Biogas Flow Meter

Related Products

Low cost flow meter for gas and air

Insertion or inline type

4-20mA & MODBUS

For air,N2,CO2,biogas,natural gas .,etc

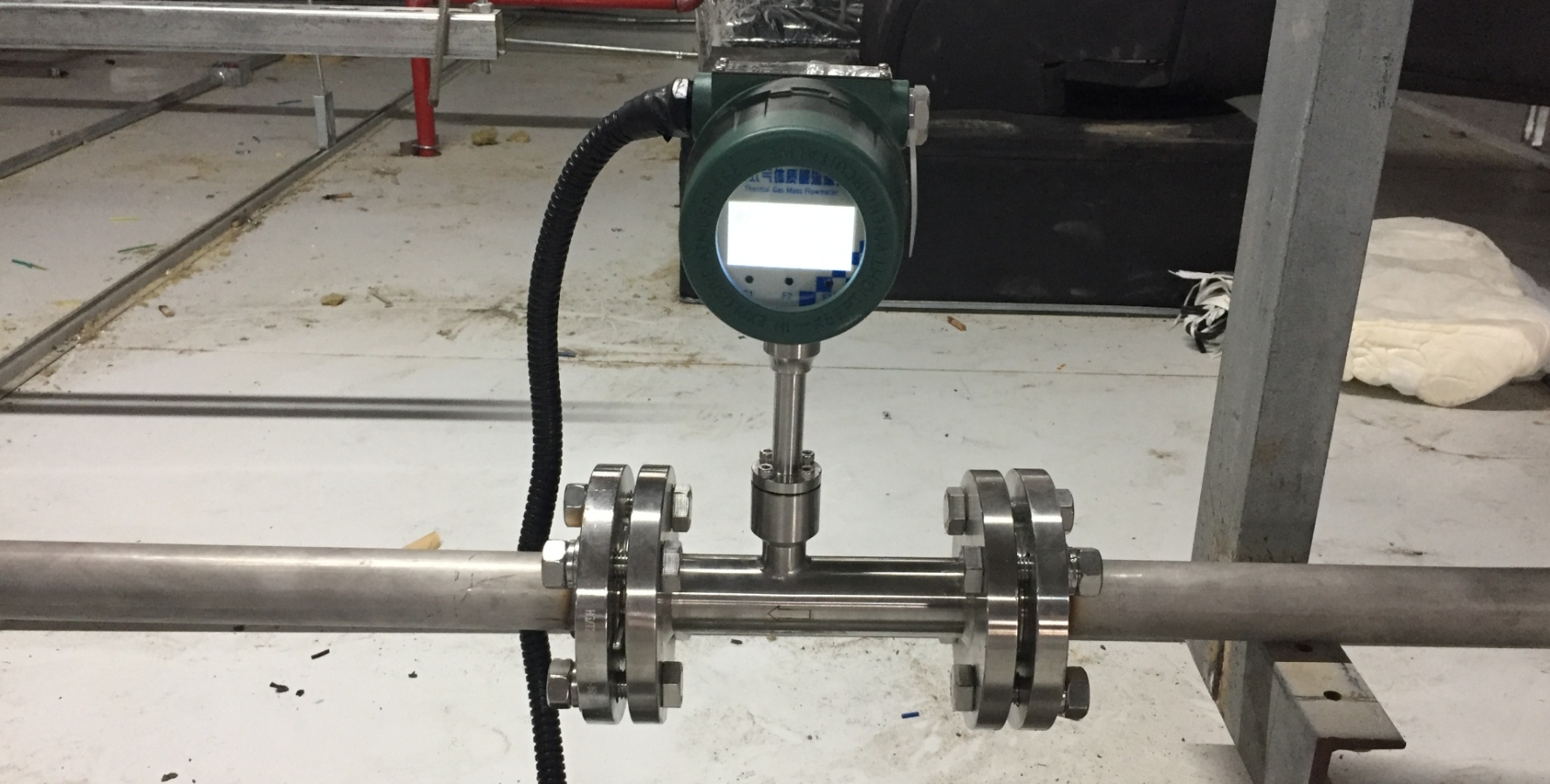

In-line type thermal dispersion flow meter

Gas mass flow measurement.

Flange or thread process connection.

Large turndown ratio-100:1.

Without any temp & press compensation.

Biogas, a renewable energy source primarily

composed of methane (CH₄) and carbon

dioxide (CO₂), requires

accurate flow measurement to optimize energy utilization, process control, and

safety monitoring. For instance, in wastewater treatment plants or agricultural

biogas projects, precise biogas flow data is critical for evaluating gas

production efficiency, optimizing equipment performance, and calculating

greenhouse gas emissions. Additionally, biogas often contains toxic gases like

hydrogen sulfide (H₂S). Real-time

flow monitoring helps prevent leaks, mitigating risks of explosions or

poisoning, thereby ensuring personnel safety.

Biogas is characterized by low flow rates, low pressure, and complex composition, often containing moisture, particulates, and corrosive gases (e.g., H₂S). Traditional flow meters struggle with these conditions:

- Low Flow Rates measurement: Fluctuating biogas production demands high sensitivity at low velocities, which conventional flow meters lack, for example vortex flow meter is hard to measure low flow gas , leading to measurement gaps.

- Contamination and Corrosion: Particulates clog sensors, while H₂S corrodes metal components, reducing biogas flow instrument lifespan.

