can handle oil with viscosities of up to 2000 cP, oval gear flow meter can be used as analog diesel oil flow meter, analog fuel flow meter, crude oil flow meter, palm oil flow meter and so on. However, Coriolis flow meters can measure oils with viscosities in the tens of thousands of cP, such as lube oil, grease ,HFO flow measurement, paraffin oil flow measurement, polymer-based oil flow measurement and so on, making them suitable for a wide range of industrial applications, in a world it can measure all kinds of oil .

High temperature oil flow meter

Liquid turbine flow meters can measure oil at temperatures up to 150°C, while oval gear flow meters can handle high-temperature oils up to 200°C. Vortex flow meters, designed for low-viscosity oils, can operate at temperatures up to 350°C. However, Coriolis flow meters can also measure oils at temperatures as high as 350°C with oil kinds oil viscosity, making them suitable for applications such as furnace oil flow measurement or other high temperature oil flow measurement.

Overall, the Coriolis flow meter is the most accurate and reliable option for oil flow measurement. Its ability to measure mass flow, handle impurities, and accommodate high-viscosity oils makes it the best choice for industries that require precise and efficient oil flow monitoring.

The

Coriolis flow meter is undoubtedly the best choice for measuring oil flow, but

it is also the most expensive. Users can select the most suitable oil flow

meter based on their specific applications, requirements and your budget. Visit www.silverinstruments.com and let us know your needs—we will help you choose the best oil flow meter for

your application.

|

Feature |

|||

|

Accuracy |

±0.1%~0.5% |

±0.5~1.0% |

±0.2% to ±0.5% |

|

Measurement Type |

Mass flow |

Volume flow |

Volume flow |

|

Multi-Parameter Measurement |

Yes (Flow, Temperature, Pressure, Viscosity) |

No (Only Flow) |

No (Only Flow) |

|

Handling Contaminated Oil |

Yes (No moving parts) |

No (Impeller can be damaged) |

No (Gears can get stuck) |

|

Viscosity Range |

Up to tens of thousands of cP |

Up to 45 cP |

Up to 2000 cP |

|

Maximum Temperature |

Up to 350°C |

Up to 150°C |

Up to 200°C |

|

Straight Pipe Requirement |

No |

Yes (Requires long straight pipe sections) |

No |

|

Application Suitability |

All types of oil (including high-viscosity and contaminated oil) |

Low-viscosity, clean oil (e.g., diesel, fuel, kerosene) |

Medium-viscosity and clean oil (e.g., crude oil, palm oil, fuel oil) |

|

Cost |

High |

Low |

Low to medium according to the mateiral |

Coriolis Oil Flow Meter for Accurate Mass Measurement2023/11/21Coriolis Oil Flow Meter: A Precise Solution for Oil Mass MeasurementCoriolis oil flow meter, a vital tool in the realm of fluid dynamics, serves a crucial purpose in accurately measuring oil mass flow...view

Coriolis Oil Flow Meter for Accurate Mass Measurement2023/11/21Coriolis Oil Flow Meter: A Precise Solution for Oil Mass MeasurementCoriolis oil flow meter, a vital tool in the realm of fluid dynamics, serves a crucial purpose in accurately measuring oil mass flow...view Oval gear flow meter2020/12/23Oval gear flowmeter is a kind of positivedisplacement flowmeter, used for precise continuous or intermittent flow measurementof liquid in the pipeline. It is especially suitable for heavy oil, polyvin...view

Oval gear flow meter2020/12/23Oval gear flowmeter is a kind of positivedisplacement flowmeter, used for precise continuous or intermittent flow measurementof liquid in the pipeline. It is especially suitable for heavy oil, polyvin...view Liquid Turbine Flow Meter2017/04/12Liquid Turbine flow meter is a kind of low cost digital flow meter for diesel ,petrol,water,palm oil. it is for clean, low viscosity ,non-corrosive liquid.view

Liquid Turbine Flow Meter2017/04/12Liquid Turbine flow meter is a kind of low cost digital flow meter for diesel ,petrol,water,palm oil. it is for clean, low viscosity ,non-corrosive liquid.view Mechanical Oil Flow Meters2025/01/03Overview of Flow MetersFlow meters play a vital role in accurately measuring the flow of liquids, air and gases across many applications. A mechanical oil flow meter is designed specifically for track...view

Mechanical Oil Flow Meters2025/01/03Overview of Flow MetersFlow meters play a vital role in accurately measuring the flow of liquids, air and gases across many applications. A mechanical oil flow meter is designed specifically for track...view Low flow oil flow meter2021/12/26Oval gear flow meter is a kind of inline digital low flow oil flow meter. The oil min flow it can measure is 0.03 Liter/h (0.5-150 mL/min), it is very ultra low flow oil flow meter.view

Low flow oil flow meter2021/12/26Oval gear flow meter is a kind of inline digital low flow oil flow meter. The oil min flow it can measure is 0.03 Liter/h (0.5-150 mL/min), it is very ultra low flow oil flow meter.view Crude Oil Flow Meter2023/03/21What is crude oil flow meter?A crude oil flow meter is a device used to measure the flow rate of crude oil in pipelines or other transportation systems. The flow meter works by measuring the volume or...view

Crude Oil Flow Meter2023/03/21What is crude oil flow meter?A crude oil flow meter is a device used to measure the flow rate of crude oil in pipelines or other transportation systems. The flow meter works by measuring the volume or...view