- Pressure Instability: Biogas systems typically operate at low pressures (for example biogas flow measurement at pressure around 1-2 Kpa), requiring biogas flow sensors with broad pressure-loss adaptability.

Thermal mass flow meters, based on the thermal dispersion principle, measure mass flow directly by detecting temperature differences caused by gas cooling effects. They are uniquely suited for biogas applications:

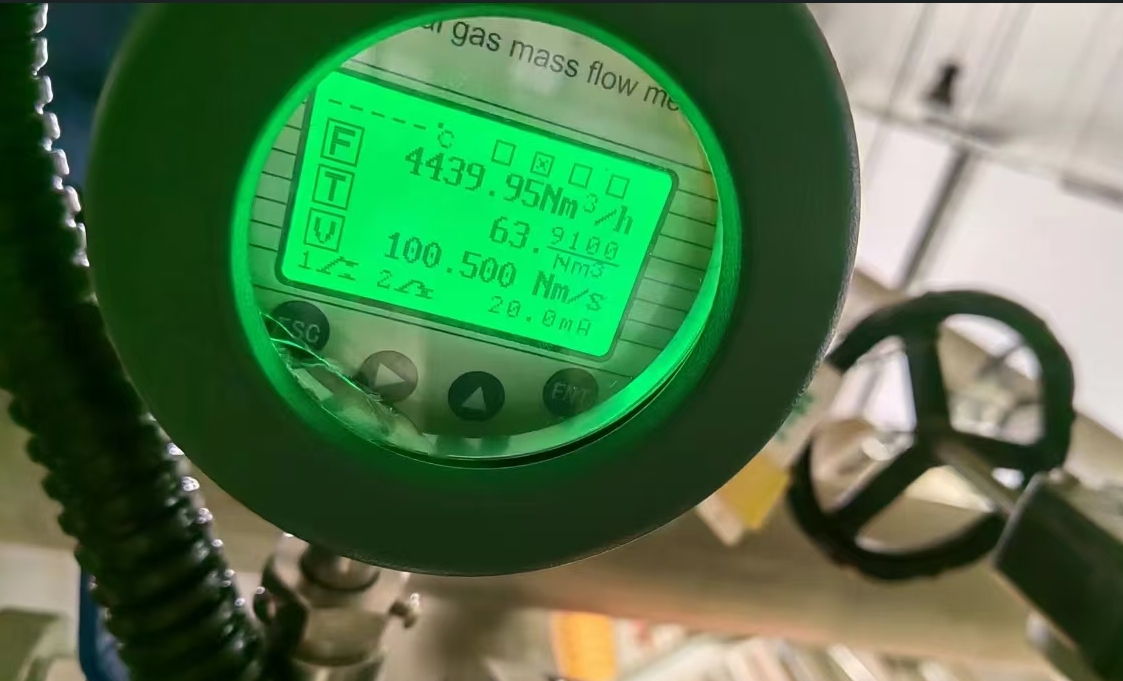

- No Temperature/Pressure Compensation to realize biogas flow measurement: Direct mass flow output eliminates errors from temperature or pressure fluctuations when measuring biogas flow , by using thermal mass flow meter we directly get flow unit Nm3/h, while by using other flow meters, such as orifice plate , we need temperature sensor and pressure sensor to calculate Nm3/h flow.

- Wide Range and High Sensitivity: A turndown ratio of 100:1 and velocity range of 0.05–80 m/s enable precise detection of low-flow biogas flow measurement. And it is very interesting to know that the lower pressure , the more accurate measurement of biogas flow measurement by thermal mass flow meter.

- Corrosion and Contamination Resistance: mass flow Probes made of 316L stainless steel and coat Teflon to resist H₂S corrosion, while a lack of moving parts minimizes clogging risks.

- Low Pressure Loss: Insertion-type thermal mass flow sensor designs minimally disrupt fluid flow, ideal for low-pressure pipelines.

- Additional Advantages of Insertion-Type Thermal Flow Meters for Large-Diameter Biogas Pipelines

- Insertion gas flow meters excel

in large-diameter biogas pipelines (e.g., 4", 6", 8", 10")

due to cost-effective installation, minimal flow disruption, and scalability

without requiring full-bore pipe modifications, ideal for retrofitting or

expansive systems.

- Wide measurement Range for different flow sensor size, covering typical biogas project requirements, below is the flow range table for different thermal mass flow sensor

|

Sensor size (mm) |

25 |

40 |

50 |

80 |

100 |

150 |

200 |

250 |

300 |

400 |

|

Biogas flow range(Nm3/h) |

51 |

129 |

206 |

516 |

860 |

1720 |

3440 |

5160 |

7430 |

13209 |

- Accuracy: ±1% of

reading with ±0.5% repeatability, suitable for different

process control.

- Digital display to show biogas flow rate , flow velocity and total flow

- Environmental Adaptability: Operates at -40°C to 350°C and up to 630 bar pressure, suitable for outdoor or high-temperature environments.

- Output and Protection: 4–20 mA, HART, or RS485 signals; I

-P65 rating;

Explosion-proof certification (Exd IICT6), ATEX approved thermal mass flow meter by biogas flow measurmeent

Conclusion

Thermal mass flow meters, with their high accuracy, robust interference resistance, and low maintenance costs, are ideal for biogas flow monitoring. Proper selection (e.g., insertion or inline models) and parameter customization ensure reliable performance in challenging biogas conditions, supporting energy recovery, operational safety, and environmental compliance. welcome to contact silverinstruments.com to get low cost biogas flow meter.

we will contact you within 24 hours.